Coking furnace operating platform structure with diagonal draw bars

A technology of inclined rods and consoles, which is applied in coking ovens and petroleum industries, can solve problems such as increased investment, large material consumption, and unsatisfactory mechanical models, so as to reduce material consumption, simplify connection methods, and overcome difficulties in adjusting columns The effect of horizontal displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

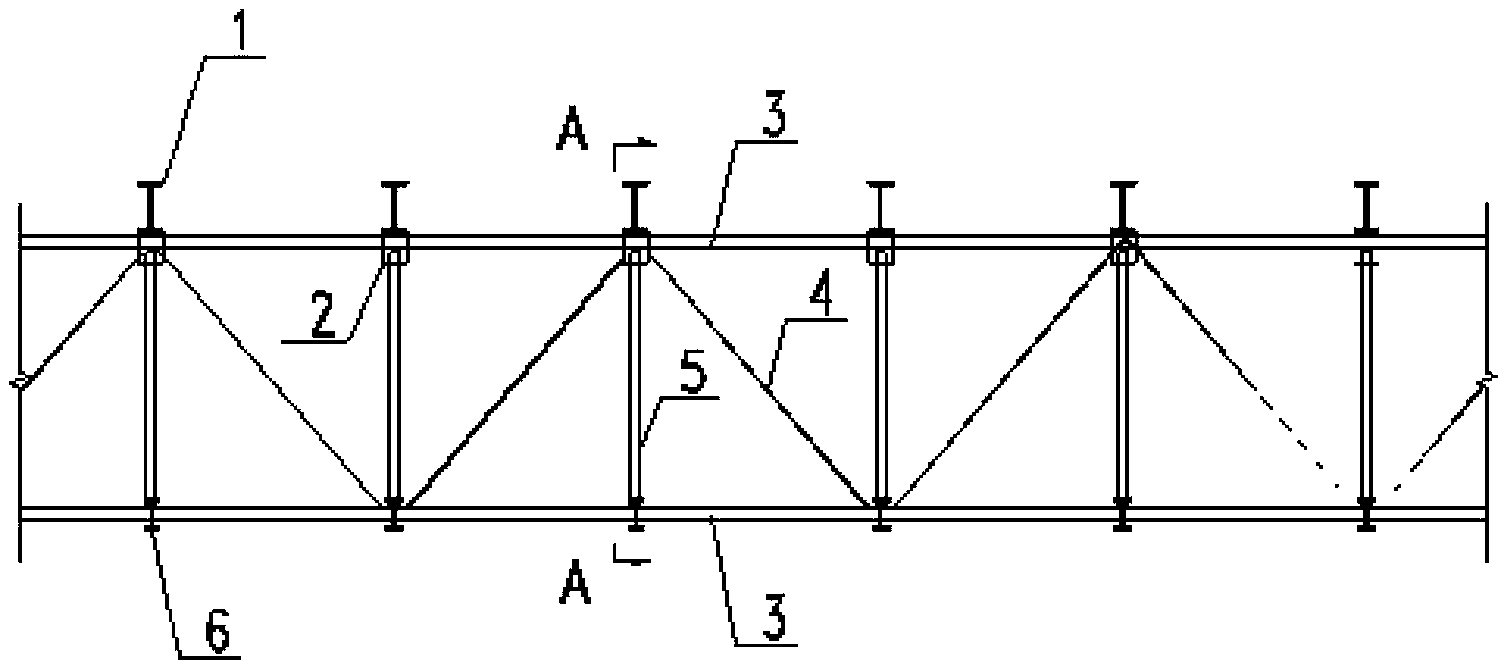

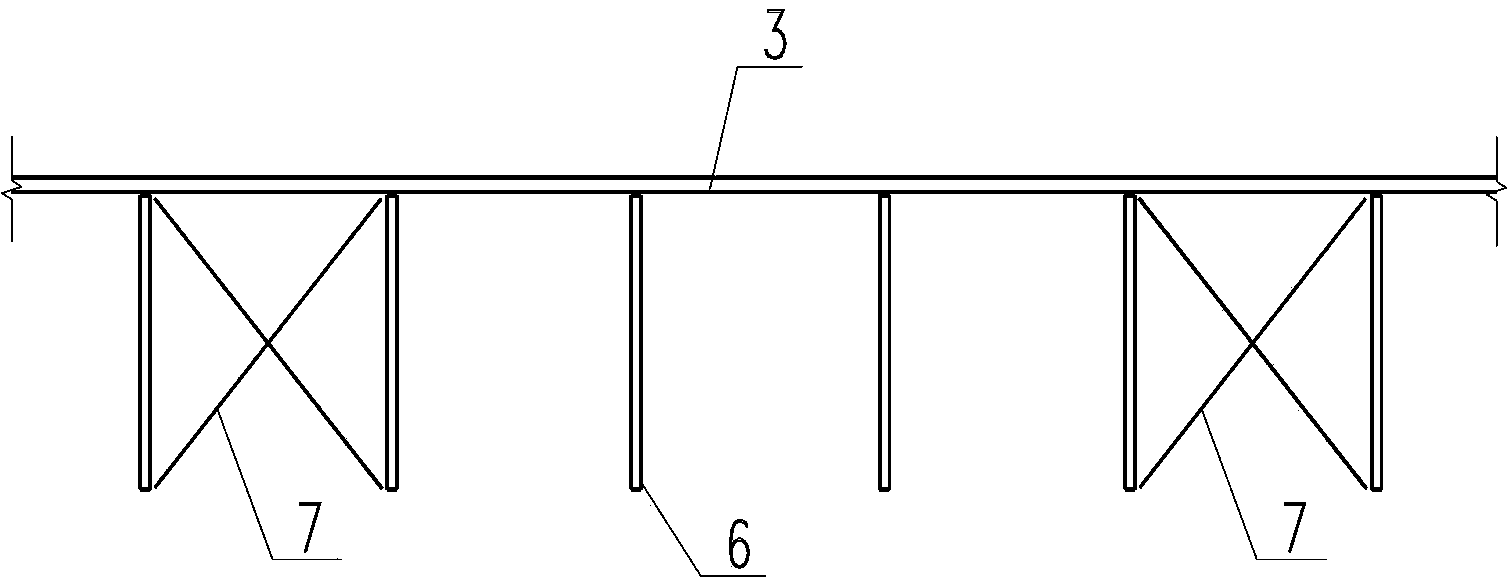

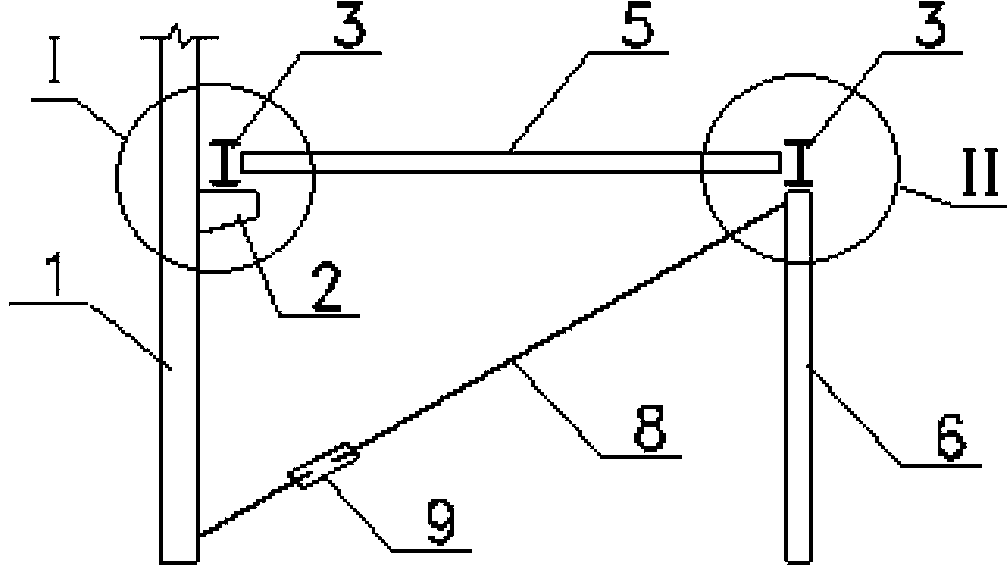

[0019] See Figure 1 to Figure 3 , is a schematic diagram of the upper plane structure of a coke oven operating table structure embodiment with inclined tie rods in the present invention, including longitudinal beams 3, transverse beams 5, horizontal support rods 4, vertical support rods 7 and upright columns 6. A plurality of transverse beams 5 are arranged in parallel between the longitudinal beams 3 arranged in parallel, one of the longitudinal beams 3 is carried on the steel corbel 2 of the furnace column 1, and the two ends of the transverse beams 5 are connected to the adjacent longitudinal beams 3 respectively. Connection, one end of the transverse beam 5 and the other end of two adjacent transverse beams 5 are cable-stayed and connected through the horizontal support rod 4 to form a horizontal truss structure, which can effectively ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com