Metal mine downhole microseismic monitoring system

A microseismic monitoring and mining technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., to achieve the effects of preventing underground accidents, being easy to master, and optimizing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

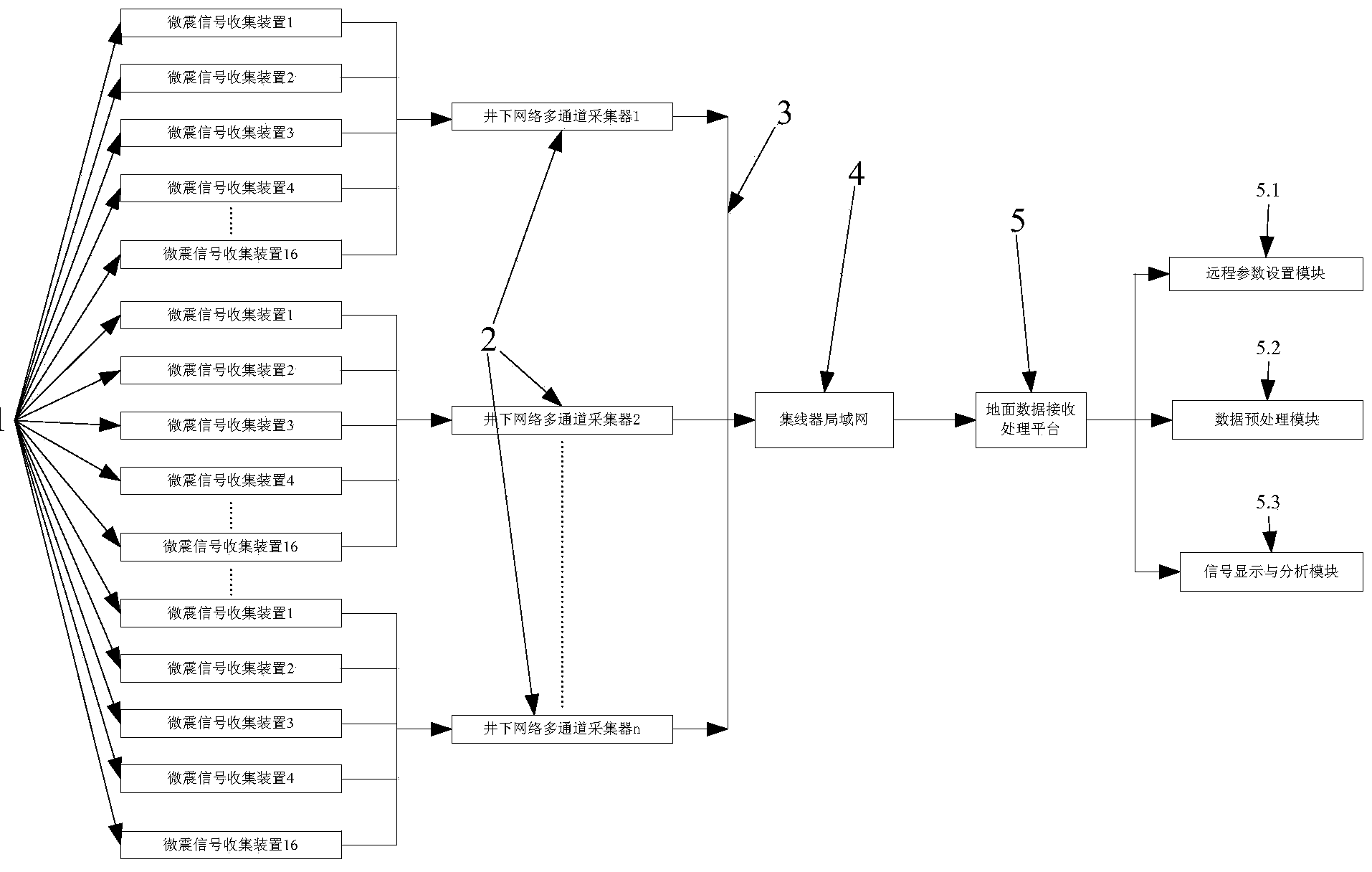

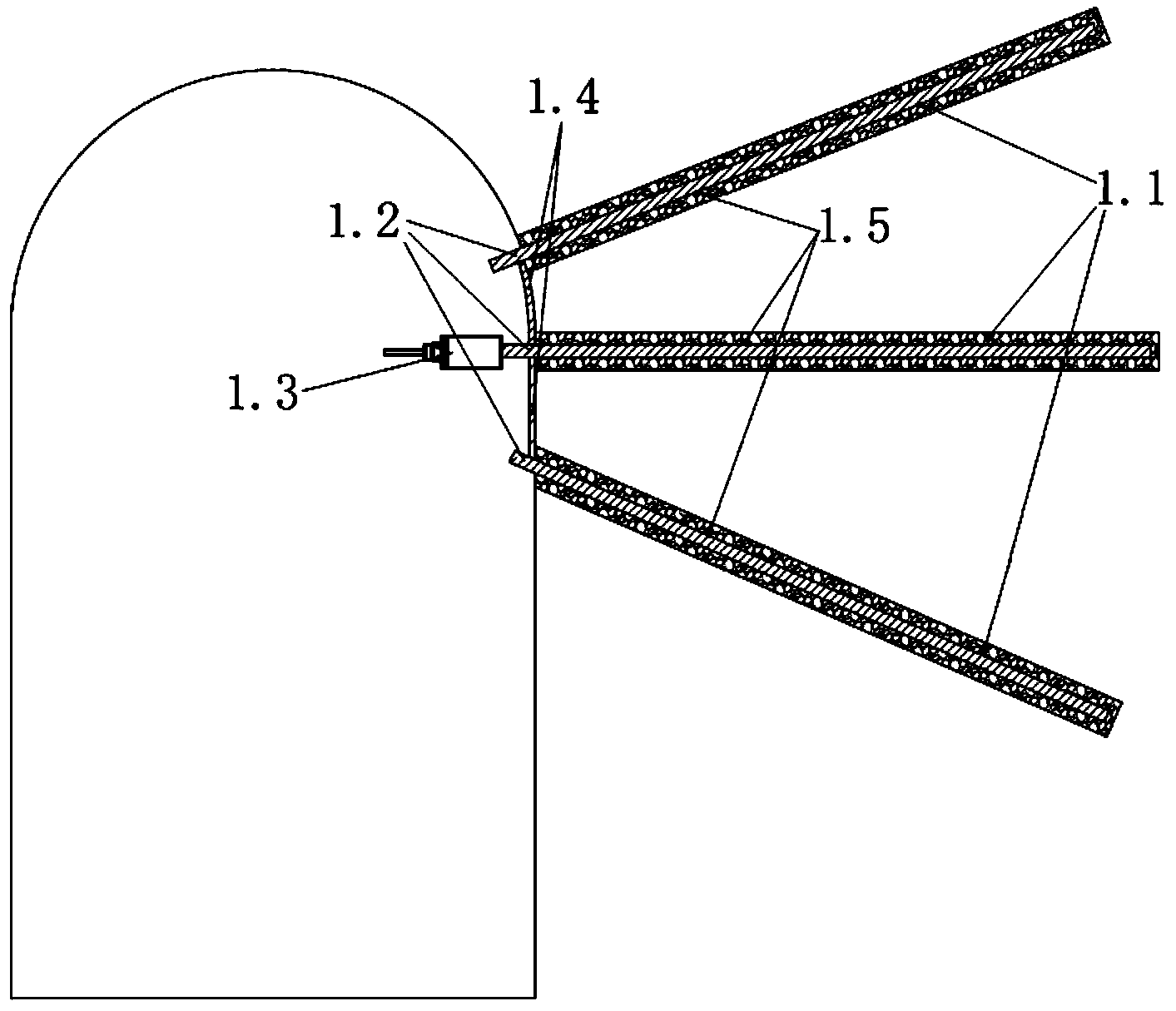

[0022] see figure 1 , The metal mine underground microseismic monitoring system of the present invention includes a microseismic signal collection device 1, an underground network multi-channel collector 2, a transmission local area network 3, a hub local area network 4 and a ground data receiving and processing platform 5.

