Carbon brush component and carbon brush assembly with same

A carbon brush and component technology, applied in electrical components, current collectors, rotary current collectors, etc., can solve the problems of wasting human resources, reducing motor work efficiency, and unable to achieve continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

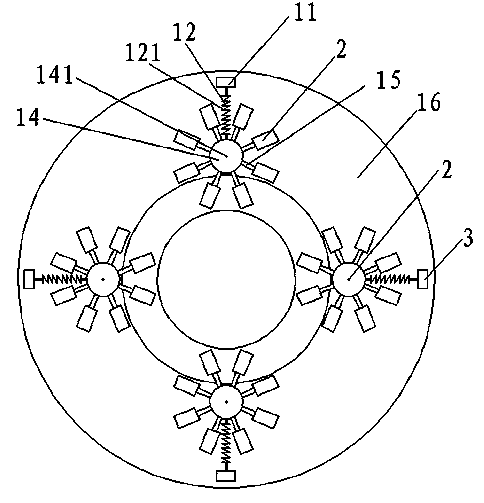

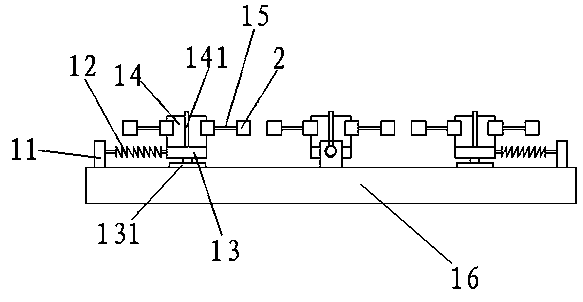

[0029] see image 3 and Figure 4 , the rest is the same as the first embodiment, the difference is that the first base 11 is also provided with a telescopic passage 121, and the elastic member 12 is disposed in the telescopic passage 121.

[0030] This ensures that the direction of the elastic force of the elastic member 12 is correct.

Embodiment 3

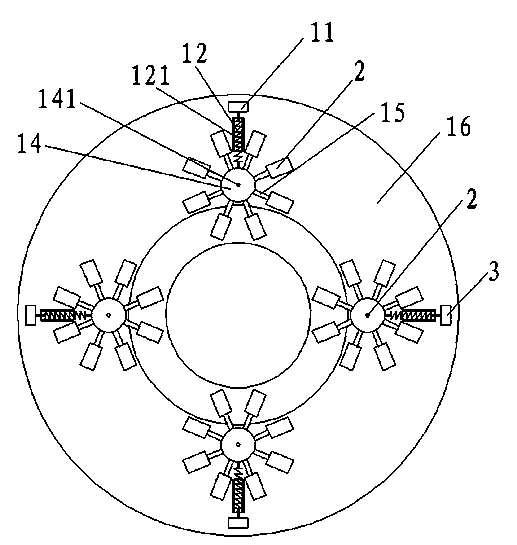

[0032] see Figure 5 and Figure 6 , as shown in the legend therein, the rest is the same as the first embodiment, the difference is that the rotating shaft 141 is also connected with the servo motor 17, the second base 13 is also connected with the servo cylinder 18, and the piston rod of the servo cylinder 18 It is connected to the second base 13 and the expansion and contraction direction is the same as that of the elastic member 12; the servo motor 17 and the servo cylinder 18 are electrically connected to an external controller.

[0033] When the carbon brush 2 is worn out, the external controller controls the servo cylinder 18 to make the second base 13 retreat along the sliding guide member 131, and at the same time controls the servo motor 17 to drive the rotating shaft 141 to rotate, so that the third base 14 rotates along the rotating shaft 141, so that The other carbon brushes 2 rotate to the position where they are in contact with the commutator, thereby achieving...

Embodiment 4

[0035] The rest is the same as that of Embodiment 3, except that a sensor is arranged on the fourth base, and the sensor senses the position of the connecting rod and transmits the signal to the external controller; the external controller controls the connection of the servo motor and servo cylinder.

[0036] When the sensor senses that the connecting rod reaches a certain position, it indicates that the carbon brush has almost worn out, and the sensor sends a control signal to the external controller, which can realize the automation of brush replacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com