Automatic production line of tea leaves

An automatic production line and automatic technology, applied in the field of tea, can solve the problems of not being able to meet the needs of the development of tea product production, not being able to form automated or continuous production, and not being able to realize standardized production, so as to save labor, ensure freshness, and prevent corruption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

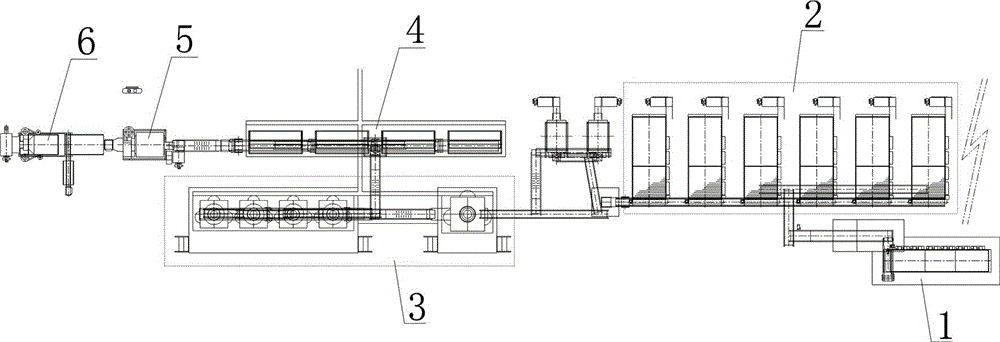

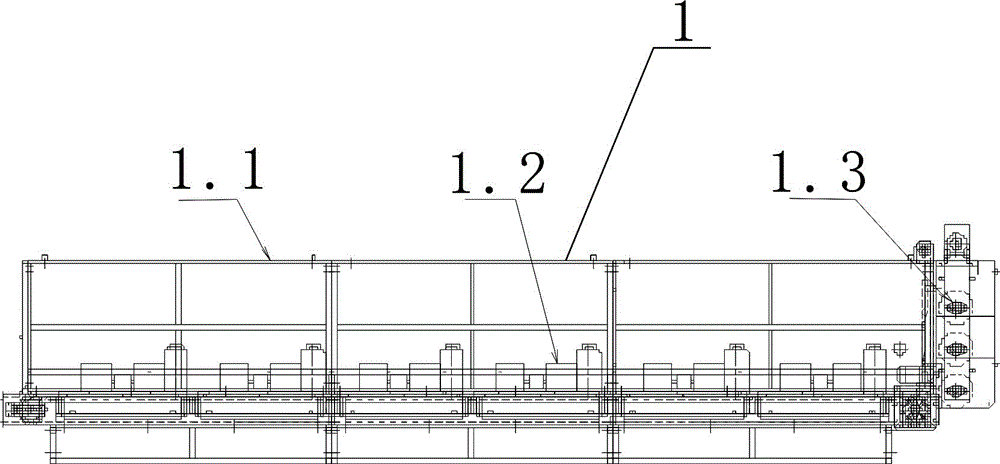

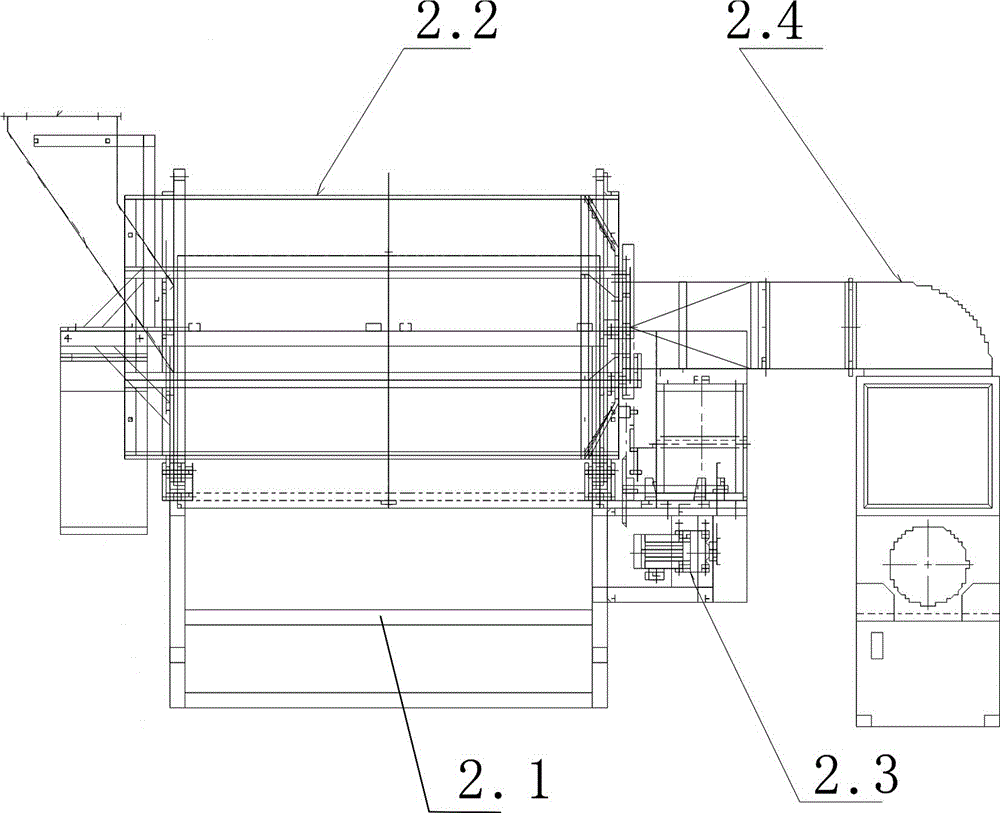

[0022] Such as figure 1 Shown, a kind of automatic tea production line, comprises fresh leaf automatic storage device 1, withering device 2, automatic kneading device 3, fermenting device 4, tight strip re-drying device 5, drying device 6, described fresh leaf automatic storage device 1 is connected Withering device 2, withering device 2 is connected with automatic kneading device 3, automatic kneading device 3 is connected with fermentation device 4, fermentation device 4 is connected with tight strip re-drying device 5, and tight strip re-drying device 5 is connected with drying device 6.

[0023] Working principle: The fresh leaf automatic storage device 1 is equipped with a blower fan and a humidifier, and artificially blows air and humidifies the fresh leaves. The withering device 2 is composed of a rotary withering device and a rotary withering device. The gas hot air generator converts the gas flame into warm air, which is transported from the bottom to the main body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com