Method for producing seat composite part with 3D effect and related seat

A production method and a technology of composite parts, which are applied in the field of realization of skin cover composite parts, can solve the problems of limiting the style effect of composite parts, consuming liners, and expensive composite parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

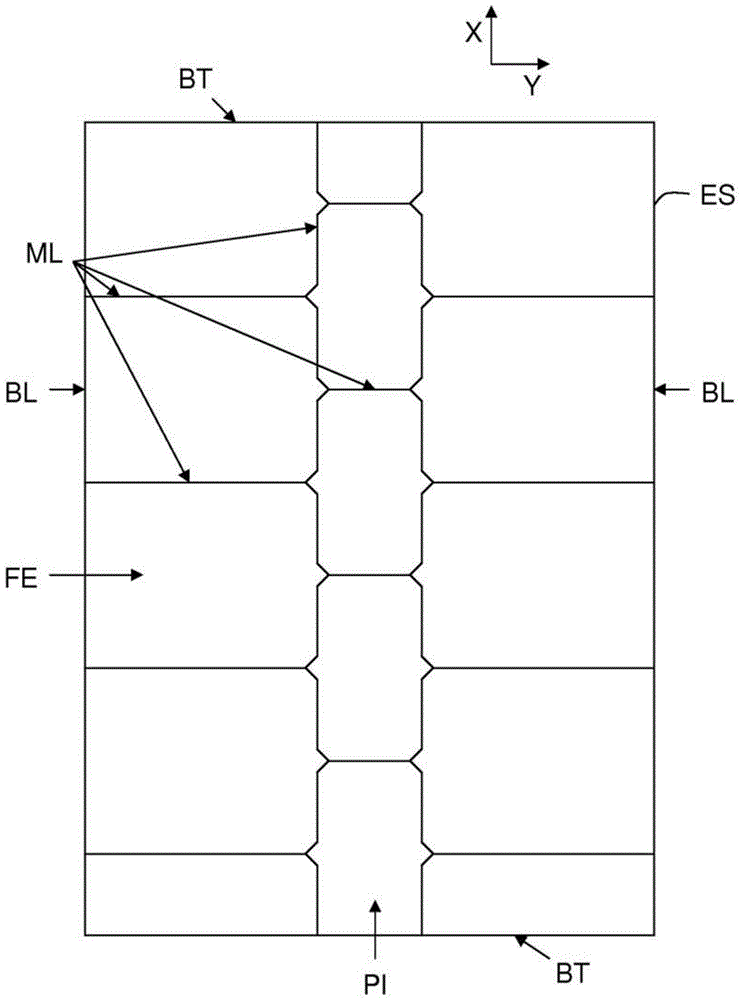

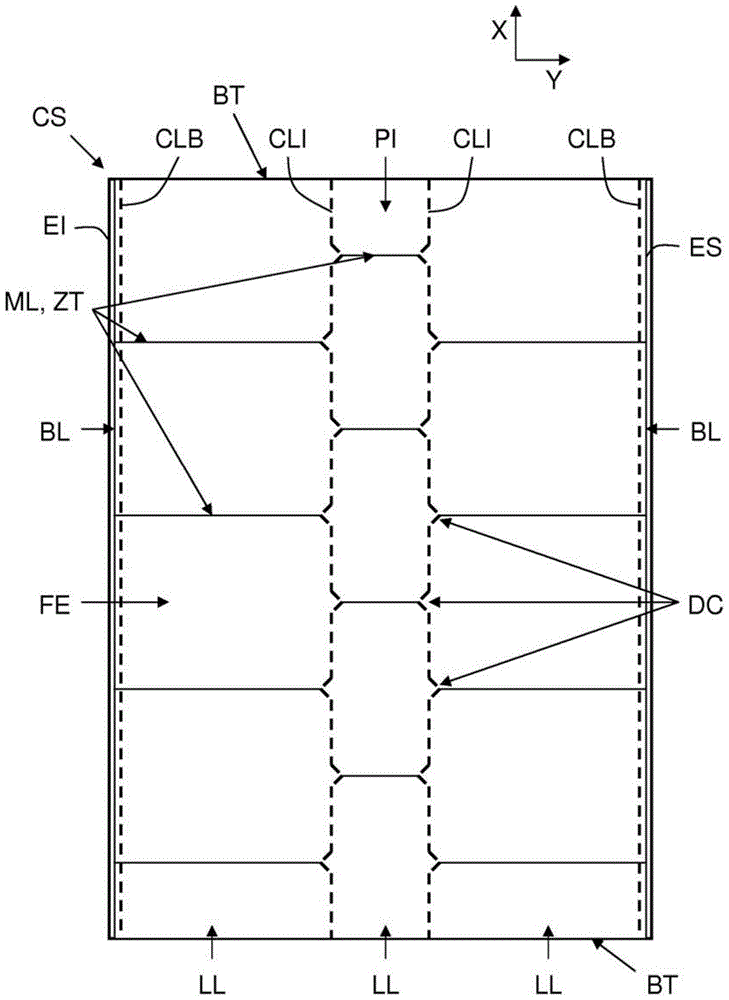

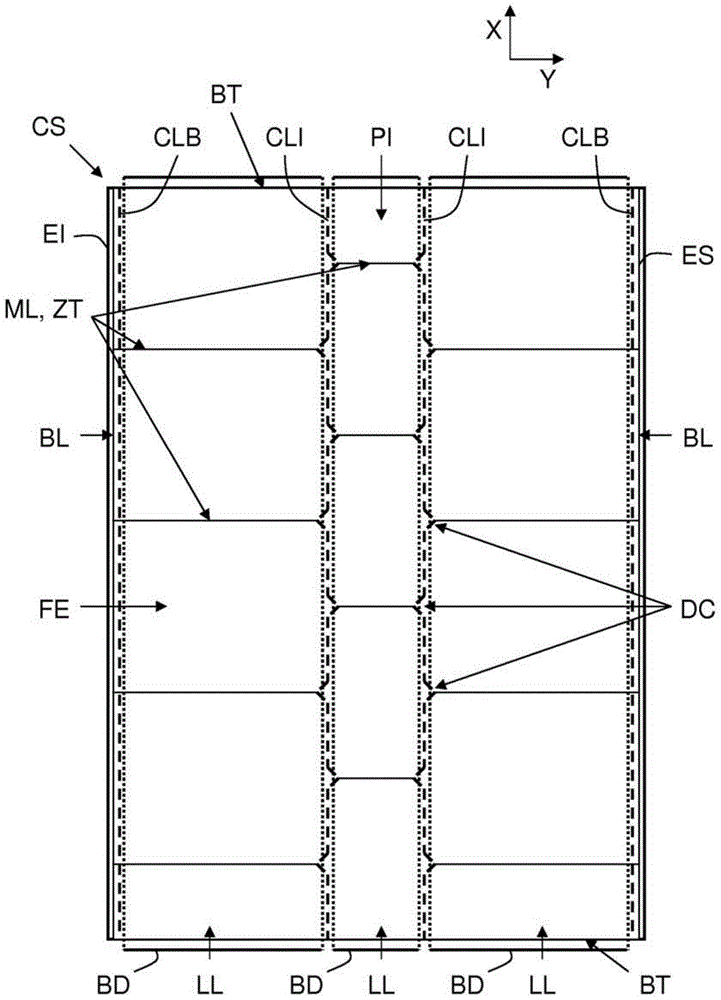

[0038] The drawings can be used not only to supplement the invention, but also to define it, if necessary.

[0039] It is an object of the present invention to provide a method for allowing realization of a seat composite CS comprising animations for constituting part of the leather cover of a seat back or of a seat seat.

[0040] In what follows, as a non-limiting example, it is conceivable that the seat composite CS is used to form part of the leather cover of the backrest of a motor vehicle seat. However, the invention is not limited to this type of application. The invention actually relates to any skin cover (possibly of the full row type) that is an integral part of the seat back or seat seat, regardless of the system in which the invention is installed (vehicle or building) .

[0041] Furthermore, in the following, as a non-limiting example, the use of the seat composite CS for constituting the front central part of the leather cover of the seat back of a motor vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com