A friction welding preheating mechanism and preheating method with static electricity removal function

A friction welding and static elimination technology, applied in the field of friction welding, can solve the problems of breakdown of electronic components and the welding quality needs to be improved, and achieve the effects of short heating time, high energy consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments are only for illustration and do not constitute any limitation to the present invention.

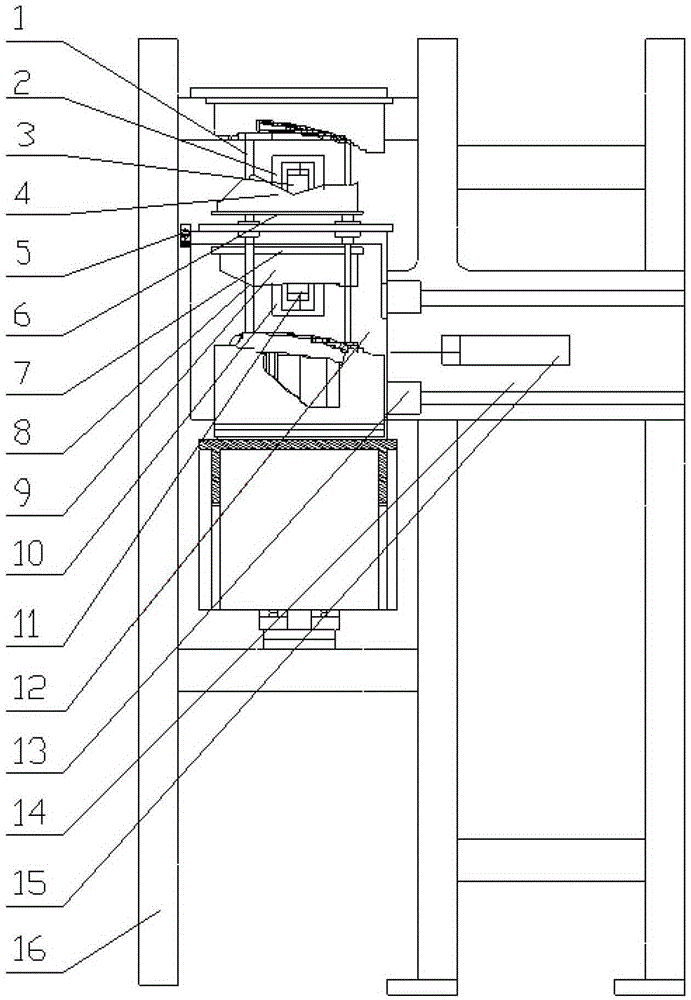

[0033] figure 1 It is a structural schematic diagram of the present invention. The friction welding preheating mechanism with the function of eliminating static electricity shown in the figure includes: a friction welding support, and upper and lower sides parallel to each other that can move in a manner opposite or opposite to each other are arranged beside the friction welding support. , The lower mounting plate, the upper preheating mold is set on the upper mounting plate, the lower preheating mold is set under the lower mounting plate, 4 guide shafts are vertically penetrated upward on the upper mounting plate, and the lower mounting plate is vertically downward There are 4 guide shafts running through, and an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com