Method for determining optimal welding time of PE electric melt pipe fitting

A technology of welding time and electric fusion pipe fittings, which is applied in the field of determining the best welding time of PE electric fusion pipe fittings, can solve the problems of waste of materials, complex theory, and increased development costs of enterprises, and achieve the effect of saving raw materials and reducing development investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

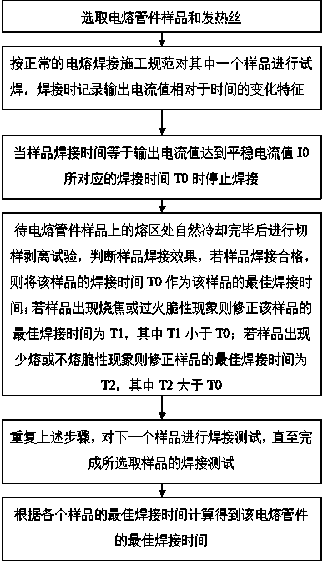

[0026] Such as figure 1 As shown, a method for determining the best welding time of PE electrofusion pipe fittings, including:

[0027] S101. Select an electrofusion pipe fitting sample and a heating wire; wherein, the selected electrofusion pipe fitting samples have the same or similar resistance, which can ensure that the obtained optimal welding time is more accurate. Then select the material and specification of the heating wire according to the size, wall thickness and length of the melting zone of the selected electrofusion fittings.

[0028] S102. Perform test welding on one of the samples according to the normal electric fusion welding construction specification, and record the change characteristics of the output current value relative to time during welding.

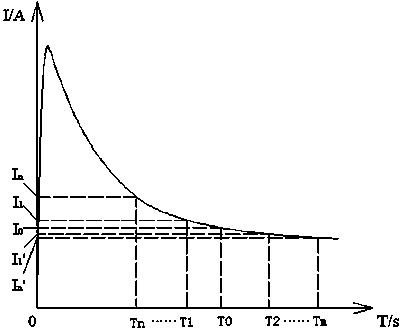

[0029] S103. Stop welding when the sample welding time is equal to the welding time T0 corresponding to the output current value reaching the steady current value I0; usually when the welding starts, the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com