Ejector pin type integrated circuit testing fixture

A technology for integrated circuits and test fixtures, applied in the field of fixtures, can solve problems such as the influence of test results and the generation of static electricity on the chip, and achieve the effects of uniform force, large use range and consistent use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

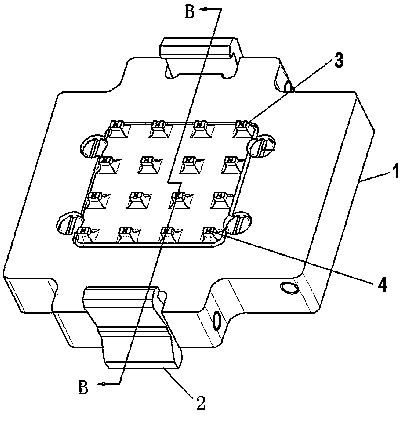

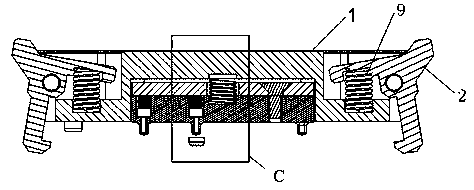

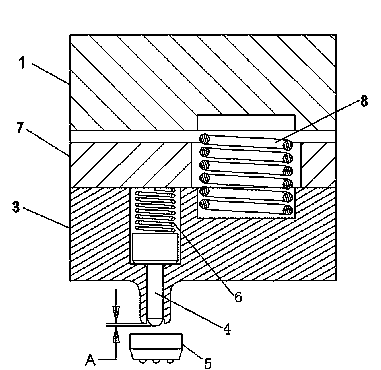

[0037] Figure 1~Figure 4 As described above, a thimble-type integrated circuit test fixture is composed of the following components: a cover body 1, a hook 2, a pressure plate 3, a thimble 4, a first spring 6, a cover plate 7, a second spring 8 and a hook spring 9.

[0038] Grab hook 2 is installed on cover main body 1 both sides, by grab hook spring 9 and locating pin, grab can open and close freely, and grab is used for connecting jig cover and jig base.

[0039] The thimble 4 is vertically embedded in the needle cavity of the pressure plate 3, the first spring 6, the cover plate 7, the pressure plate 3 and the thimble 4 are fastened by screw fasteners to form a thimble mechanism, and the thimble mechanism is installed in the inner cavity of the cover main body 1.

[0040] The thimble 4 is stepped, the first spring 6 is arranged between the cover plate 7 and the thimble 4, the thimble 4 is fixed in the pressure plate 3 under the spring force of the first spring 6, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com