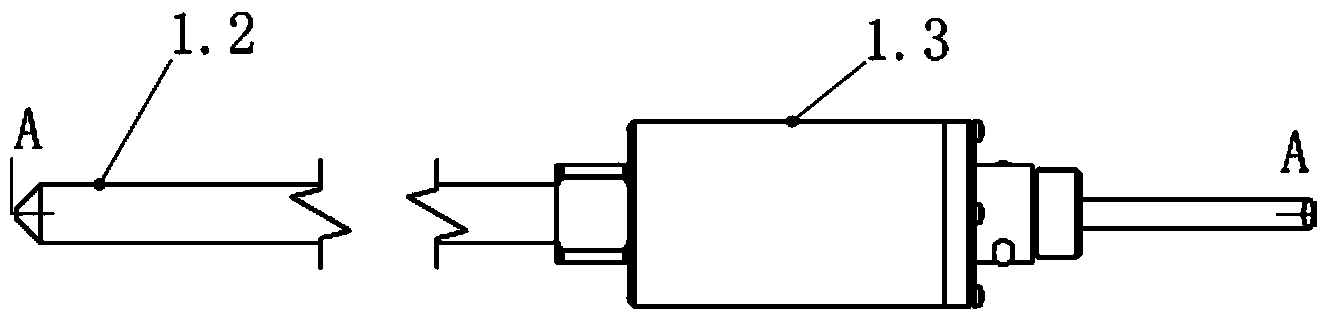

[0023] There is at least one downhole network multi-channel collector 2, and in this embodiment, there are three downhole network multi-channel collectors 2, all of which are set in the roadway of the underground section to be monitored. The downhole network multi-channel collector 2 includes 16 differential input channels for analog signal acquisition, each differential input channel is connected to a microseismic signal collection device 1 respectively, and each microseismic signal collection device 1 is fixedly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com