Detergent dosage controller

A detergent injection and controller technology, which is applied in the direction of washing machine control devices, washing devices, tableware washing machines/rinsing machines, etc., can solve problems such as inaccurate injection accuracy, complex structure, and blocked equipment operation, and achieve compact structure , Simple structure and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

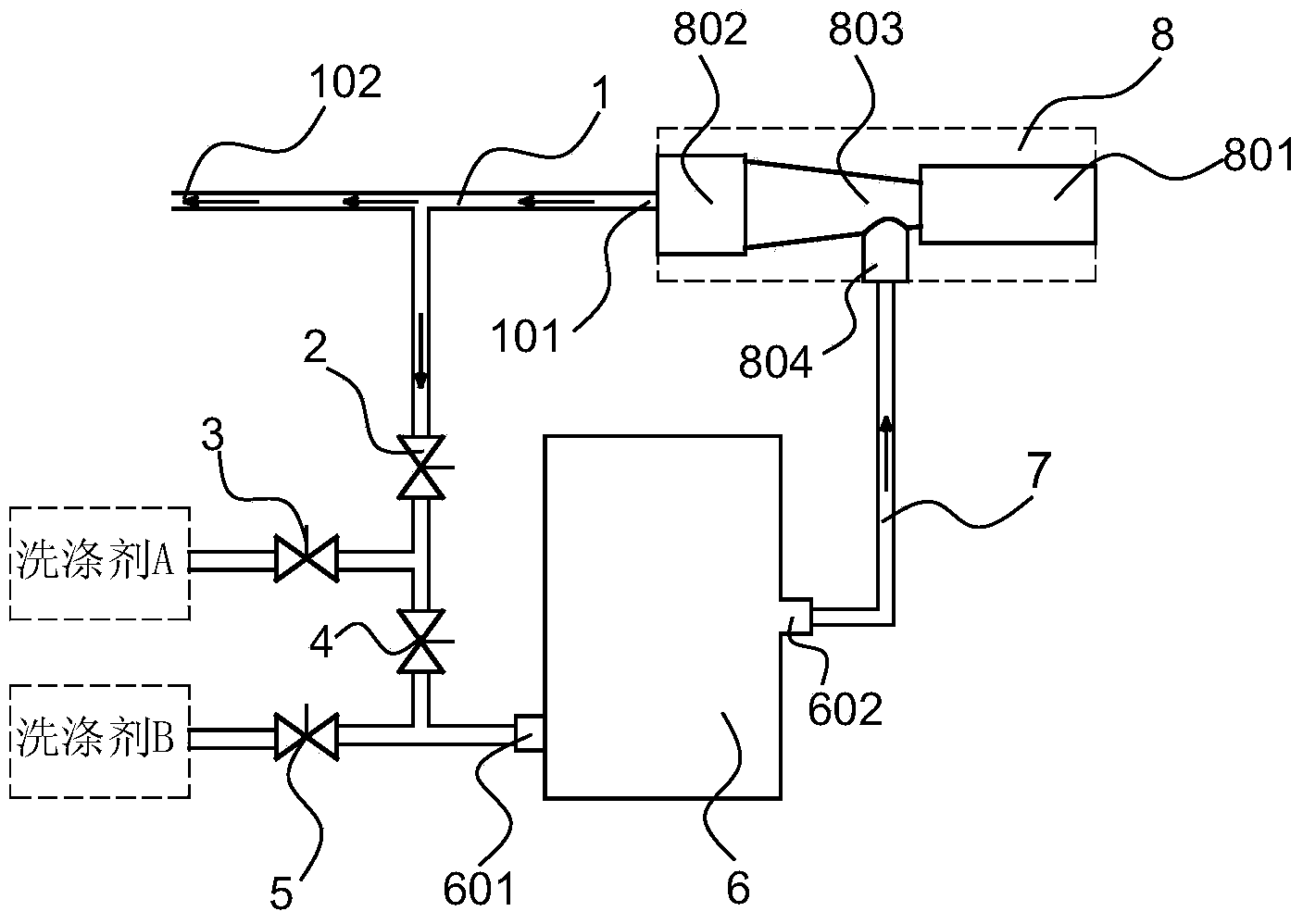

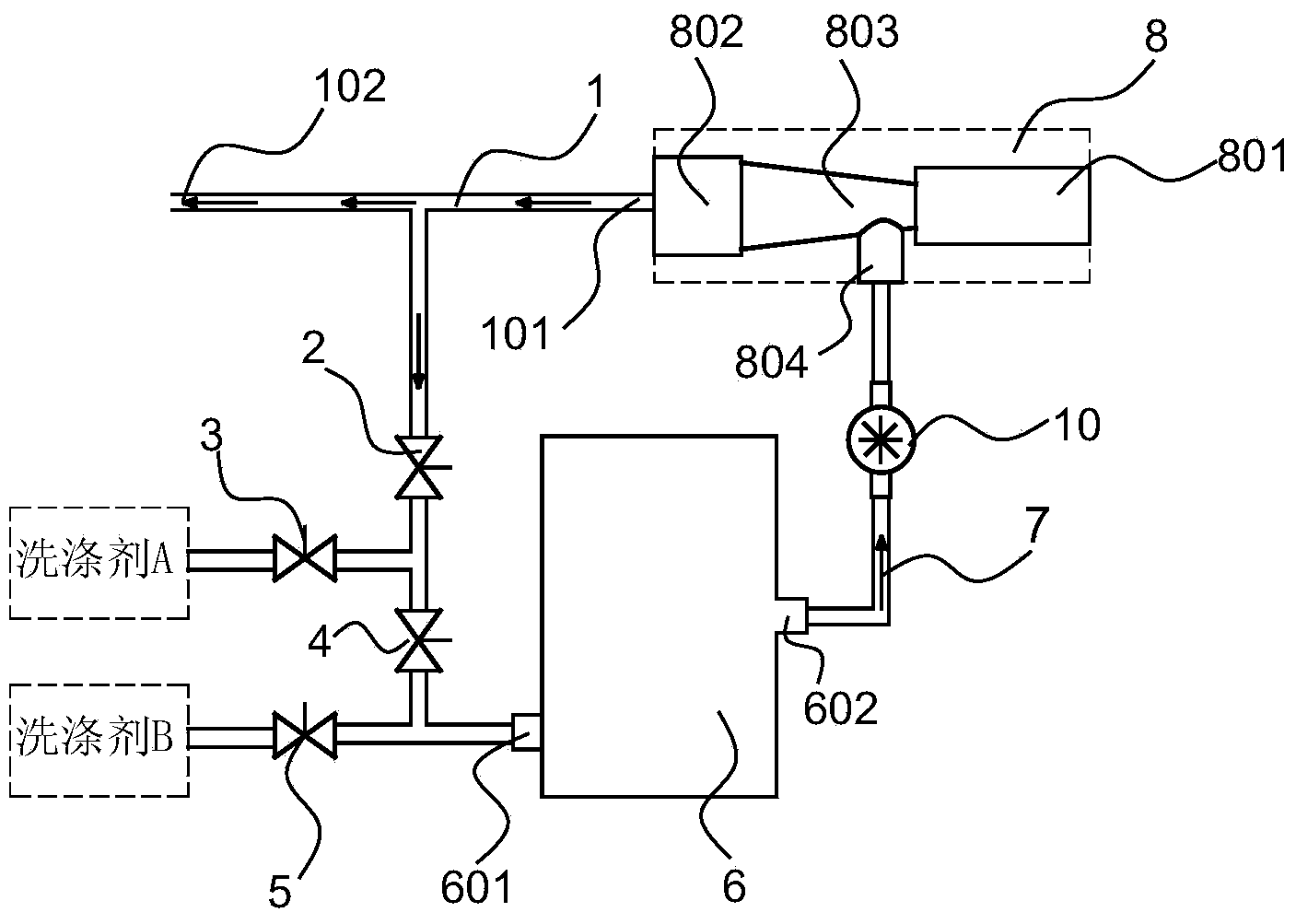

[0044] The detergent dispensing controller has a main channel 1, one end of the main channel is the inlet 101 of the input liquid flow, and the other end of the main channel is an outlet 102 that can be connected to the water inlet of the washing bucket, and is provided with valve A2, valve B3, valve C4, valve D5, liquid collecting chamber 6 and Venturi negative pressure generator 8, the inlet of valve A is connected with the main channel bypass, the inlet of valve B can communicate with the liquid storage tank of detergent A, the valve A and valve B The outlet is connected to the inlet of valve C, the inlet of valve D can be connected to the liquid storage tank of detergent B, the outlets of valves C and D are connected to the inlet 601 of the liquid collection chamber, and the outlet 602 of the liquid collection chamber passes through the return channel 7 is in communication with the negative pressure port 804 of the Venturi negative pressure generator, the outlet 802 of the ...

