A kind of preparation method of electrospinning glue solution for preparing alumina ultrafine fiber

An electrospinning and ultra-fine fiber technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of poor flexibility, unfriendly environment, and reduced fiber strength, to ensure fiber-forming properties and Continuity, broad application prospects, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

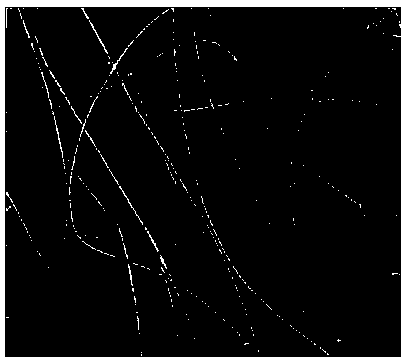

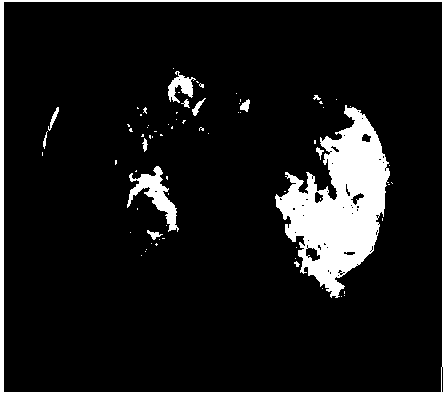

[0032] ⑴ Weigh the pseudo-boehmite powder (see the TEM photo figure 1(a)) 2.54g, measure 14mL of distilled water and stir the pseudo-boehmite powder to make slurry, the concentration of adding is 2.84mol L -1 7mL of nitric acid solution, heated and stirred to 80-85°C under condensing and reflux conditions, and then cooled to room temperature to obtain aluminum sol. Add 10mL of absolute ethanol to the prepared aluminum sol, stir well, then slowly add 0.28mL tetraethyl orthosilicate, continue to stir for 2 hours, then add 1.8g of PVP, stir and dissolve to obtain a translucent spinning dope (see attached figure 1 (b)).

[0033] (2) Inject the spinning glue prepared in step (1) into a 20mL plastic syringe, using a No. 16 stainless steel blunt needle, the feeding rate is 2.1mL / h, the voltage is 20kV, the receiving distance is 20cm, and the humidity in the spinning machine cavity 30%, electrospinning at a temperature of 52°C to prepare alumina precursor fibers.

[0034] (3) Pl...

Embodiment 2

[0037] Take 1.56g of pseudo-boehmite powder, measure 13mL of distilled water to stir the pseudo-boehmite powder, and add the concentration of 1.51mol L -1 13mL of nitric acid solution, heated and stirred to 80-85°C under the condition of condensing and reflux, and then cooled to room temperature to obtain aluminum sol. Add 1.34g of PVA to the prepared aluminum sol. After the PVA is fully swollen, raise the temperature of the system to about 80°C under slow mechanical stirring, stir until the PVA is completely dissolved, and cool to room temperature naturally, then slowly add 0.61mL of silica sol (SiO 2 The concentration is 1.0mol·L -1 ), and continue to stir for 1 hour to obtain a translucent spinning glue.

[0038] Step (2) is as described in Example 1, the difference is that the receiving distance is 13cm.

[0039] Step (3) is the same as in Example 1.

[0040] Gained Al 2 o 3 The diameter of the ceramic fiber is 200-500nm, Al 2 o 3 Content 97%, SiO 2 The content is...

Embodiment 3

[0042] ⑴Weigh 2.75g of pseudo-boehmite powder, measure 20mL of distilled water to stir the pseudo-boehmite powder into slurry, and add the concentration to 3.0mol L -1 6.0 mL of nitric acid solution, heated and stirred to 80-85°C under the condition of condensing and reflux, and then cooled to room temperature to obtain aluminum sol. Take 15mL of the prepared aluminum sol, add 9mL of absolute ethanol, stir well, then slowly add the concentration of 0.21mol L -1 ZrO(NO 3 ) 2 1.35mL, after continuous stirring for 2 hours, add 1.37g of PVP, stir until the PVP is completely dissolved, that is, the appearance of translucent spinning glue is obtained.

[0043] (2) Inject the spinning glue solution prepared in step (1) into a 20mL plastic syringe, using a No. 8 stainless steel blunt needle. Alumina precursor fibers were prepared by electrospinning under the conditions of a feeding rate of 2.4mL / h, a voltage of 20kV, a receiving distance of 13cm, a humidity of 30% in the spinning m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com