Grip jacket and grip for cutting tool

A handle and sheath technology, which is applied in the field of handle sheaths and cutting tool handles, can solve the problems of complex molding operations, complex mold relationships, labor and time, and achieve good anti-slip effects, uniform hand feeling, and raw material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

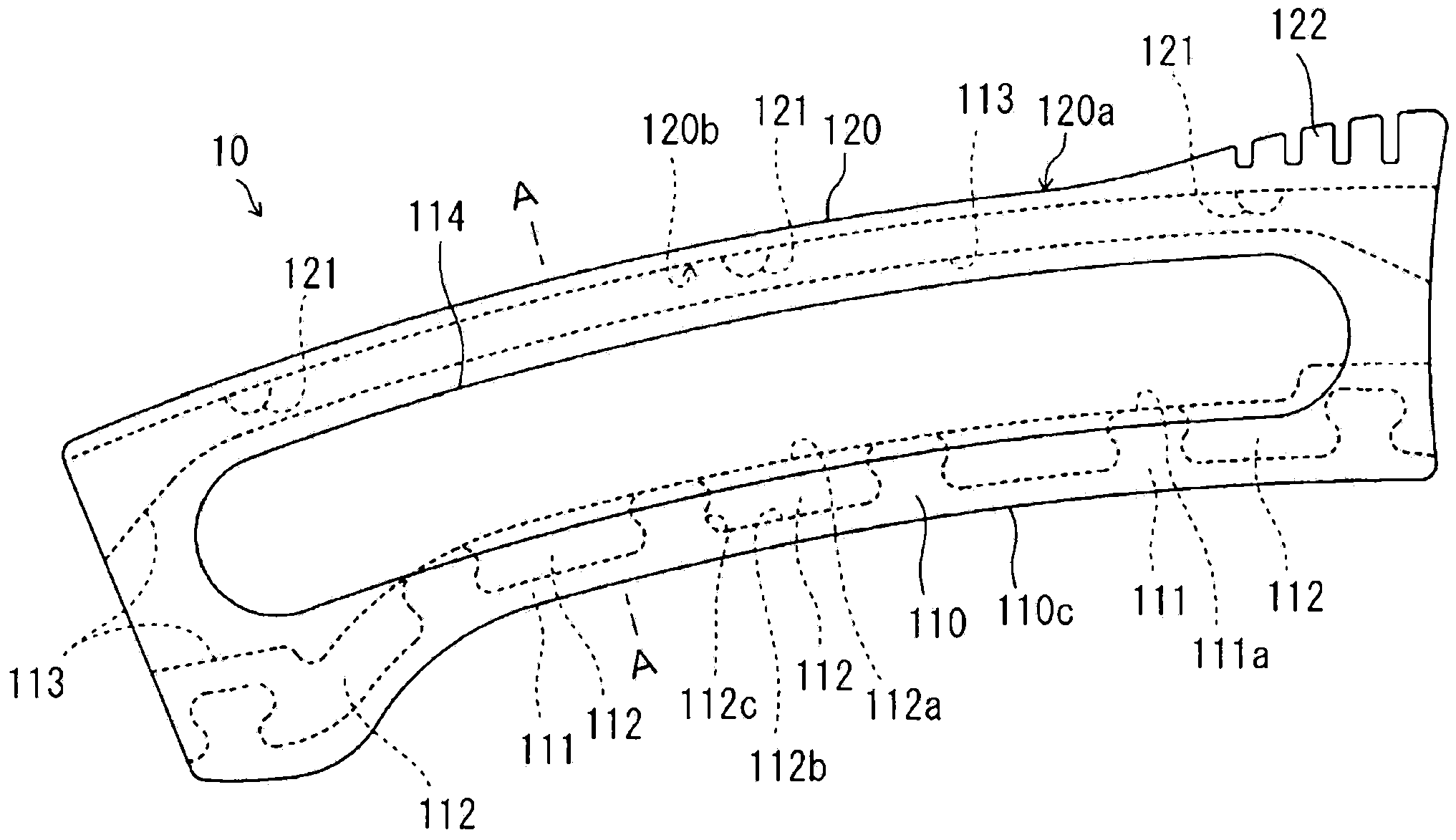

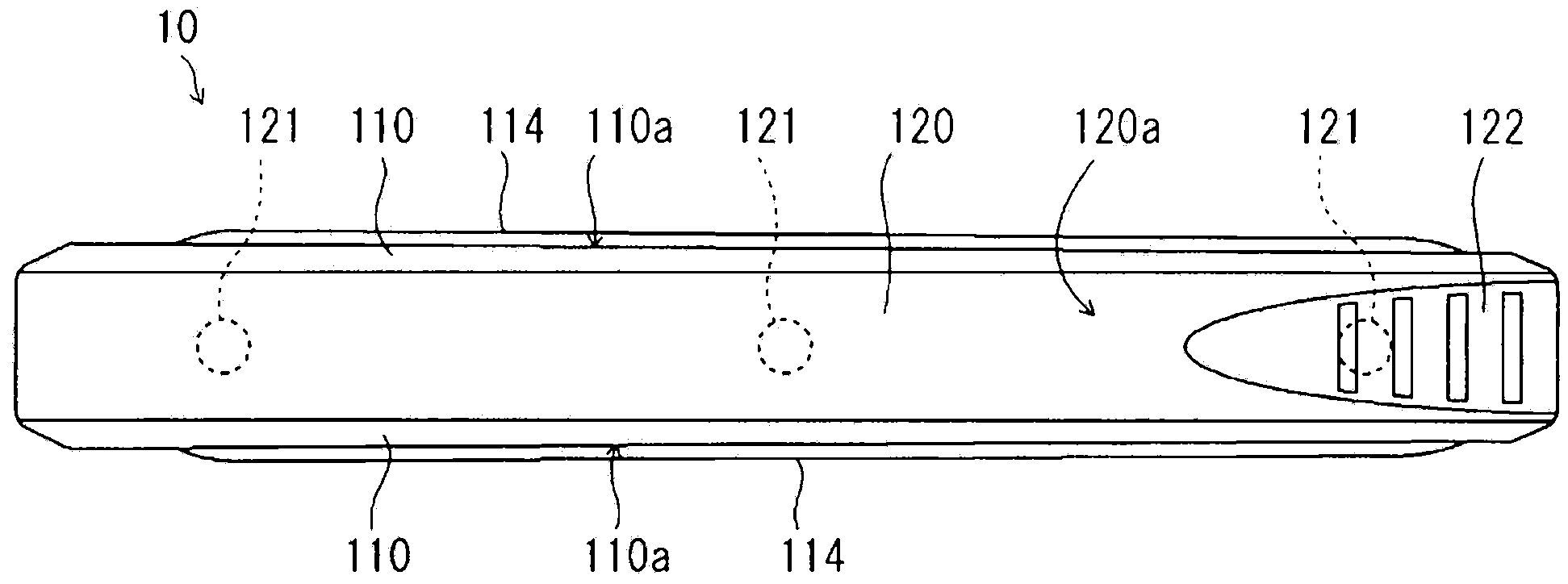

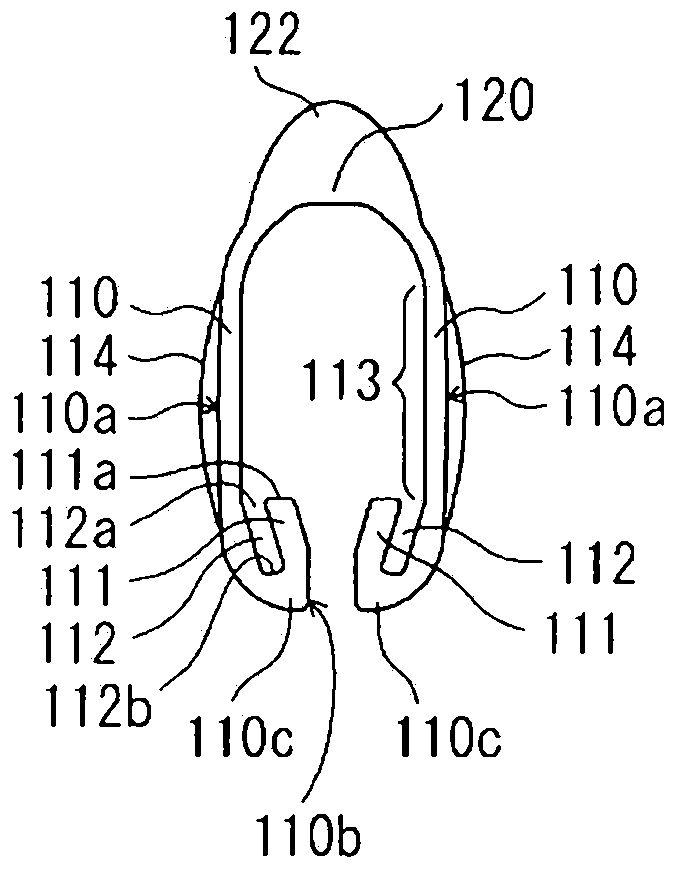

[0072] A handle cover and a handle for a cutting tool using the handle cover according to an embodiment of the present invention will be described with reference to the following drawings.

[0073] pass Figure 6 ~ Figure 10 The handle body 2 shown has a handle body 20 covering Figure 1 to Figure 5 The handle sheath 10 is shown, thereby completing the Figure 11 to Figure 15 The shown cutting tool uses a handle 1 .

[0074] The handle 1 for cutting tools of the present invention is actually described as a handle for a saw. In addition, the handle cover 10 has actually been described as a handle cover for a saw.

[0075] The handle cover 10 is made of an elastic body such as elastic rubber or elastic synthetic resin. That is, as an elastic body, it has at least shape deformability and shape restoration ability. When the handle sheath 10 is covered on the handle body 20, it is properly stretched and adjusted. closely match.

[0076] The handle sheath 10 has a size corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com