Steel-ball outputting, screening and filling device for ball mill

A technology of filling equipment and screening equipment, which is applied in the direction of filter screen, magnetic separation, solid separation, etc., which can solve the problems of cumbersome screening operation, penetration, and easy wear of screen holes, etc., to achieve simple overall structure, reduce use cost, and avoid accumulation stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described based on the above-mentioned drawings.

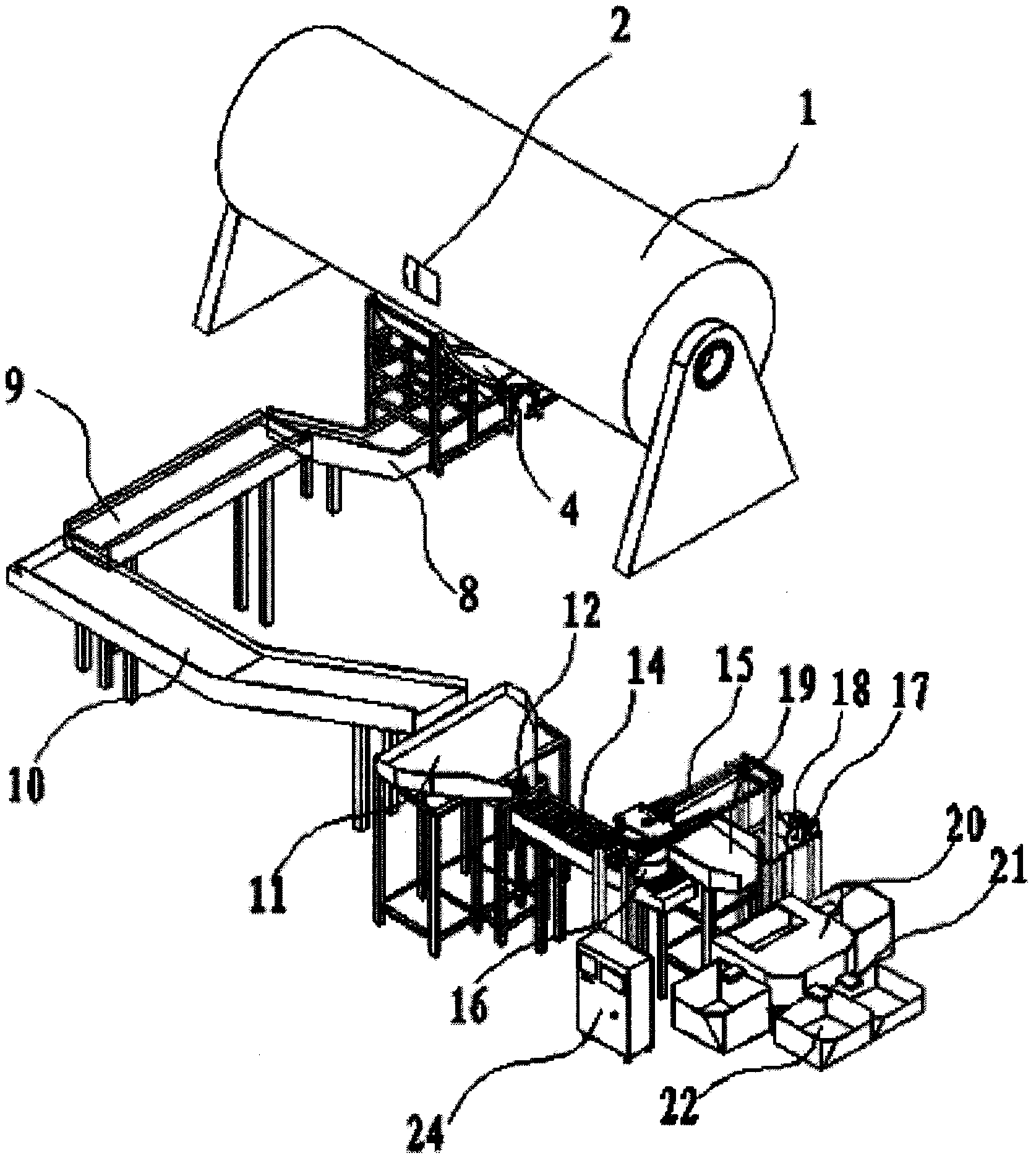

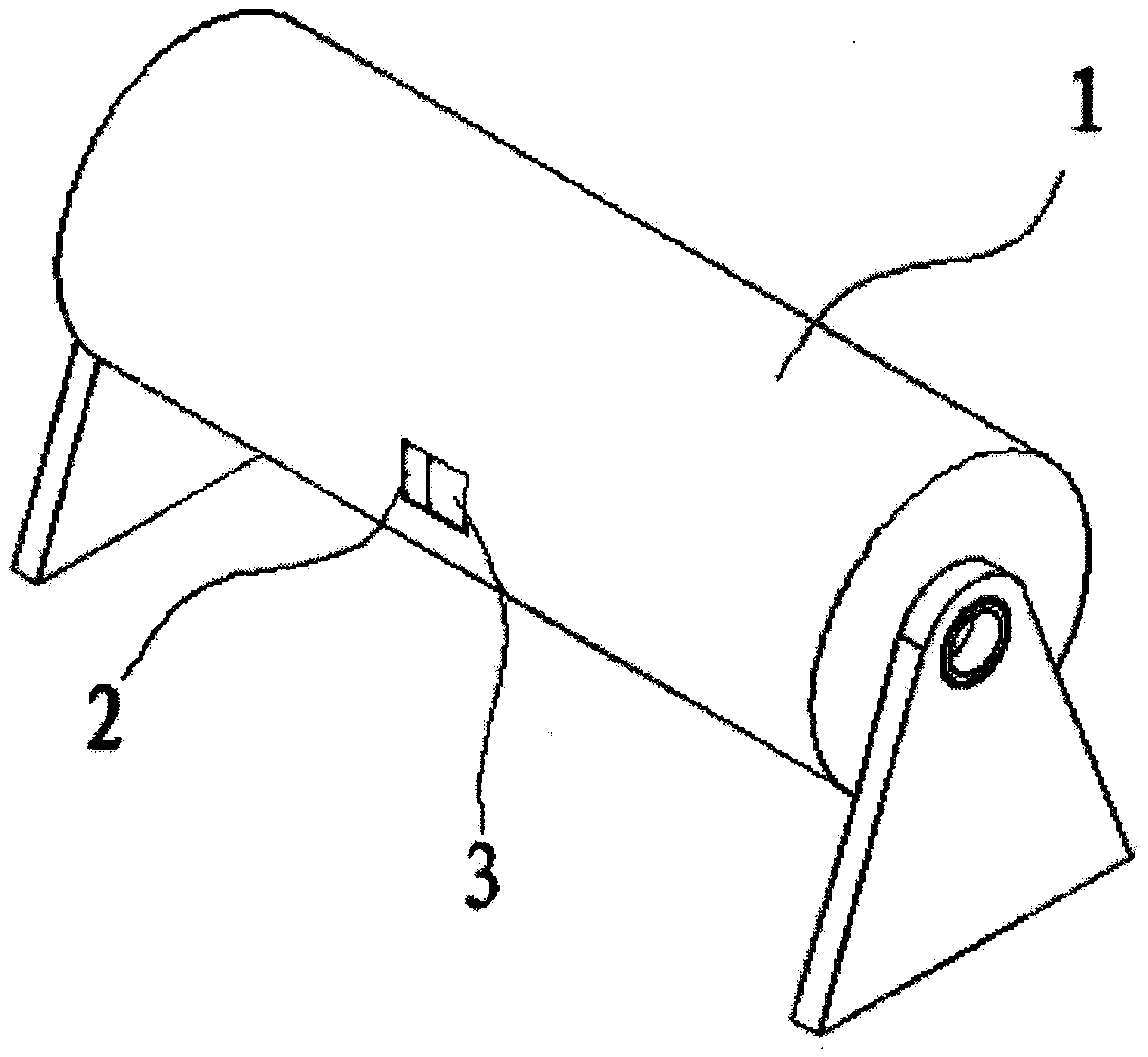

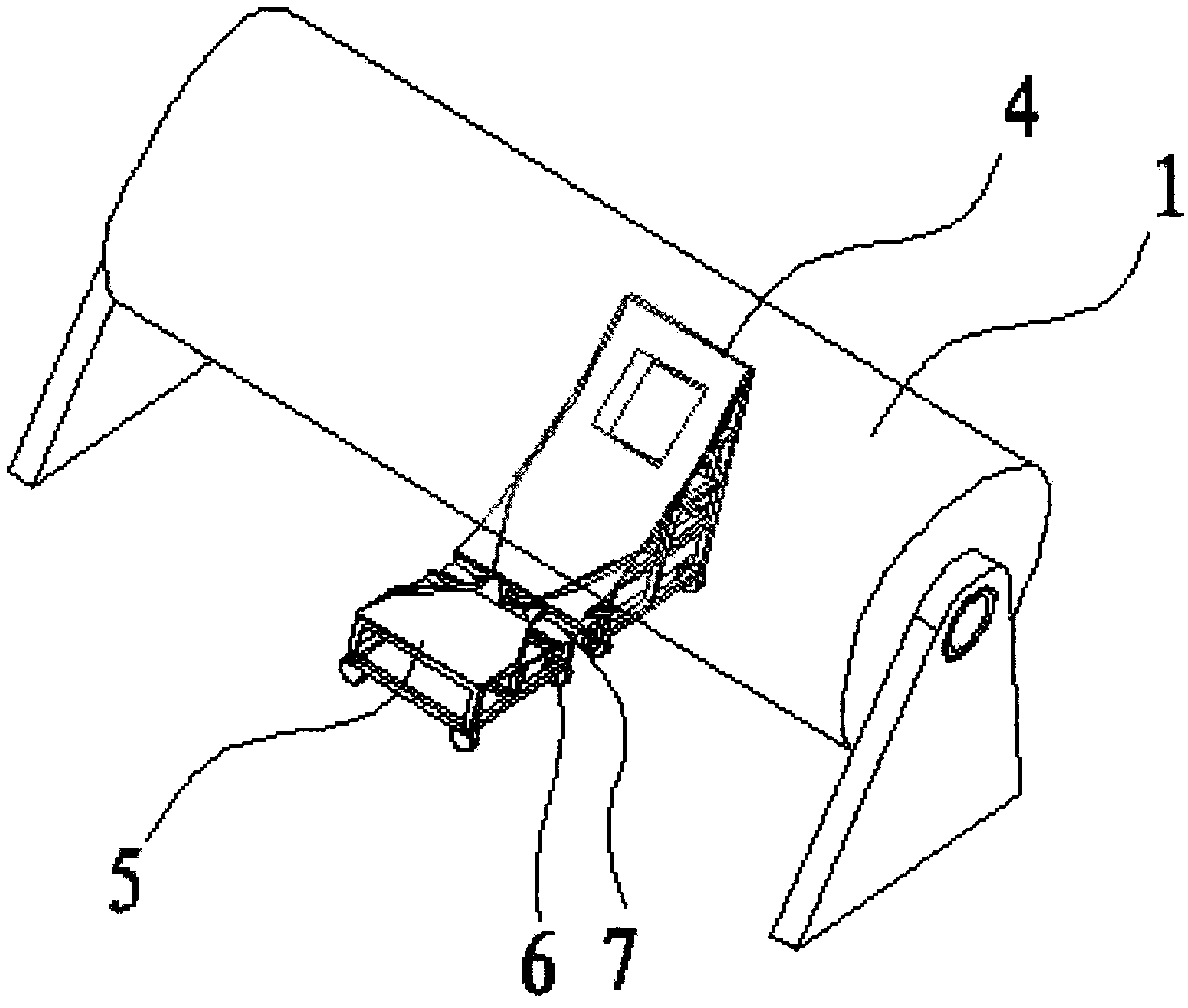

[0029] Figure 1-7 As shown, a ball mill steel ball output, screening, and filling equipment includes an output part, a conveying part, a material distributing part, a screening part, a filling part and an electrical control part 24 . The output part includes an output port 2 arranged on the ball mill 1, a material falling protection conveying line 4 and an equal hopper 5. The output port 2 is provided with a width-limiting door 3 that can slide to adjust the opening width of the output port, and one end of the material falling protection conveying line 4 Corresponding to the output port 2, the other end of the falling protection conveying line 4 corresponds to the waiting hopper 5, and the outlet of the waiting hopper 5 corresponds to conveying 7 points, and the waiting hopper 5 outlet is equipped with a waiting material rotation for pushing the steel ball in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com