Tire blank press roll mechanism, as well as device and rolling method using tire blank press roll mechanism

A technology of roller mechanism and tire blank, which is applied in the field of rubber machinery, can solve the problems of affecting the quality of rolling, difficulty in controlling the intermediate process, lack of rubber, etc., and achieve the goal of improving rolling quality, improving rolling efficiency, and simplifying the structure of pressing rollers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

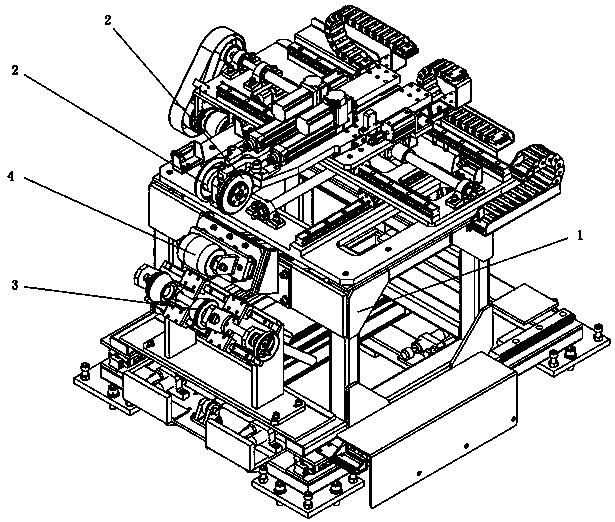

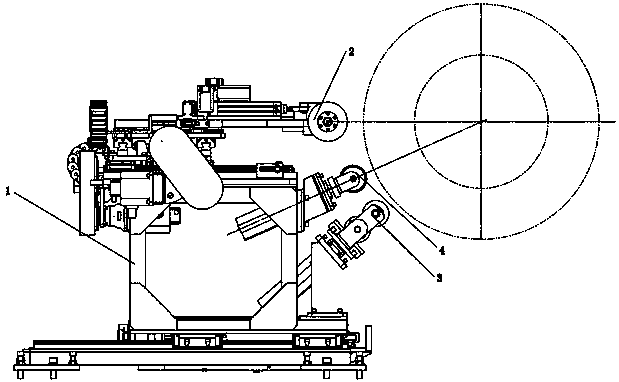

[0039] Such as Figure 1 to Figure 3 As shown, the tire blank combined roller mechanism device includes a frame 1, and the frame 1 is provided with a turn-up roller mechanism 2, a tread roller mechanism 4, and a shoulder roller mechanism 3, and the three are vertically upward. , middle and lower distribution, all have rollers arranged at the front end, and the rear end of the rollers is provided with a driving mechanism that sends them into the rolling station that is in contact with the outer surface of the tire embryo and implements the rolling operation.

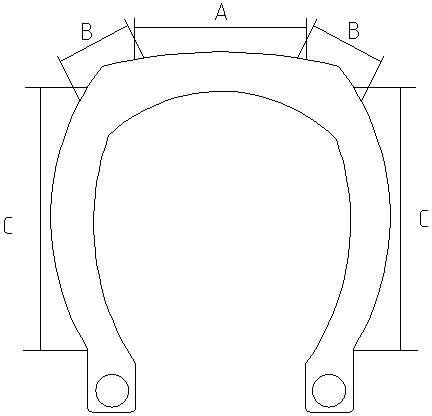

[0040] Such as figure 1 As shown, the embryo combined pressure roller device includes two sets of turn-up pressure roller mechanisms, which are respectively responsible for rolling both sides of the tread and the tire shoulder, that is, the B area on the left and right sides of the embryo; a set of tread pressure roller mechanism 2 is responsible for rolling The tread part is rolled, that is, area A; two sets of shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com