A primary mirror floating support mechanism with a positioning film

A technology of floating support and thin film, applied in installation, optics, instruments, etc., can solve the problems of primary mirror deformation, reduced surface shape accuracy, and large difference in expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

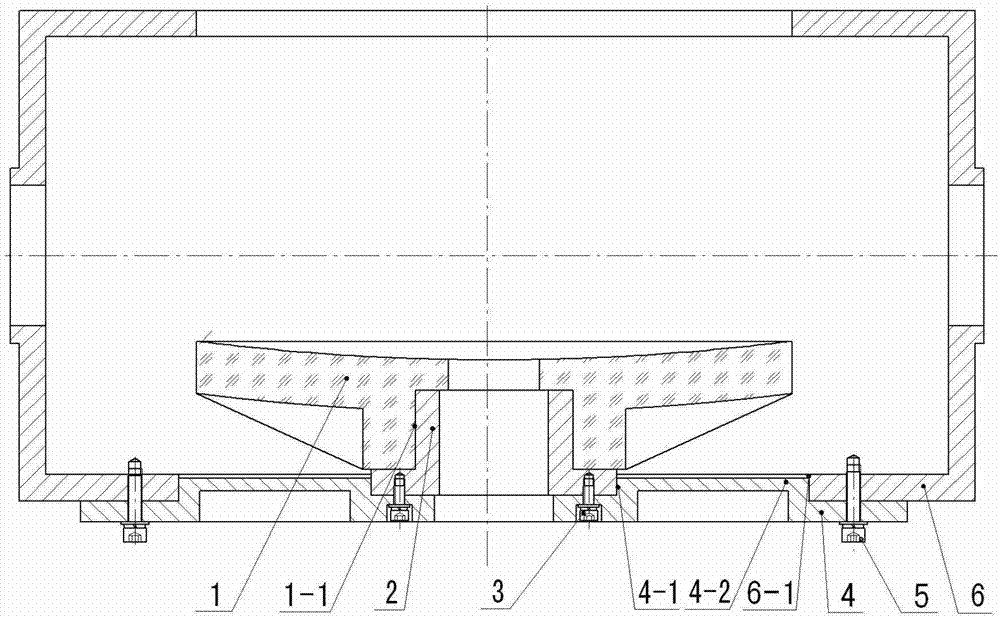

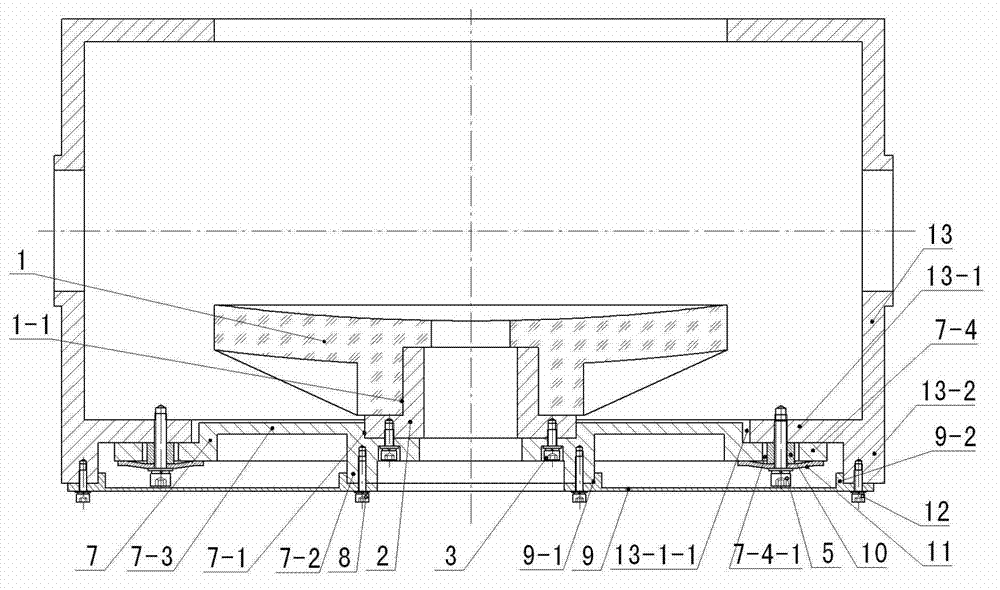

[0027] The material of the mandrel 2 and the bottom plate 7 is Invar, and the expansion coefficient of Invar is 0.1×10 -6 / °C, the primary mirror is made of glass-ceramics, and the expansion coefficient is 0.05×10 -6 / °C, the material of the cross 13 is 16Mn. The materials of positioning film 9 and Belleville spring 11 are 65Mn. The material of the pin shaft 10 and the second screw 5 is No. 45 steel. Among them, the expansion coefficients of 16Mn, 65Mn and 45 steel are all 11×10 -6 / °C.

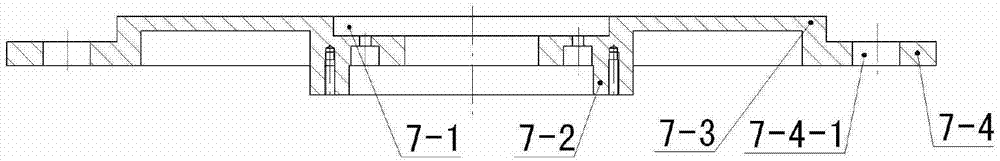

[0028] The gap between the positioning film annular boss 9-2 and the four-way round table 13-2 is 0.01mm-0.03mm. The matching gap between the annular boss 7-3 and the primary mirror mounting hole 13-1-1 is 1mm. The matching gap between pin shaft 10 and through hole 7-4-1 is 1mm. The pretightening pressure of the belleville spring 11 on the base plate 7 is 800N.

[0029] Because a kind of main mirror floating support mechanism with positioning film of the present invention is assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com