Device for automatically preparing analysis test samples of scales and corrosion products of power station

A technique for analyzing corrosion products and samples, which is applied in the preparation of test samples, grain processing, food science, etc., can solve the problems of low labor efficiency, time-consuming and labor-intensive work process, etc., and achieve reduced workload, reliable device performance, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

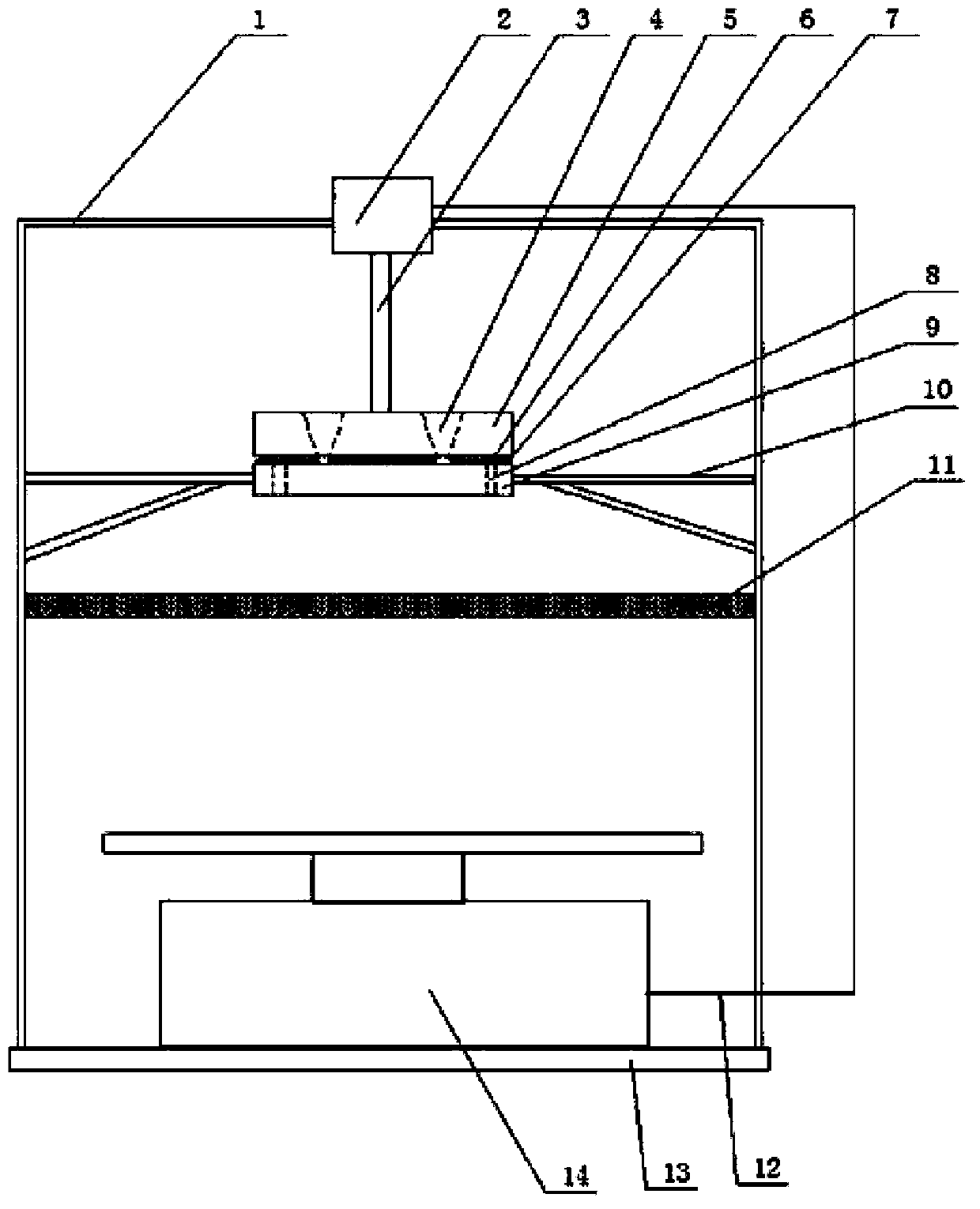

[0016] An automatic preparation device for power plant scale and corrosion product analysis samples, such as figure 1 As shown, the base 13 and the square support 1 fixed on the base, the motor 2 is fixed in the middle part of the top of the support, the motor shaft 3 is vertically downward, the lower end is fixedly connected with the upper grinding disc 5 placed horizontally, and the center of the upper grinding disc reaches to There is a blanking hole 4 passing through the upper millstone between the edges, and a hemispherical upper grinding agate particle 6 is formed on the lower surface of the upper millstone, and the lower millstone 9 is fixedly mounted below the upper millstone through a beam 10 fixedly conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com