Isolating agent used for producing redispersible emulsion powder and preparation method for the isolating agent

A technology of redispersing latex powder and release agent, which is applied in the field of building materials, can solve the problems of latex particles not being uniform and small, affecting the use effect, adhesion and agglomeration, etc., achieving good separation effect, improving production efficiency and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

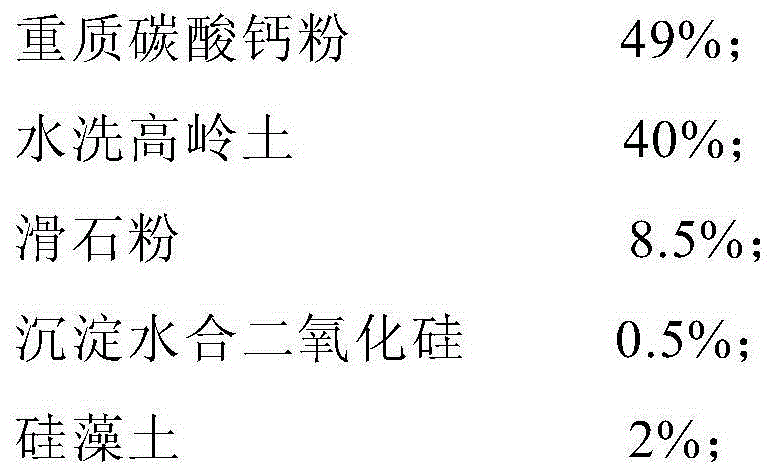

Embodiment 1

[0038] Put 49 kg of heavy calcium carbonate powder, 40 kg of washed kaolin, 0.5 kg of precipitated hydrated silicon dioxide, 8.5 kg of talcum powder, and 2 kg of diatomaceous earth into a mixer, and after mixing evenly, a kind of isolation compound of the present invention is obtained. finished product.

Embodiment 2

[0040] Put 37.5 kg of heavy calcium carbonate powder, 60 kg of washed kaolin, 0.5 kg of precipitated hydrated silica, 1 kg of talcum powder, and 1 kg of diatomaceous earth into a mixer, and after mixing evenly, a kind of isolation compound of the present invention is obtained. finished product.

Embodiment 3

[0042] Preparation of release agent

[0043] Put 65 kg of heavy calcium carbonate powder, 30 kg of washed kaolin, 2 kg of precipitated hydrated silicon dioxide, 2 kg of talcum powder, and 1 kg of diatomaceous earth into a mixer, and after mixing evenly, a kind of isolation compound of the present invention is obtained. finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com