Single-drum chimney preventing flue inlet smoke from colliding

A flue and single-tube technology, applied in the field of chimneys, can solve the problems of flue gas falling down and affecting the surrounding environment of the chimney, and achieve the effect of eliminating the cause of flue gas generation, convenient inspection and cleaning, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

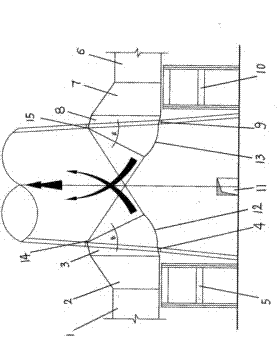

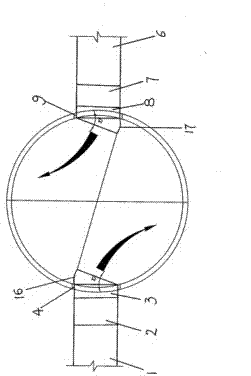

[0010] A single-tube chimney that prevents flue gas from colliding at the entrance of the flue, comprising a horizontally symmetrical left flue entrance 4 and a right flue entrance 8 of the single-tube chimney, which are on the left side of the left flue entrance 4 of the single-tube chimney A left flue support 5 is provided, and a left flue pipe 1 and a left flue expansion pipe 2 connected together are arranged on the left flue support 5, and a right chimney is arranged on the right outer side of the right flue entrance 8 of the single-tube chimney. Road support 10, the right flue pipe 6 and the right flue expansion pipe 7 that are connected together are arranged on the right flue support 10, and the left changing elbow 3 is arranged in the left flue entrance 4 of the single-tube chimney. The left end of the changing elbow 3 is connected with the left flue expansion pipe 2, and the left turning elbow 3 is bent and changed in an upward and forward direction, and a left turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com