Spent fuel rod storage grillwork for nuclear power plant

A technology for storing grids and spent fuel, which is applied in the field of nuclear power equipment, can solve the problems of low section modulus, weak adsorption capacity, and module limitation of spent fuel rod storage grids, and achieves the effect of increasing the moment of inertia and increasing the storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] see Figure 1 to Figure 10 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

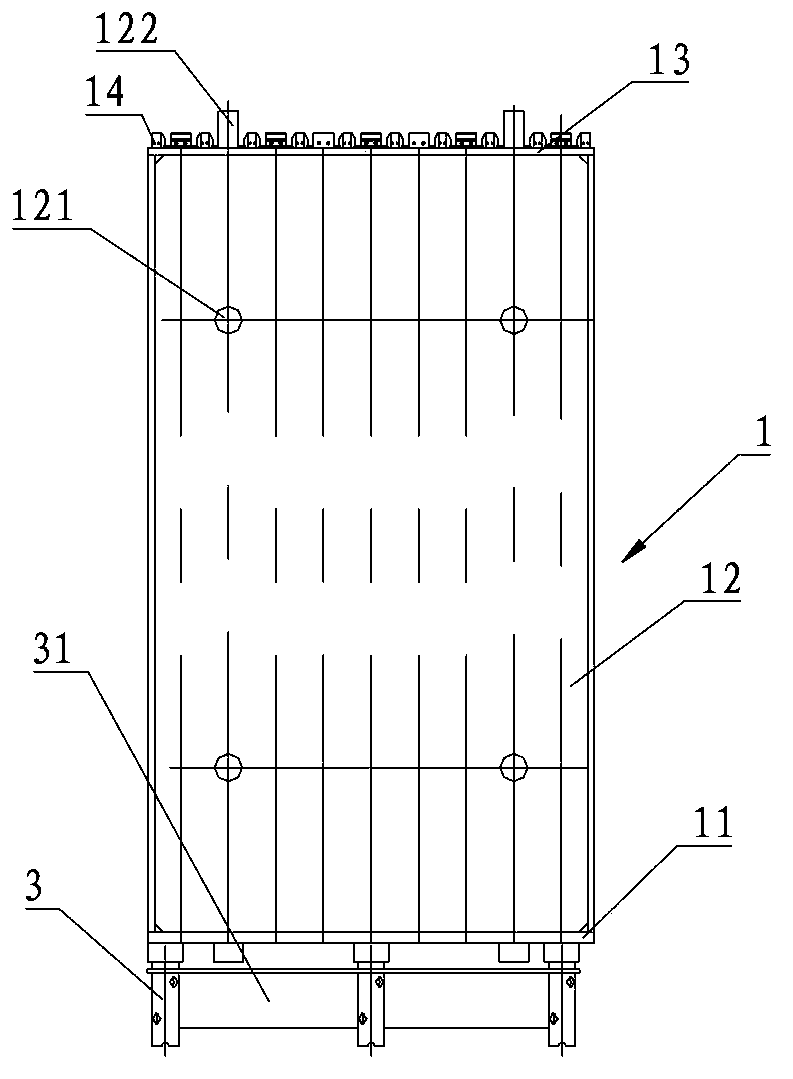

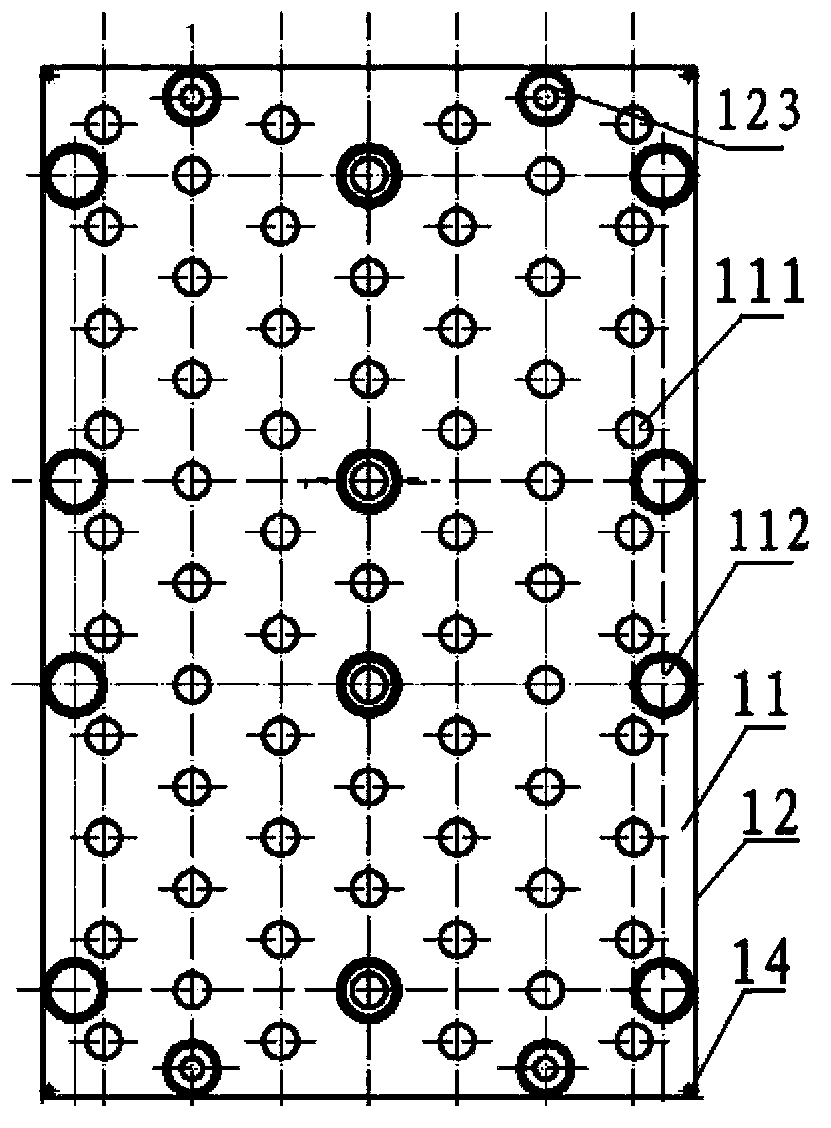

[0025] see Figure 1 to Figure 3 , a spent fuel rod storage grid for a nuclear power plant according to the present