Variable-pitch net-shaped stay wire wind wheel

A wind wheel and mesh technology, applied in wind power generation, wind engine, wind engine control, etc., can solve problems such as cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

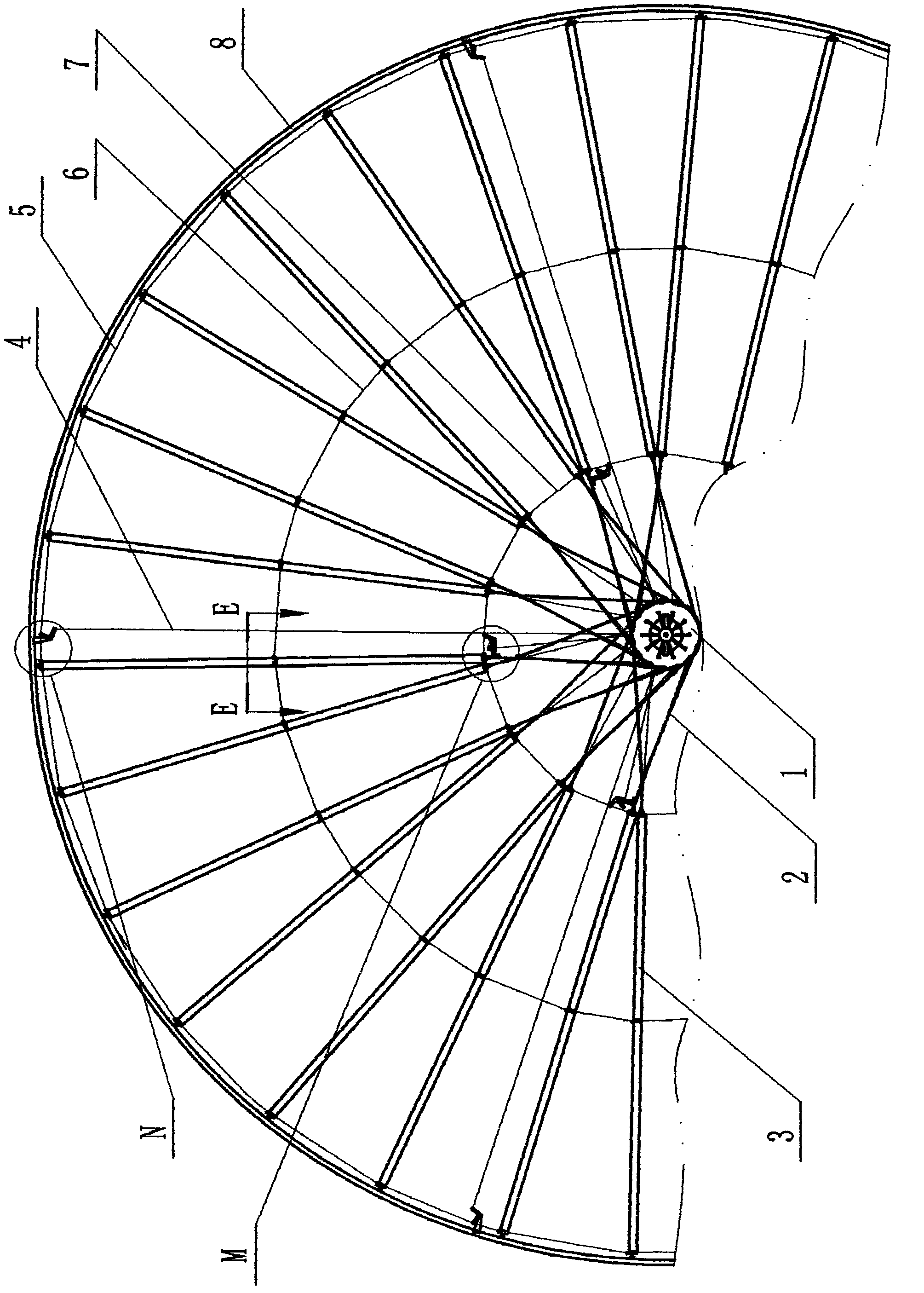

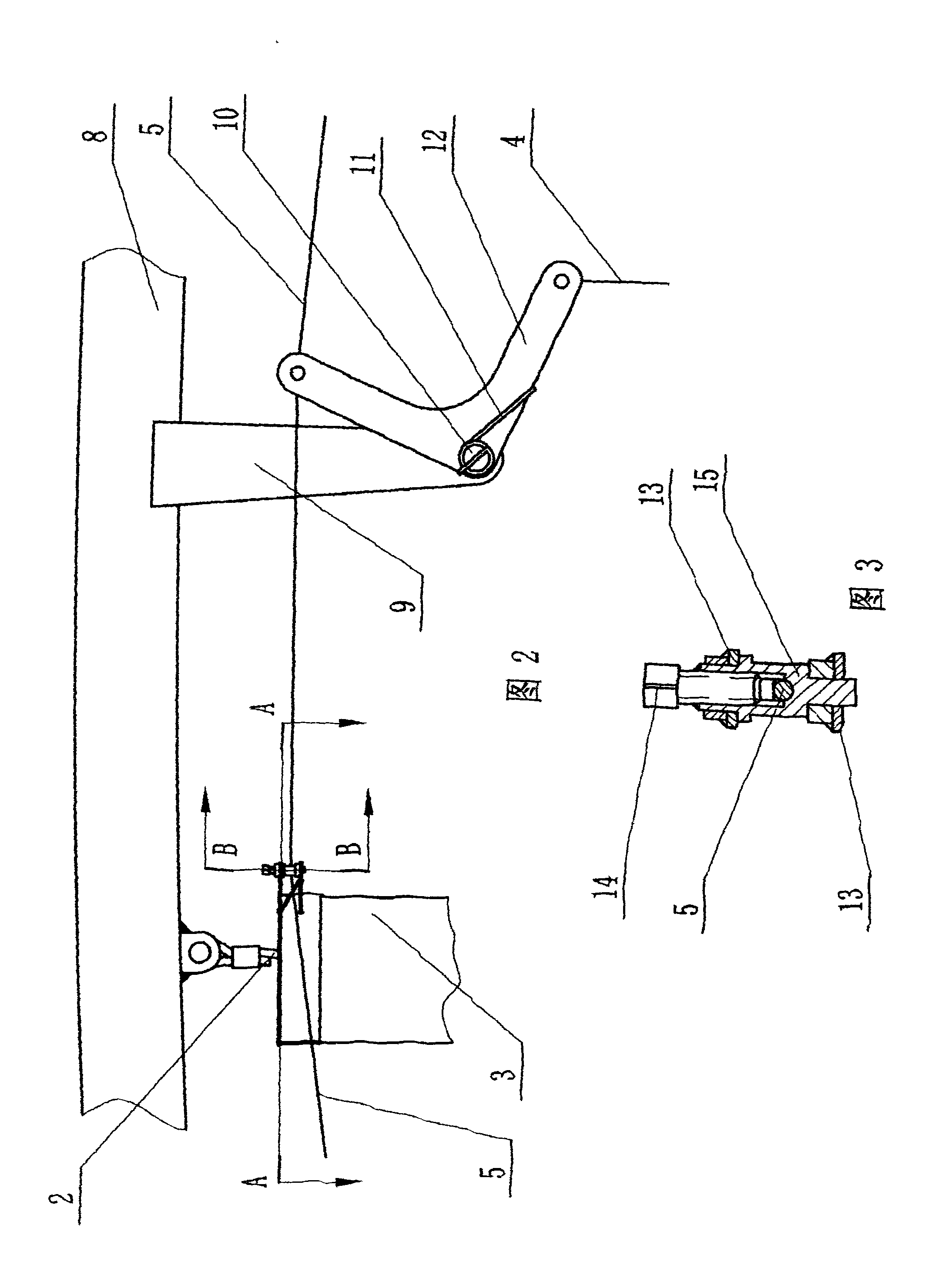

[0013] From figure 1 , 2 , 4, 6, 7, 8 can be seen that the present embodiment has wheel hub 1, wheel rim 8, blade 3 and the backguy steel rope 2 that makes wheel hub 1 and wheel rim 8 be fixed as one, and steel rope 2 is with steel rope tensioner 35 Tensioned, the steel rope 2 longitudinally passes through the inside of the blade 3, and there is a clip 18 on the blade 3, which is characterized in that: the outer end and the inner end of the blade 3 are respectively connected with a blade pitch device. The 201120373287.4 patent of the author of this paper shows the wire-guy wind wheel scheme, which shows a pitch-changing device connected to the inner ends of the blades.

