Air-condition bidirectional throttle valve with three-time throttling and vibration damping function

A two-way throttling valve and air-conditioning technology, applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve the problems that the diaphragm cannot feel the temperature of the return gas in time, difficult to balance the cooling capacity, and the reduction of the circulation channel, etc., to achieve It is beneficial to work stability, overcomes the balance of refrigeration capacity, and reduces the effect of spring friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

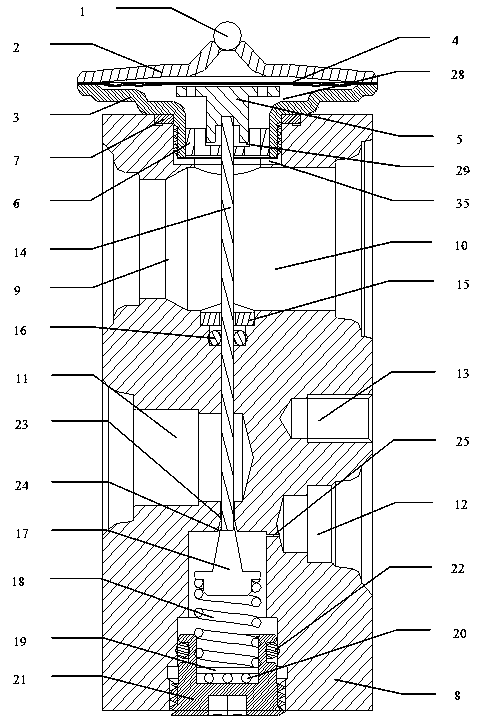

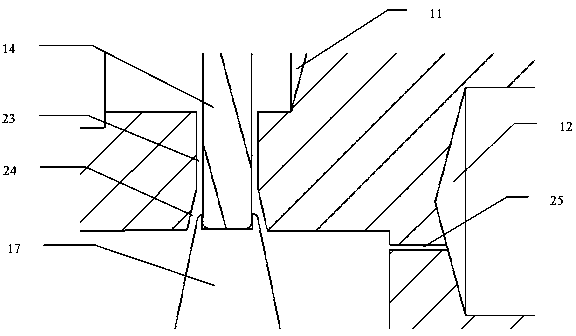

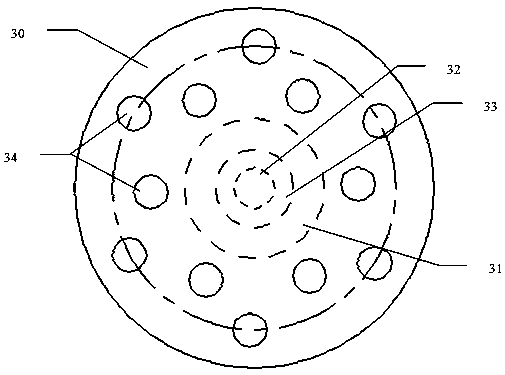

[0020] Such as figure 1 , Image 6 As shown, the sealing steel ball 1 is installed in the center hole of the upper membrane cover 2 at the top of the valve of the present invention, the diaphragm 4 is installed between the upper membrane cover 2 and the lower membrane cover 3, and the transmission block 5 is installed under the diaphragm 4, the transmission block 5 is connected to the lower membrane cover 3 by the positioning circular plate 6 of the transmission block, a first gap 28 is formed between the bottom surface of the large end 30 of the transmission block 5 and the shoulder of the lower membrane cover 3, and the bottom surface of the small end 31 of the transmission block 5 is positioned with the transmission block A second gap 29 is formed between the circular plates 6. The height of the second gap 29 must be smaller than the first gap 28. The lower bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com