Electric conductor of welding clamp

A technology of conductors and welding pliers, applied in electrode accessories, welding rod characteristics, etc., can solve the problems of easy loosening of crimping screws, poor contact, hot handles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Describe in detail below in conjunction with accompanying drawing and embodiment:

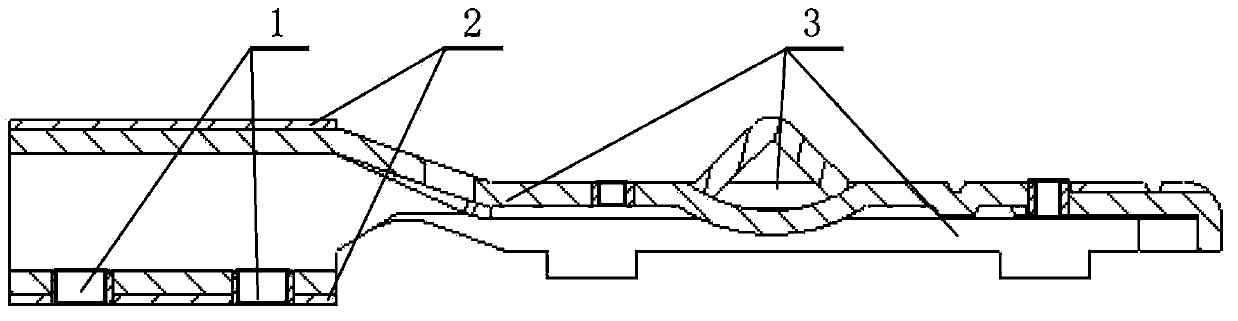

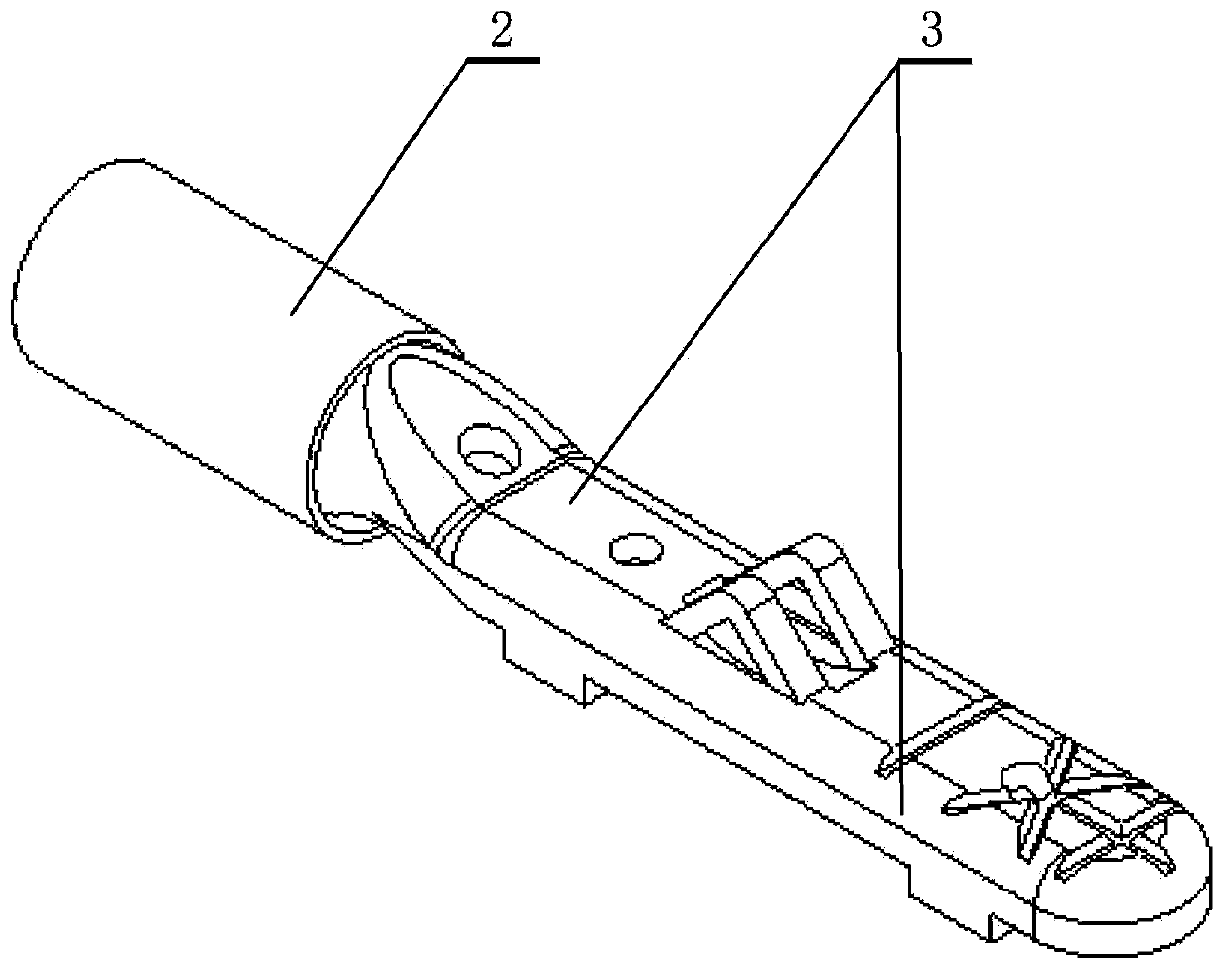

[0010] figure 1 It is an electric welding tongs electrical conductor of the present invention. Including the conductor, the main points are: the terminal of the conductor 3 is provided with a tubular sheath 2, and the tubular sheath 2 is provided with a crimping screw screw hole 1.

[0011] In order to improve the strength, make the tubular sheath 2 difficult to deform and reduce the cost, the tubular sheath 2 in the figure is a circular tubular sheath. Apparently, the tubular sheath 2 can also be a flat, square or shaped tubular sheath. That is, the cross-section of the tubular sheath 2 is circular, or tubular sheaths such as flat, square, and special-shaped.

[0012] In order to improve the physical properties of the tubular sheath 2, make it difficult to deform, ensure that the crimping screw is not easy to loose, make the wiring more stable, and reduce the cost, the tubular sheath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com