Aerospace fire resisting cable and production technology thereof

A fire-resistant cable, aerospace technology, applied in the direction of insulated cables, flexible cables, cable/conductor manufacturing, etc., can solve the problems of poor reliability of fire-resistant performance, easy to fall off, difficult to ensure communication, safe and smooth power lines, etc., to achieve The effect of improving production efficiency, ensuring product quality, and reliable fire rescue response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

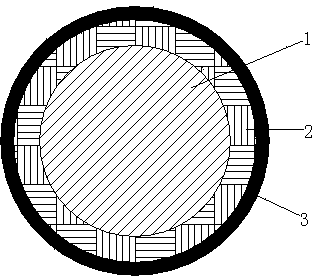

[0024] Fire-resistant cables for aerospace, including the cable core and the sheath on the cable core. The cable core is composed of a silver-plated copper conductor or a nickel-plated copper conductor 1 wrapped with a compound tape 2 for insulation, and a cross-linked ETFE sheath 3 is extruded outside the cable core. The composite tape for insulation is composed of vitrified vulcanized silicone rubber raw rubber uniformly bonded between polytetrafluoroethylene tapes and then continuously extruded, rough rolled, and fine rolled.

[0025] The production process of fire-resistant cables for aerospace, including the following steps:

[0026] 1) The ceramic vulcanized silicone rubber raw rubber in the flow state of the cured ceramic silicone rubber material is evenly bonded between the polytetrafluoroethylene tapes, and then the polytetrafluoroethylene tapes are continuously extruded, rough rolled, and finely Rolling to produce a composite tape for insulation with strong adhesion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com