Drainage body unit, drainage body system and shaft element

A technology of drainage ditch and components, which is applied in the field of filler drainage ditch unit, can solve the problems of large space and cost, and achieve the effect of increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

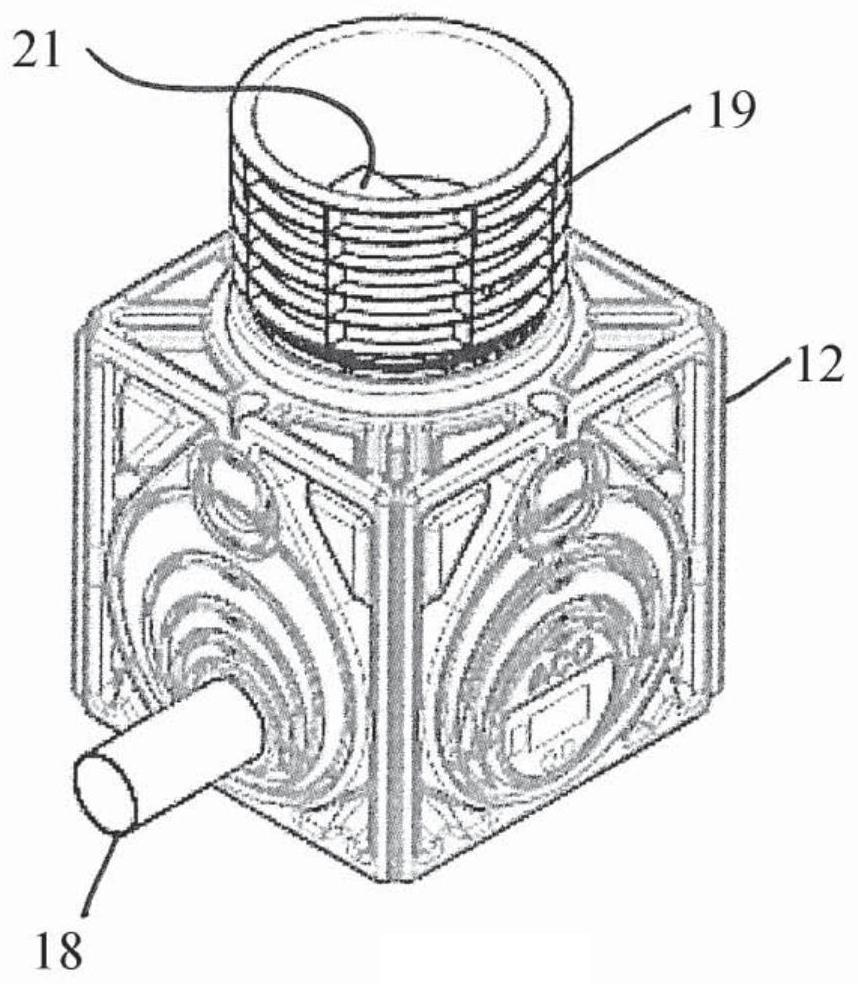

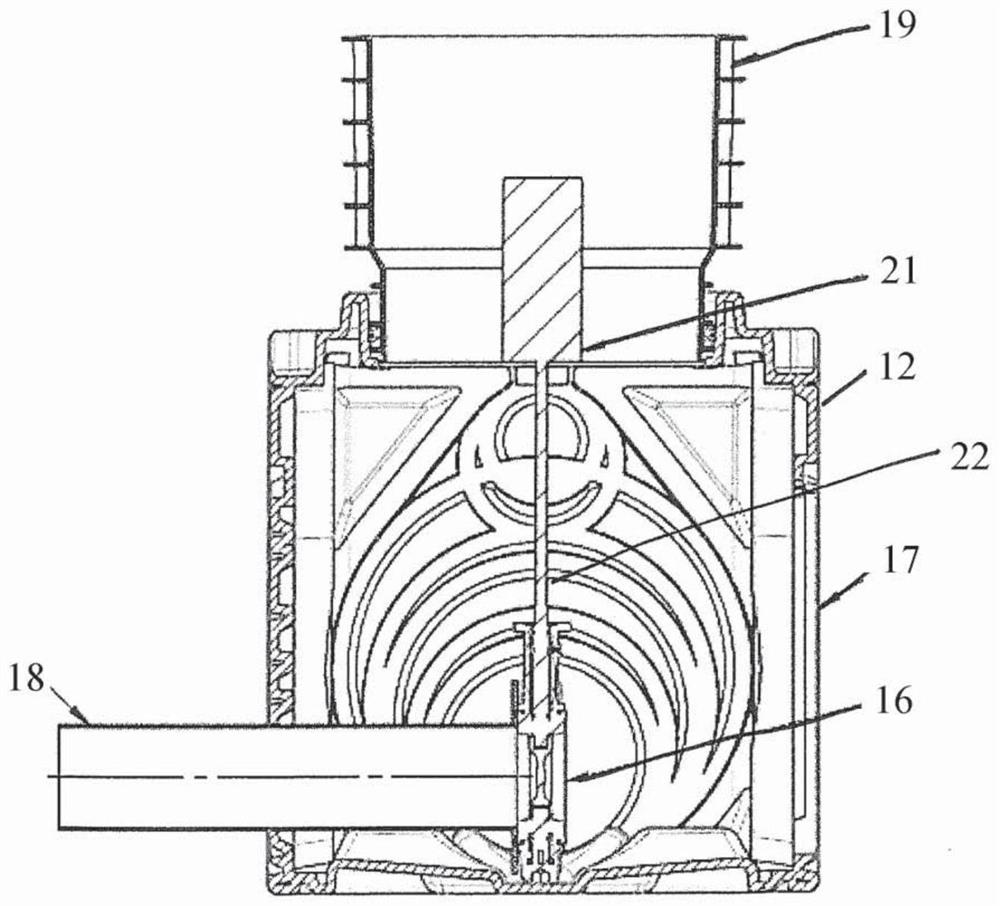

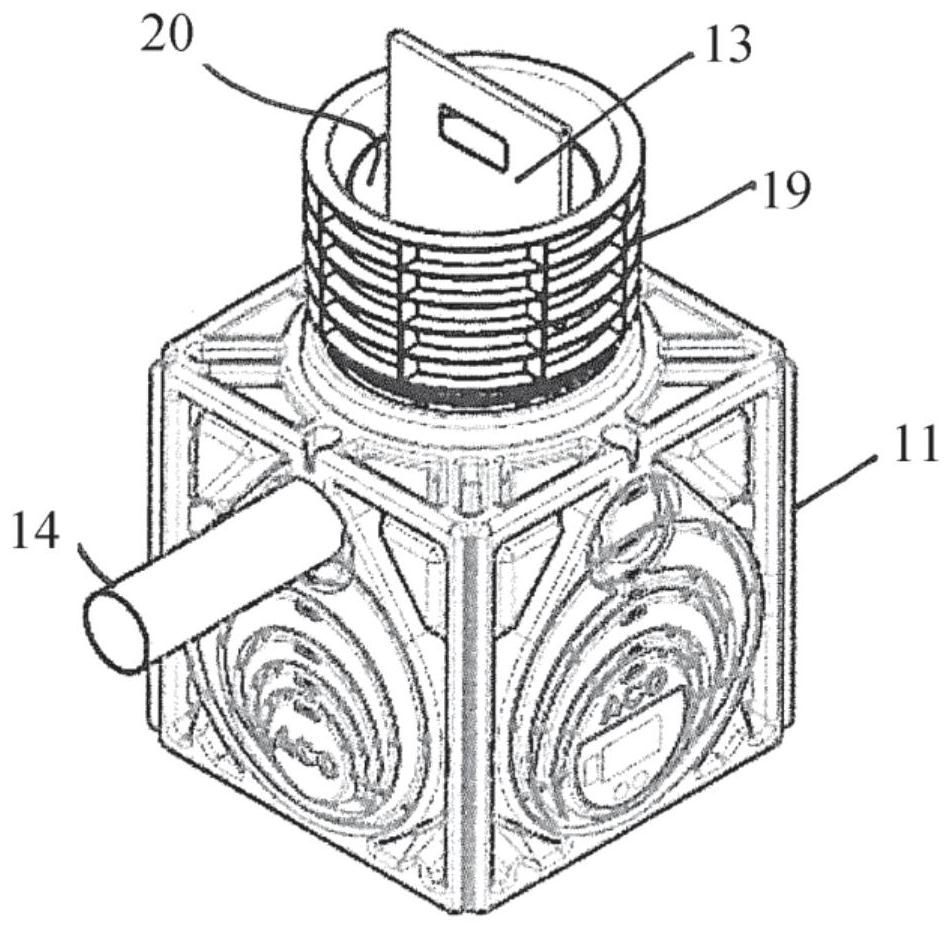

[0038] Figures 1 to 4 Shown are first and second hoistway elements 11, 12, which in accordance with Figure 5 , 6The fill gutter unit is integrated with the fill gutter element 10. The hoistway elements 11 , 12 are combined with a filler gutter unit and are disclosed and claimed individually, ie per se.

[0039] exist Figure 5 , 6 The fill gutter unit shown in can be used, for example, for rainwater retention, storage of rainwater or in combination with a fill gutter system as a fire water storage. Other applications are possible.

[0040] The fill gutter system consists of individual fill gutter elements which are sealed eg by PE film tapes or other means. Filler gutter elements are filled in use with a filler, such as gravel.

[0041] Fill gutter units as in Figure 5 , 6 As shown in , it consists of three parts, namely a first shaft element 11 with a cleaning element 13 , a second shaft element 12 with a throttle element 16 and a filler gutter element 10 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com