High-voltage power capacitor insulator transfer tool

A high-voltage power and capacitor technology, applied in the field of high-voltage power capacitor porcelain bottle transfer tools, can solve the problems of easy collision of porcelain bottles, damage, occupying a large workshop area, etc., and achieve the effect of reducing workshop area, improving safety performance, and saving use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

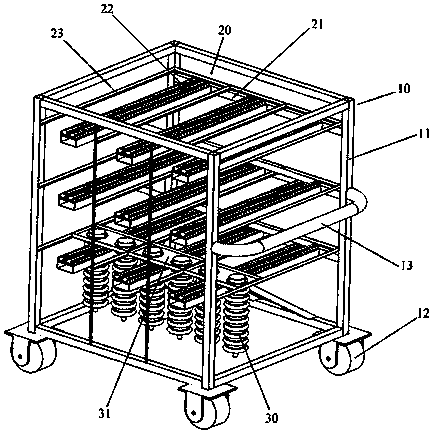

[0022] The invention provides a high-voltage power capacitor porcelain bottle transfer tool, such as figure 1 Shown is a preferred embodiment of the present invention, a high-voltage power capacitor porcelain bottle transfer tool, including a vehicle frame 10, three groups of sliding mechanisms 20 are fixed on the vehicle frame 10, and the porcelain bottle 30 is hung on the sliding mechanism 20 and can slide along the Bodies slide. details as follows:

[0023] The vehicle frame 10 includes a vehicle body frame 11 with a cubic structure, four rollers 12 installed at four corners below the vehicle body frame 11 , and a cart handle 13 arranged on one side of the vehicle body frame 11 .

[0024] Three groups of sliding mechanisms 20 are vertically and parallelly arranged on the vehicle frame 10 in three upper and lower layers. The porcelain bottle 30 is hung on the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com