Integrated reagent needle device

A reagent needle and integrated technology, which is applied in the field of sampling devices, can solve problems such as stability and safety defects, differences in film production effects, and low throughput, so as to improve operation stability, improve processing effects, and reduce residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

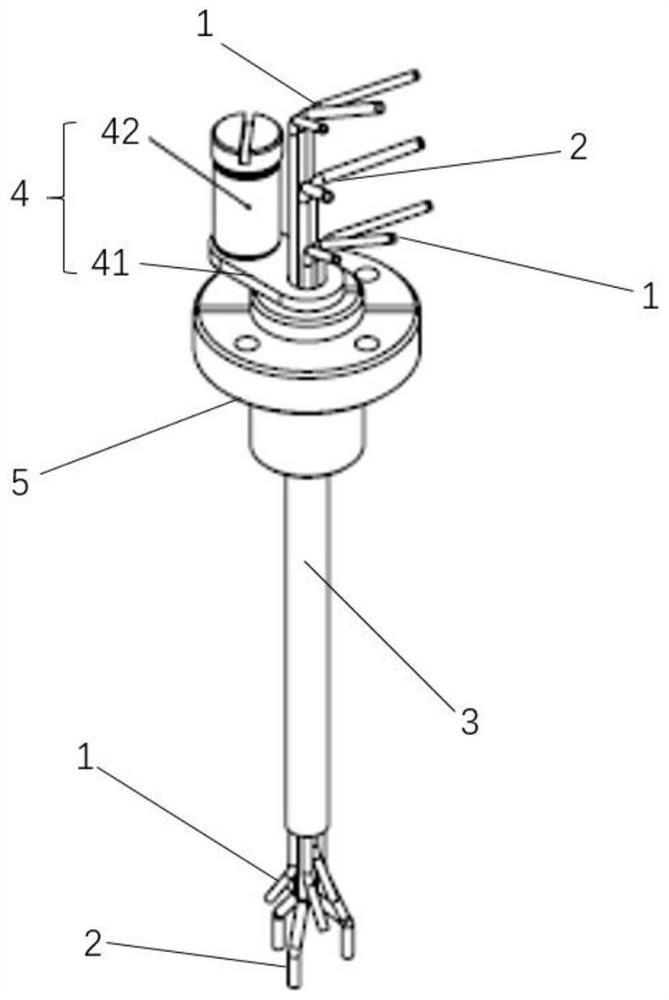

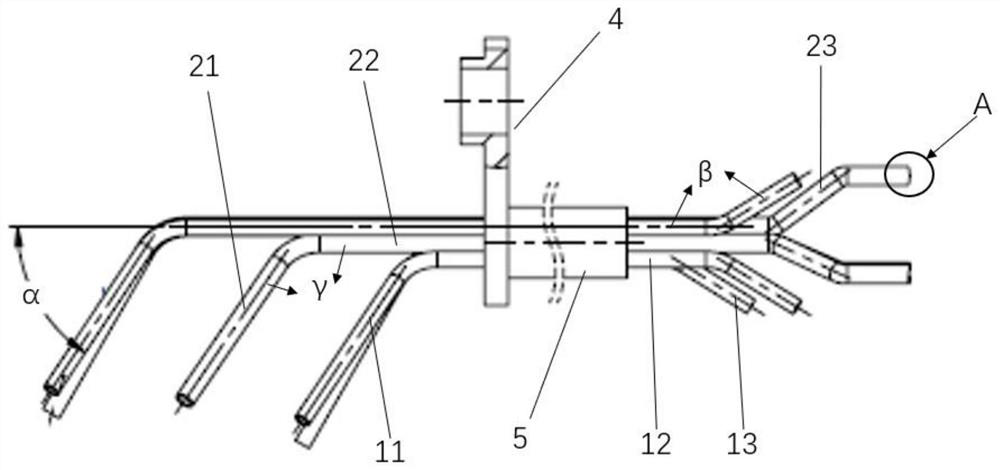

[0031] The invention provides an integrated reagent needle device, which includes a liquid injection needle 1 , a liquid suction needle 2 and a syringe 3 . The injection needle 1 is used for injecting reagents, including an injection section 11 into which the reagent enters, a discharge section 13 for discharging the reagent onto the glass slide, and an intermediate section 12 connecting the injection section 11 and the discharge section 13 . Preferably, the injection section 11 , the middle section 12 and the discharge section 13 form the injection needle 1 through integral molding. The liquid suction needle 2 is used to discharge the reagent waste liquid after the experiment is completed, including a liquid discharge section 21 for waste liquid discharge, a suction section 23 for absorbing waste liquid, and a communication section 22 connecting the liquid discharge section 21 and the suction section 23 . Preferably, the liquid outlet section 21 , the communication section 22...

Embodiment 2

[0035] This embodiment 2 is formed on the basis of embodiment 1, through the optimized design of the liquid suction needle structure in the device, the treatment effect of the device on waste liquid is improved. specifically:

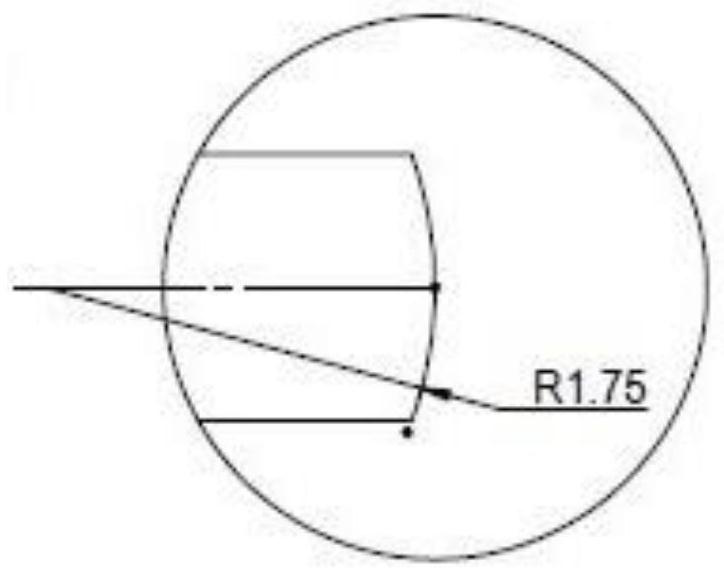

