The working method of the intelligent code stomping device for hollow blocks and bricks

A working method, the technology of intelligent code, applied in the directions of transportation and packaging, stacking of objects, de-stacking of objects, etc., can solve the problem of easy damage of the positioner, relieve the pressure in the cavity, widely applicable places, and prolong the life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

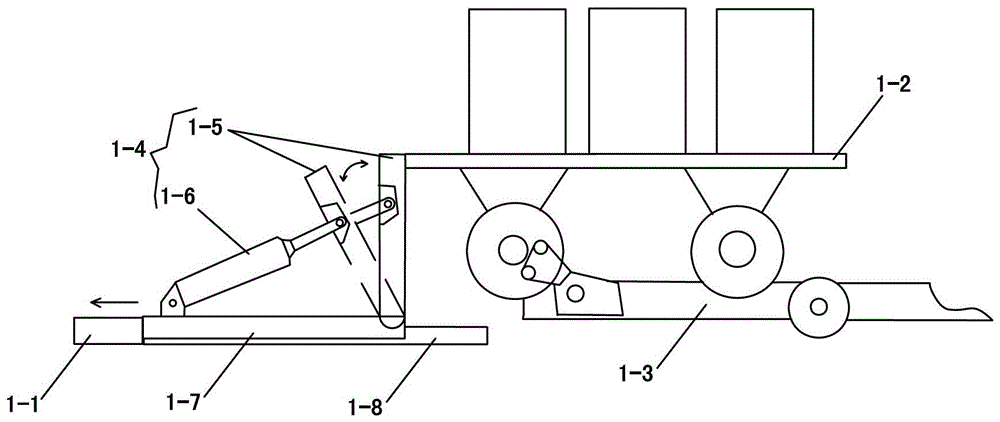

[0020] See figure 1 , a working method of an intelligent code stomping device for adobe code stamping, wherein the intelligent code stomping device includes: an automatic feeder 1-3 for hanging a steam curing car 1-2 to a code stomping area, The positioner 1-4 used to limit the steaming car 1-2 to the code stamping area, and the robot used to perform the code stamping operation on the steaming car 1-2 ( figure 1 not shown in ), the positioner includes: a support arm 1-5, one end of which is connected to a cylinder 1-6 on the left side of the support arm 1-5, and the cylinder 1-6 is used to prop up or lower the support arm ; The locator 1-4 is fixed on a slider 1-7, that is, the other end of the cylinder 1-6 and the bottom of the arm 1-5 are respectively connected to the left and right ends of the slider 1-7; This slider 1-7 is slidingly matched with a guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com