Ultra-large hole-diameter drilling shaft drilling method

A technology of aperture and shaft, which is applied in well sinking, shaft equipment, earth-moving drilling, etc., can solve the problems of frequent maintenance, low ventilation efficiency, and hanging air ducts occupying the space of construction equipment, so as to save the heating link, eliminate the Accumulation of harmful gas and good effect of underground climatic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

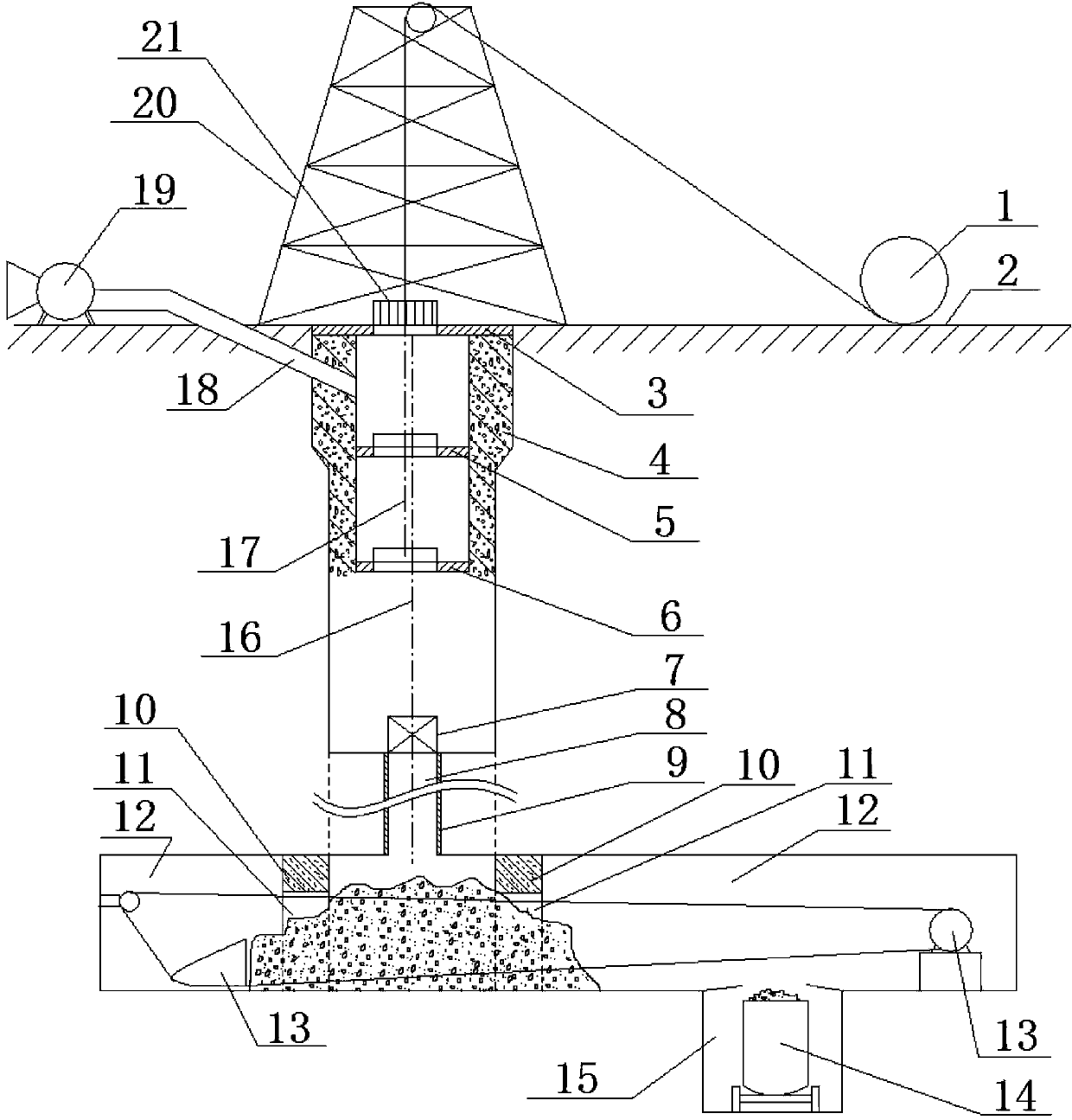

[0040] Such as figure 1 As shown, the method of drilling a vertical shaft with an extra-large aperture includes drilling, wellhead expansion and well neck construction, installation of equipment, construction of the foundation wall of the wellbore, installation of ballast transportation equipment, reaming of the hole to form a well, and construction of the well wall. Its characteristics are: The concrete steps of its method are as follows:

[0041] (1) Drilling:

[0042] a. Use a drilling rig to drill a hole 8 at a predetermined position, with a diameter of 700mm, and connect it with the underground communication lane 12;

[0043] b. Use sprayed cement mortar to support the hole wall, with a wall thickness of 30mm;

[0044] c. installing a high-strength hole-protecting wear-resistant pipe 9 in the borehole;

[0045] (2), wellhead expansion and well neck 4 construction:

[0046] a. Stripping the topsoil at the wellhead;

[0047] b. Construction of wellhead lock and well ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com