Embodiment 2

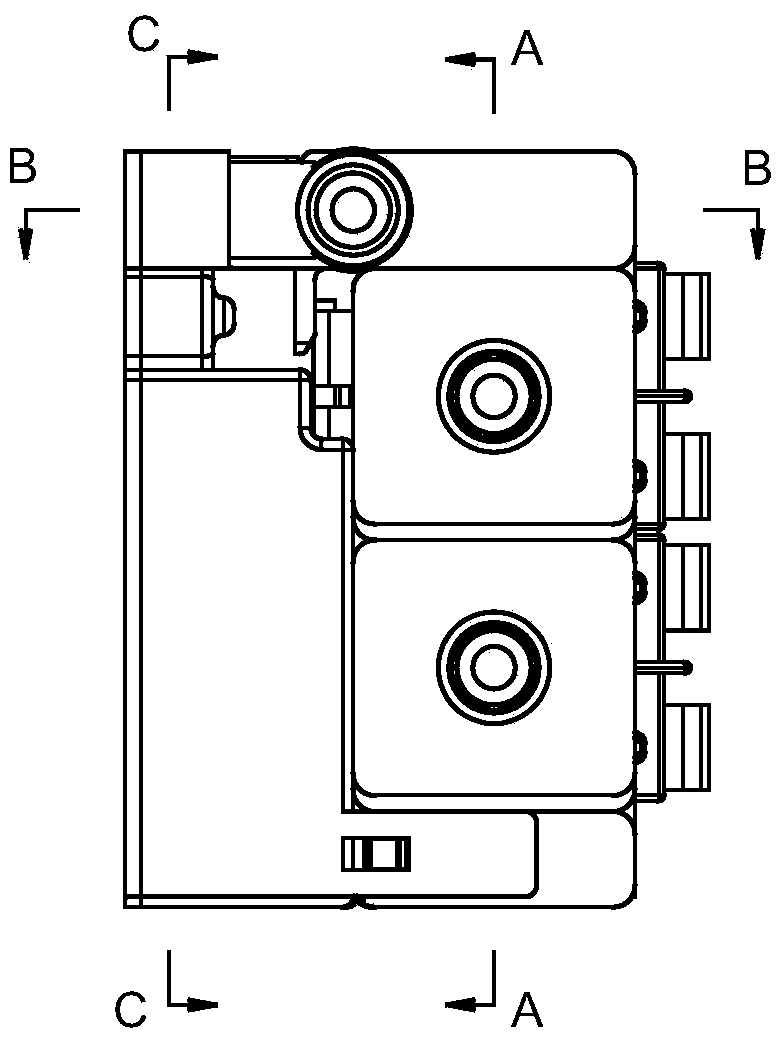

[0046] In this example, the detergent injection controller, see image 3 , 4 , 5, 6, with an integrated valve, the integrated valve is provided with a main channel 1, valve A2, valve B3, valve C4, valve D5, liquid collection chamber 6, return channel 7 and Venturi negative pressure generator 8, the main channel One end is the inlet 101 of the input liquid flow, and the other end of the main channel is the outlet that can be connected to the water inlet of the washing tub through a connecting pipe. The inlet 201 of the valve A is connected to the main channel through the bypass port 103 of the main channel 1, and the inlet of the valve B3 It can communicate with the liquid storage tank of detergent A. The outlets of valve A and valve B are connected to the inner cavity 17 and communicate with the inlet of valve C4. The inlet of valve D5 can be connected with the liquid storage tank of detergent B. Valve C The outlet of the valve D is connected to the inner chamber 2 18, the in...

Embodiment 3

[0053] In this example, the detergent injection controller, see Figure 7 , Figure 8 , is to add valve E20, valve F21 and solenoid valve assembly three including piston cap three 22, piston three 23, electromagnetic coil three 24 on the basis of example two; the outlets of valve C and valve D in this example are connected to inner chamber two 18 and It is connected with the inlet of valve E20, the inlet of valve F can be connected with the liquid storage tank of detergent C, the outlets of valve E and valve F are connected to the inner chamber 3 19, and the inner chamber 3 is connected with the inlet 601 of the liquid collecting chamber 6; The first cavity, the second cavity and the third cavity are connected together;

[0054] The valve E20 and the valve F21 correspond to the solenoid valve assembly 3, the outlet of the valve E and the outlet of the valve F are connected with the inner chamber 19 of the integrated valve, and the coaxial lines in the inner chamber 3 are oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com