Excitation valve

A technology of excitation valve and spool, applied in the field of hydraulic control, can solve the problems of complex control system, insufficient flow rate, high output frequency of excitation valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

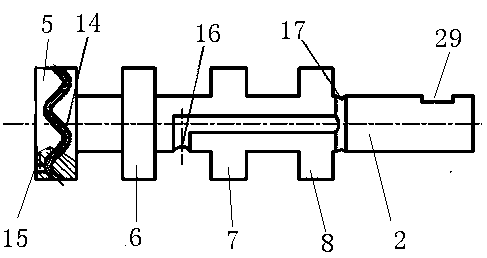

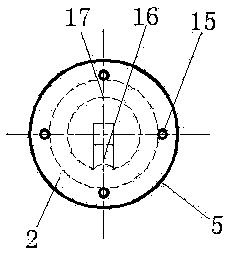

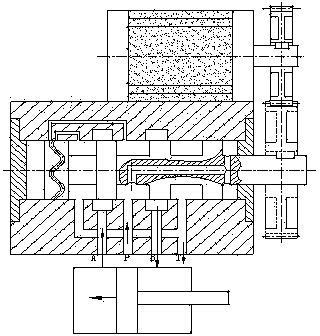

[0016] Embodiment 1: An excitation valve is composed of a valve body 1, a valve core 2, a left end cover 3, and a right end cover 4. The excitation valve is essentially a three-position four-way electrically driven reversing valve. The three bits are left, middle, and right. The four-way is the control port A25, the main oil inlet port 20, the control port B27, and the oil return port T23. The valve core 2 is provided with a throttling shoulder 5, a control shoulder A6, and a control shoulder B7 from left to right. , The high-pressure shoulder 8 protrudes from the opening on the right end cover 4, and the protruding end is provided with a keyway 29. Through the keyway 29, the torque is connected by the motor and the gear set, so that the spool 2 rotates, and then the axial reciprocating motion of the spool 2 is generated, and the oil inlet reversing of the control port A25 and the control port B27 is realized; the corresponding excitation valve The valve chamber is divided in...

Embodiment 2

[0017] Embodiment 2: A vibration-exciting valve, in which a wave-shaped groove 14 is provided on the peripheral surface of the throttling shoulder 5, specifically a sine wave with a wave number of 4, the groove is 2 mm deep, and 3 mm to ensure that the valve core 2 is in the neutral position When the opening is 0.11. The other structures of the valve are the same as in Embodiment 1, and the spool of the vibration valve is equipped with a flange and directly connected with a frequency conversion stepper motor. If the rotation frequency of the motor is set to 100Hz, then the output frequency of the excitation valve is 4×100=400 Hz.

Embodiment 3

[0018] Embodiment 3: A vibration-exciting valve, in which a wave-shaped groove 14 is formed on the peripheral surface of the throttling shoulder 5, specifically a sine wave with a wave number of 6, with a groove width of 3 mm and a groove depth of 3 mm to ensure that the valve core 2 is in the neutral position When the opening is 0.2. The working principle of the excitation valve is the same as that of the first two embodiments, except that the valve body and the valve core are manufactured by 3D printing technology. If the rotation frequency of the motor is set to 50Hz, the output frequency of the excitation valve is 6×50=300 Hz, because the groove width of the waveform groove is larger than that of the previous two embodiments, and the openings of the high-pressure hole and the low-pressure hole are also the same. Larger, the output flow of the excitation valve also becomes larger, that is, the output power becomes larger.

[0019] In a word, the present invention is diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com