Light-emitting element spot measurement machine

A technology of light-emitting element and spot measuring machine, which is applied in photometry, optical radiation measurement, measuring device, etc., can solve the problem that the light transmittance of the scattering angle carrier plate affects the efficiency of light receiving, the result of the light-emitting diode 21 is inaccurate, and cannot be used. Problems such as point measurement of the object to be measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

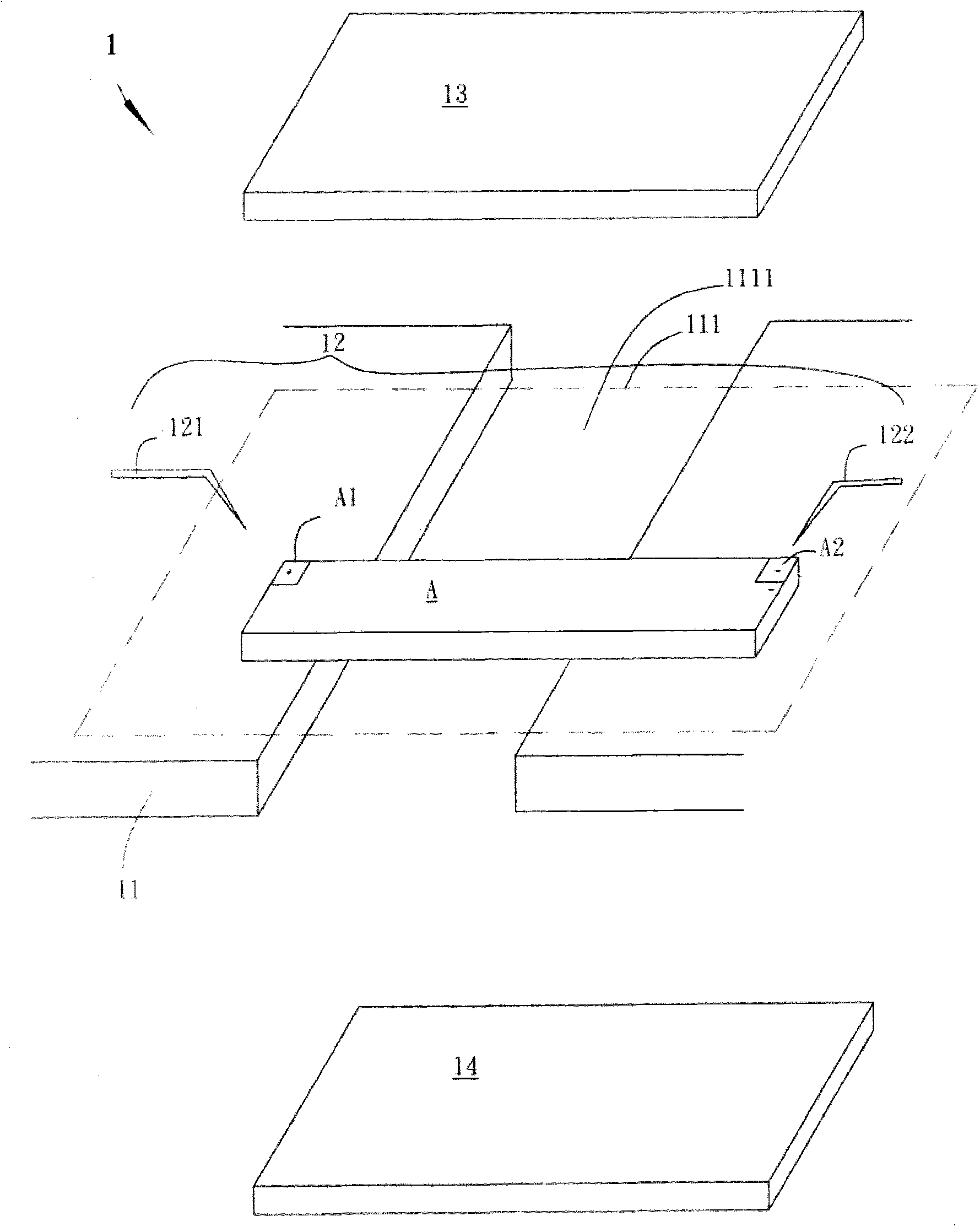

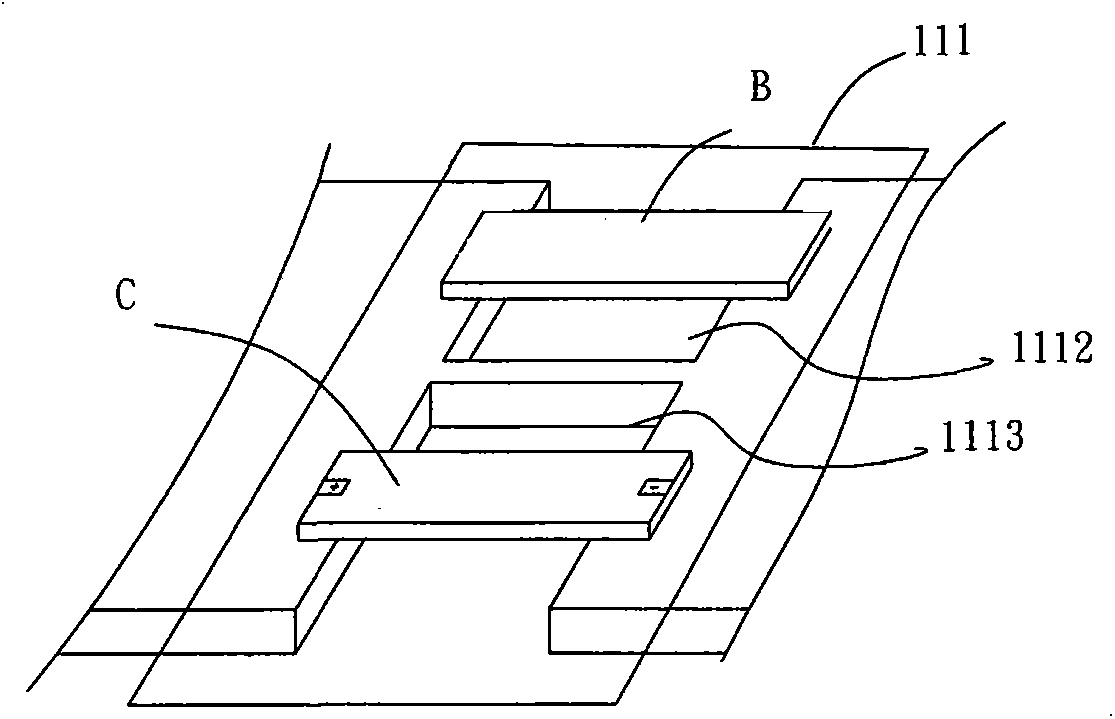

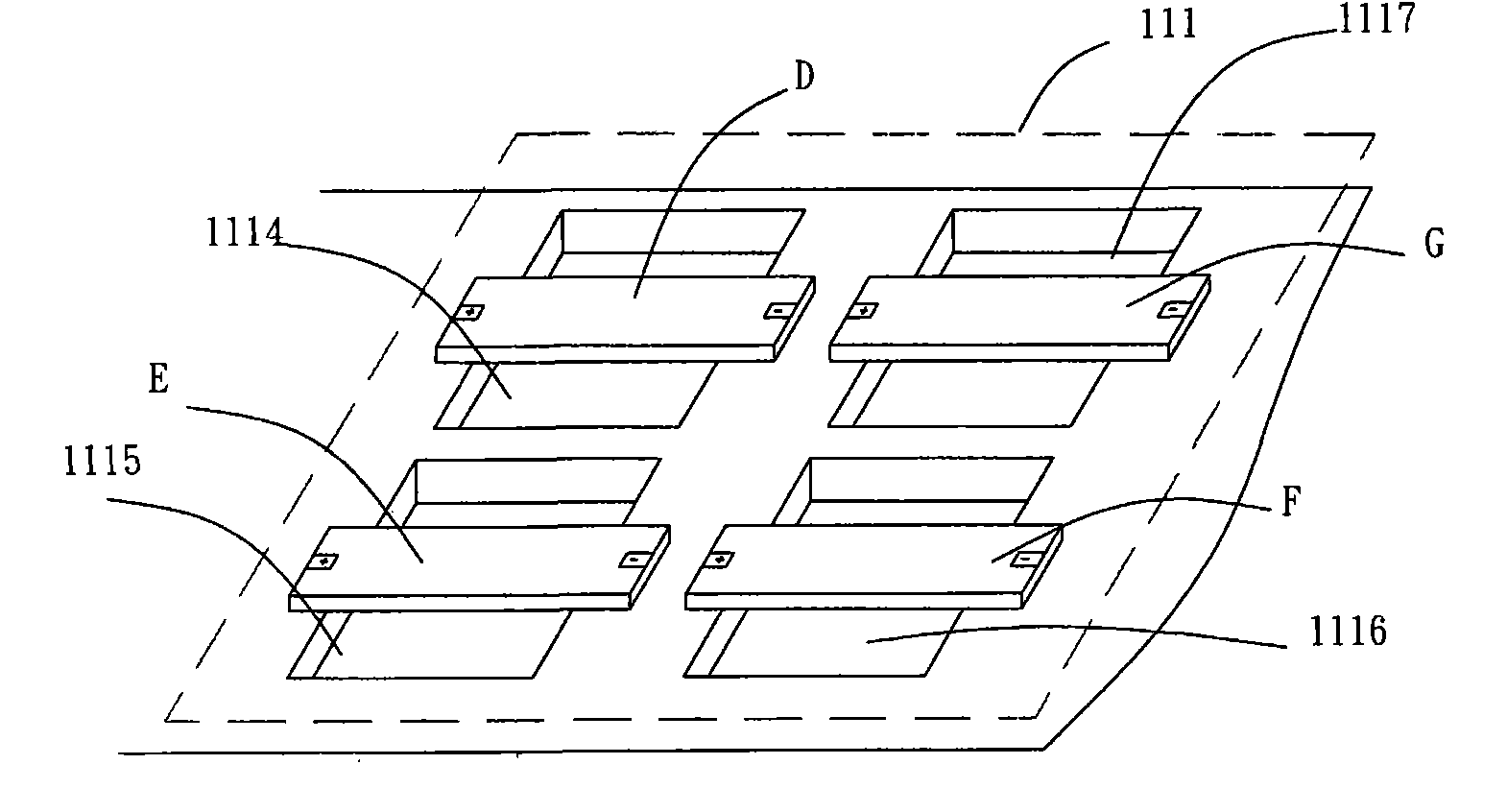

[0020] Please refer to figure 1 , is a three-dimensional schematic diagram of a first aspect of a first preferred embodiment of a spot testing machine for light-emitting elements of the present invention. Light-emitting element point test machine 1, through applying electricity to make a light-emitting element A turn on and emit light, and then collect optical data of the light-emitting element A, including: a carrying platform 11, with a carrying position 111 forming a spanning space 1111 , the straddling space 1111 of the carrying position 111 is used to hold at least one light-emitting element A; a set of probes 12 includes a first probe 121 and a second probe 122 for contacting a first probe of the light-emitting element A An electrode A1 and a second electrode A2, and provide the required electrical properties, so that the contacted light-emitting element A is turned on and emits light; a first light collection device 13 is correspondingly arranged above the carrying pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com