Device for reinforcement, energy dissipation and seismic mitigation of tenon and mortise joint of timber structure

A technology of shock absorbing device and wooden structure, which is applied in the direction of earthquake resistance, building components, building structure, etc. It can solve problems such as difficulty in restoring the position, impact on building appearance, hidden safety hazards, etc., achieve high social significance and economic benefits, and reduce maintenance and repair cost, the effect of convenient construction and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

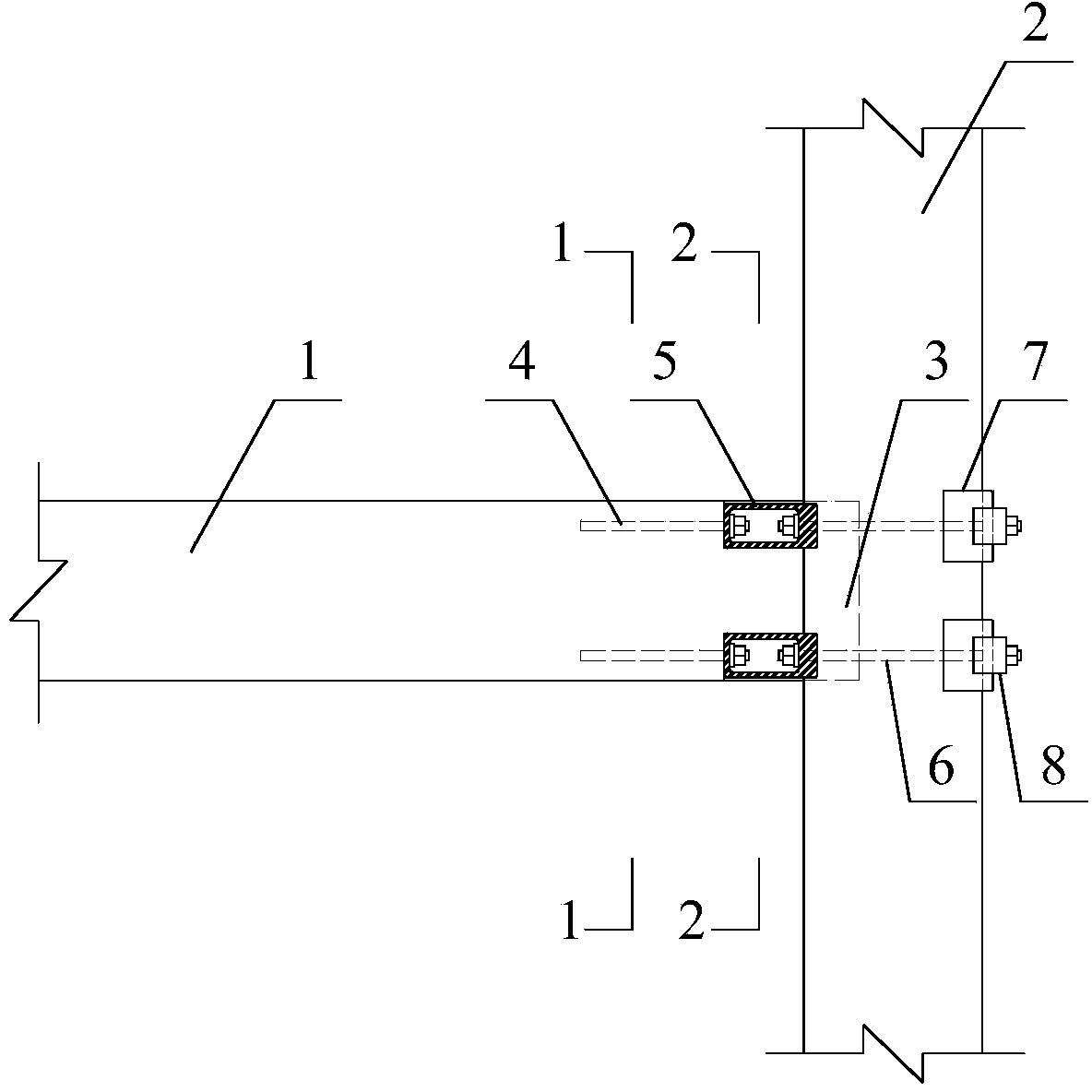

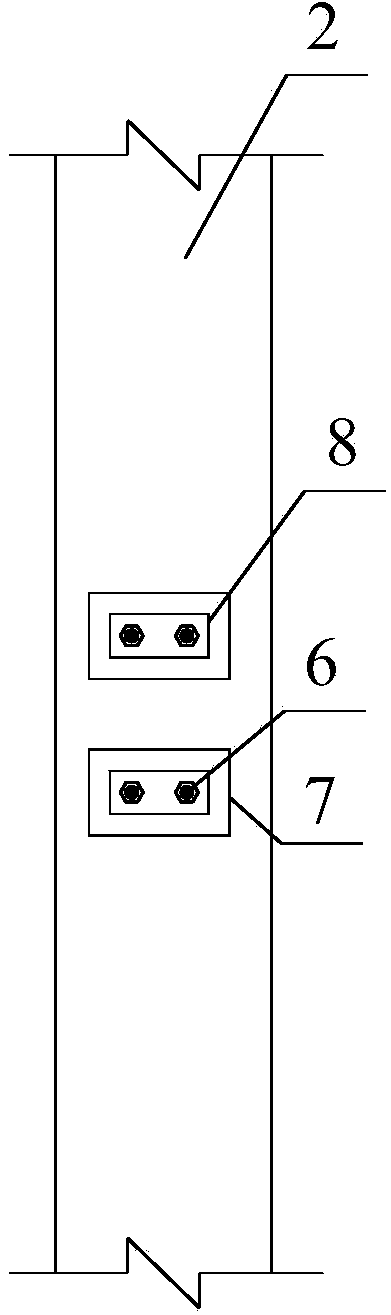

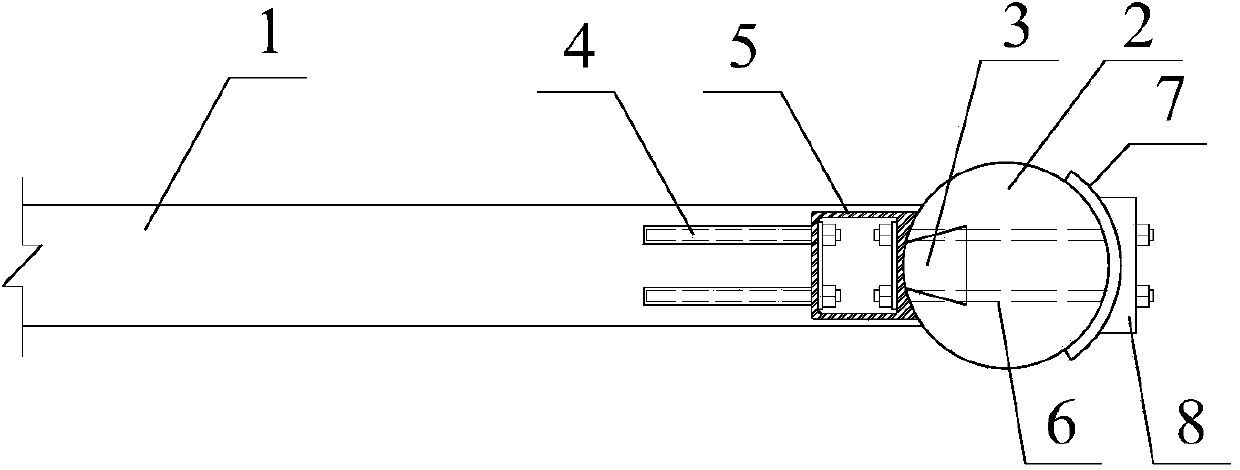

[0035] Such as Figure 1-7 As shown, a reinforcement and energy-dissipating shock-absorbing device for a wooden structure mortise and tenon joint, including a wooden beam 1, a wooden column 2, a mortise and tenon joint 3, planting bars 4, a node connector 5 and a node fastener 6, the The wooden beam 1 and the wooden column 2 are connected by mortise and tenon joints 3. The upper and lower surfaces or both sides of the beam end of the wooden beam 1 are provided with grooves 9, and the planting bars 4 are pre-planted in the groove 9, and passed through the The strip 10 is closed with special structural glue, one end of the node connector 5 is connected to the planting reinforcement 4, and the other end is connected to the node fastener 6, the node fastener 6 runs through the column body of the wooden column 2, and passes through the anchor plate 7 And spacer 8, on wooden column 2, fix on the side facing away from wooden beam 1.

[0036] Such as Figure 8-10 As shown, the node ...

Embodiment 2

[0039] Such as Figure 11 As shown, a reinforcing and energy-dissipating shock-absorbing device for mortise and tenon joints of a wooden structure, the rest of the structure is the same as that of Embodiment 1, the difference is that the cross-section of the wooden column 2 is square.

Embodiment 3

[0041] Such as Figure 12 with 13 As shown, a reinforcement and energy-dissipating shock-absorbing device for mortise and tenon joints of a wooden structure. The rest of the structure is the same as that of Example 1, except that the mortise and tenon joints 3 are through tenons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com