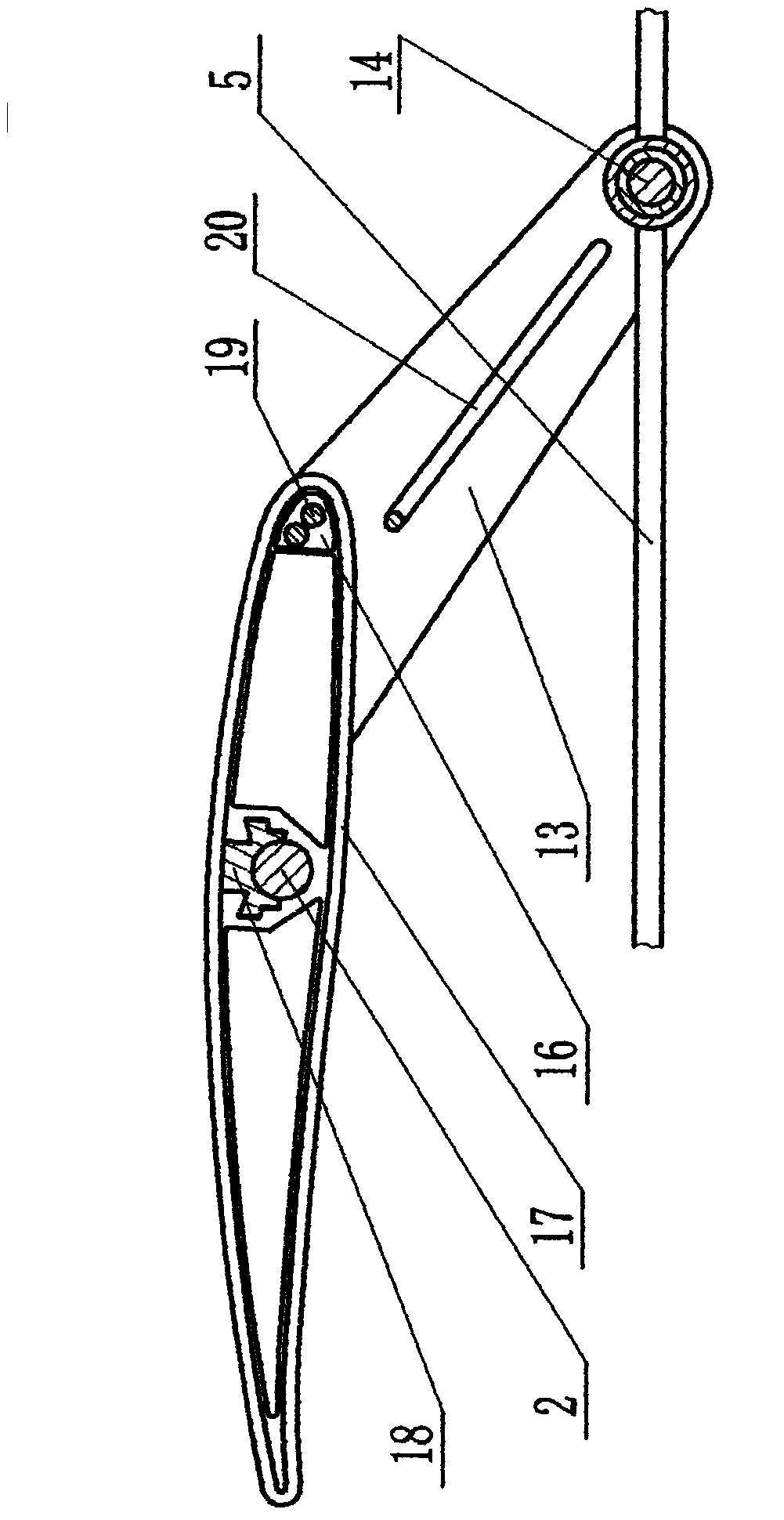

[0014] The simplest and most reliable pitch-changing device in which the outer and inner ends of the blades 3 are respectively connected is briefly described as follows: figure 2 , 4 As shown, the outer end cover 17 of the blade 3 is fixedly connected with the outer support plate 13, the reinforcing rod 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com