Self-righting abrasion-proof hollow sucker rod

A technology of hollow sucker rods and sucker rods, which is applied in the direction of drill pipes, drilling equipment, earthwork drilling and production, etc. It can solve problems such as damaged and broken sucker rods, rising water content in oil wells, and affecting oil well production, so as to reduce oil recovery costs , improve the service life, good righting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

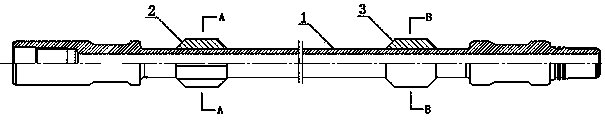

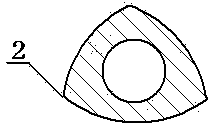

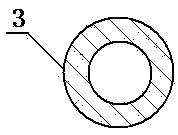

[0010] refer to figure 1 — image 3 , a self-supporting formal wear-resistant hollow sucker rod, comprising a hollow sucker rod body 1, a centralizer 2 and a wear-resistant device 3 are respectively provided on the inner side of the pipe rod joint at both ends of the sucker rod body 1, and the centralizer 2 The distance between the centralizer 2 and the anti-wear device 3 is greater than 2 meters; both the centralizer 2 and the anti-wear device 3 can rotate freely on the sucker rod body 1 . Wherein, the centralizer 2 is a three-arc structure composed of nylon fibers or carbon fibers. The wear preventer 3 is an annular structure composed of nylon fibers or carbon fibers.

[0011] During operation, the annular centralizer 2 on the sucker rod body 1 and the three-arc-shaped wear preventer 3 can freely rotate on the sucker rod body 1 without slipping in the axial direction. During the up and down movement of the sucker rod, the centralizer 2 automatically straightens, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com