[0036] A plurality of liquid-absorbing needles 2 are integrally installed in the syringe 3, and the plurality of liquid-absorbing needles 2 can simultaneously absorb waste liquid, which not only improves the absorption efficiency of waste liquid, but also further reduces the residual amount of waste liquid. Preferably, the ports of the suction section 22 are arranged horizontally. Here, the horizontal arrangement means that the suction port can be in flush contact with the surface of the glass slide, so that the waste liquid on the slide can be better absorbed. Further, the ports of the suction sections 22 of the plurality of liquid suction needles 2 are distributed along the circumferential direction, preferably evenly distributed along the circumfere...

Embodiment 3

[0040] Embodiment 3 is formed on the basis of Embodiment 1 or Embodiment 2. By adding a buffer device and a connecting device, the operation stability and installation convenience of the integrated cleaning device are improved. specifically:

[0041] A buffer device 4 is also provided in the integrated cleaning device, and the buffer device 4 includes a buffer plate 41 and a spring 42 . The spring 42 is installed on one end of the buffer plate 41 , and the spring 42 is elastically deformed along the vertical direction, and the vertical direction is the axial direction of the syringe 2 . The other end of the buffer plate 41 is connected to the needle cylinder 2, and the connection method of the two can be socketed, clamped, etc. When the cleaning needle 1 connected with the syringe 2 moves up and down during the cleaning operation, the spring 42 can play a rebound effect by using the inertia, forming a good buffering effect on the instantaneous impact force up and down, and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com