invention comprises a grid body 1 surrounded by a lower support plate 11 and a plurality of peripheral plates 12 , and inside the grid body 1 there are several The spent fuel rod storage chamber 2. The number of peripheral plates 12 in this embodiment is four.

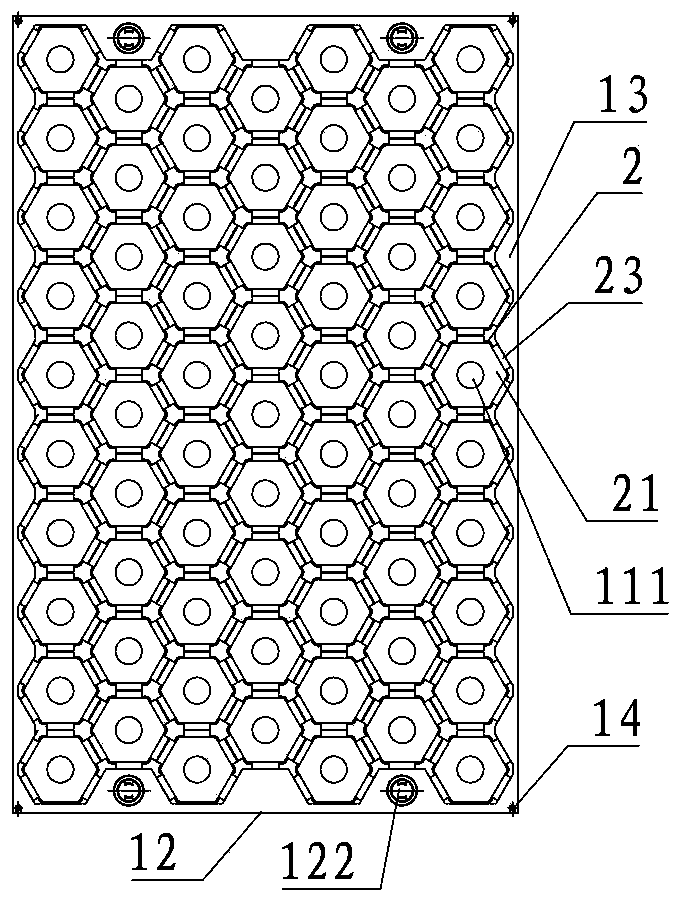

[0026] see Figure 4 to Figure 8 The spent fuel rod storage chamber 2 is a regular hexagonal prism steel pipe, and the center of the spent fuel rod storage chamber 2 is a spent fuel rod storage chamber 21 with openings at both ends. The spent fuel rod storage cavity 21 is coaxial with the spent fuel rod storage chamber 2 . The spent fuel rod sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com