Cast welding mold for lead-acid storage batteries and bridge welding method for buses

A lead-acid battery, casting and welding mold technology, applied in the field of lead-acid battery casting and welding molds and bus bar bridge welding, can solve the problems of difficult to guarantee casting welding quality, force deformation and other problems, achieve automatic control, save lead The effect of improving the efficiency of casting and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Taking a small-density battery as an example, the casting and welding mold and busbar cross-bridge casting and welding method involved in the present invention will be described in detail.

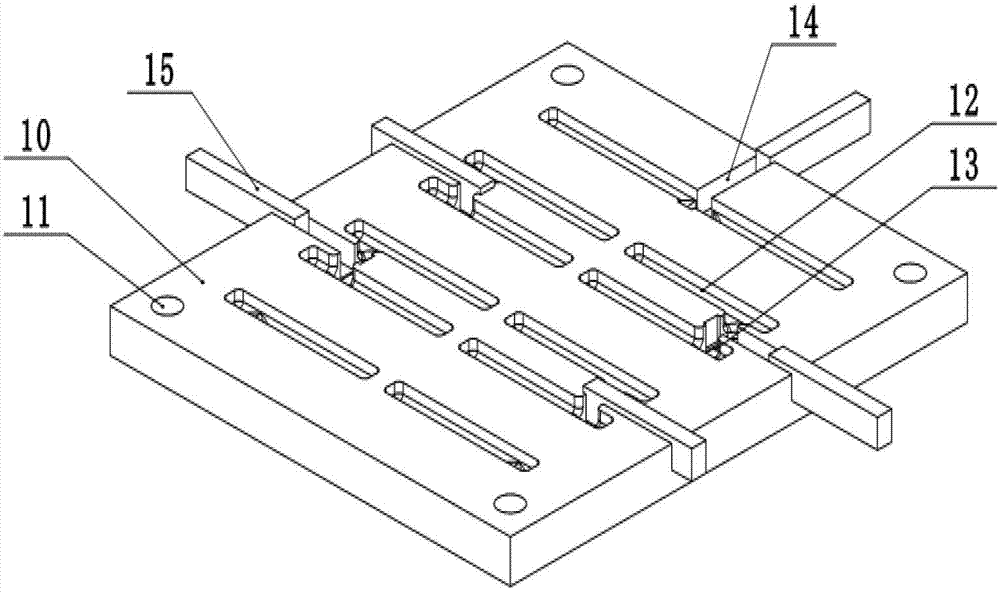

[0020] Such as figure 1 Shown is a casting and welding mold 10 and a spacer 15 for a small-density battery. The mold includes several busbars 12 and bridges 13, and the bridges 13 are deeper than the busbars 12 by a certain depth. A slot 14 is left in the middle part of 13 parallel to the bus bar 13 . One end of the slot 14 is located at the edge of the casting and welding mold 10, and the other end is located at the bridging position 13. The partition core 15 is horizontally plugged and installed in the slot 14, and the depth of the slot 14 is less than the bridging position 13 depth. The width of the slot 14 matches the thickness of the spacer core 15, and the thickness of the spacer core 15 is economically selected according to the thickness of the battery box partition plate 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com