An Adaptive Finger Mechanism for Space On-orbit Service Robot

A service robot, self-adaptive technology, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of few grasping modes, inability to achieve versatility, large working space, etc., to achieve a large grasping envelope range, self-adaptive Self-stable locking and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

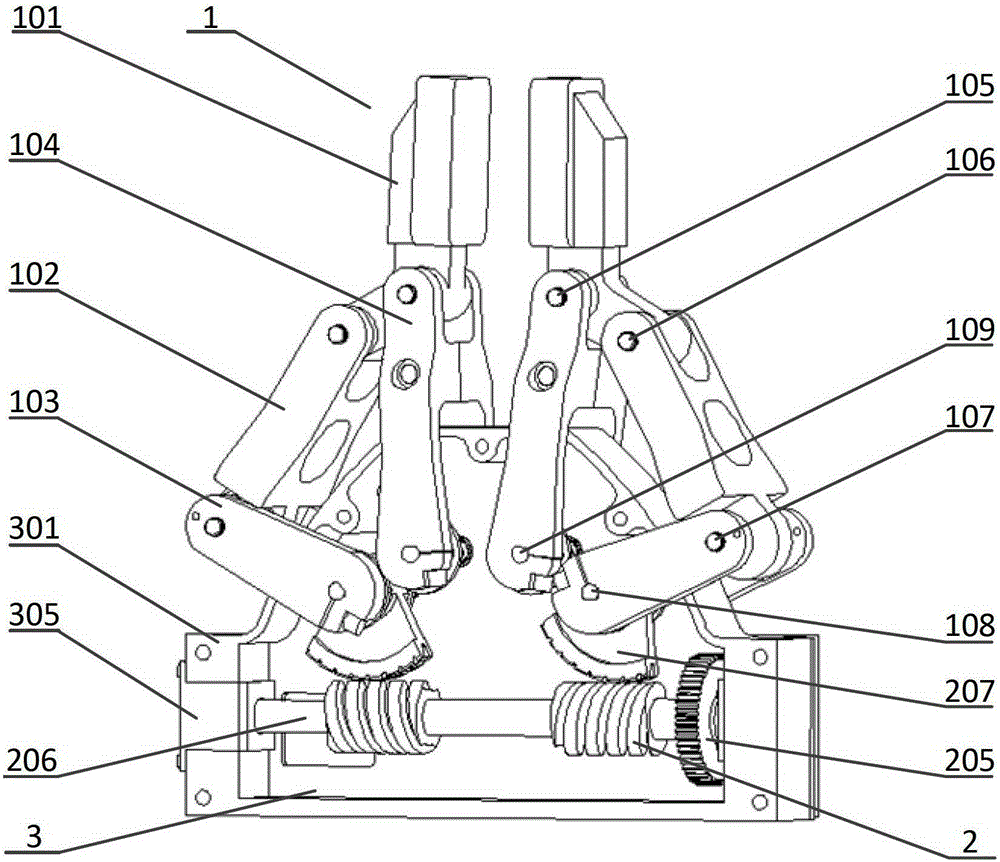

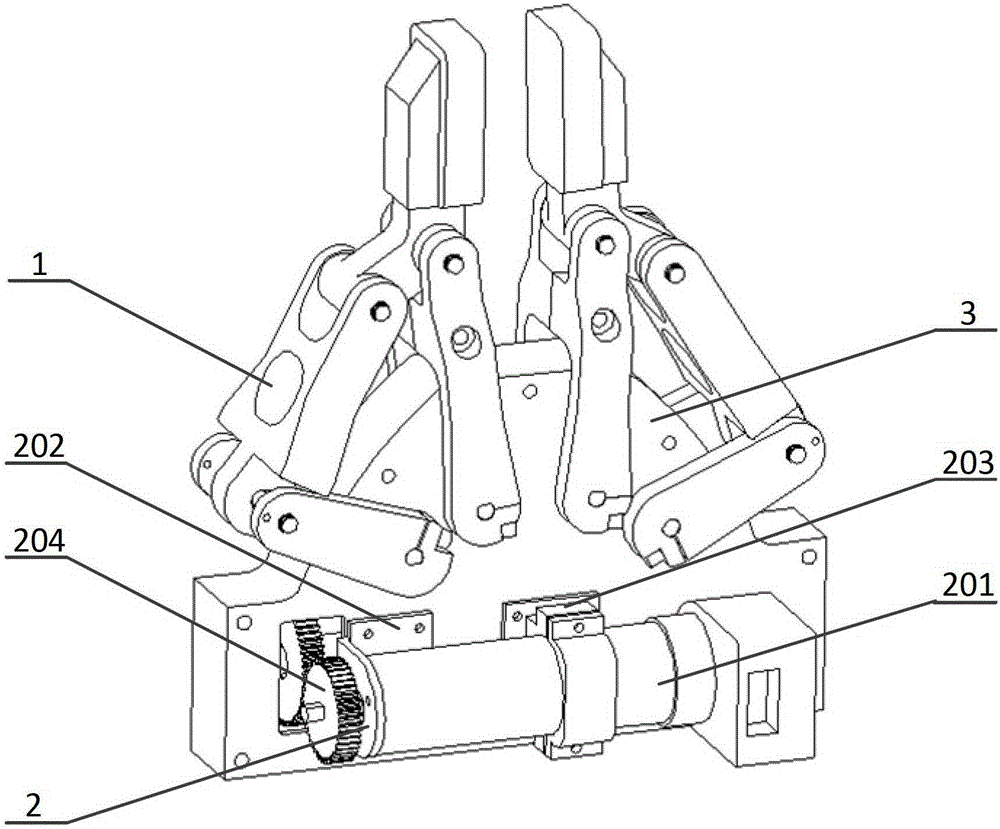

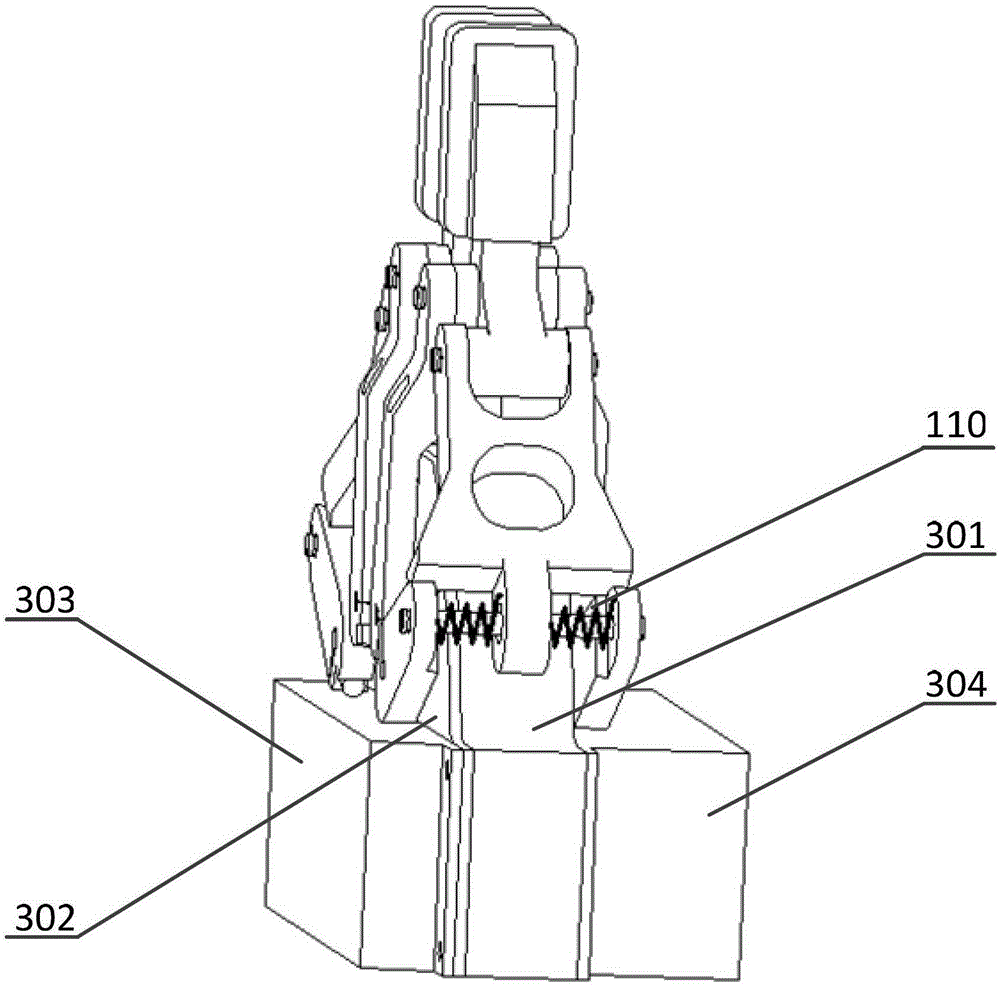

[0030] like Figure 1a , Figure 1b , Figure 1c As shown, it is a three-dimensional perspective view of the self-adaptive gripper mechanism of the space on-orbit service robot of the present invention, including: the self-adaptive gripper 1 , the motor and its transmission mechanism 2 , and the base part 3 .

[0031] The self-adaptive finger 1 is composed of two symmetrical and identical five-bar mechanisms. Each five-bar mechanism includes: a contact rod 101, an intermediate rod 102, an active rod 103, a driven rod 104, a driven pin 105, and an intermediate pin. 106, driving pin 107, driving shaft 108, driven shaft 109, torsion spring 110; the motor and its transmission mechanism 2 include: motor 201, L-shaped motor bracket 202, U-shaped motor bracket 203, pinion 204, large gear 205 , worm shaft 206 , worm wheel 207 ; the base part 3 includes: a palm base 301 , a palm front shell 302 , a palm front cover 303 , a palm rear cover 304 , and a worm shaft positioning base 305 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com