Wind generation set impeller assembling device and impeller assembling method

A technology for wind turbines and assembling devices, which is applied to wind turbine components, wind energy power generation, wind turbines, etc., can solve problems such as time-consuming, affecting blade pitch, and easy blade damage, and achieves wide application, simple structure design, Quick and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

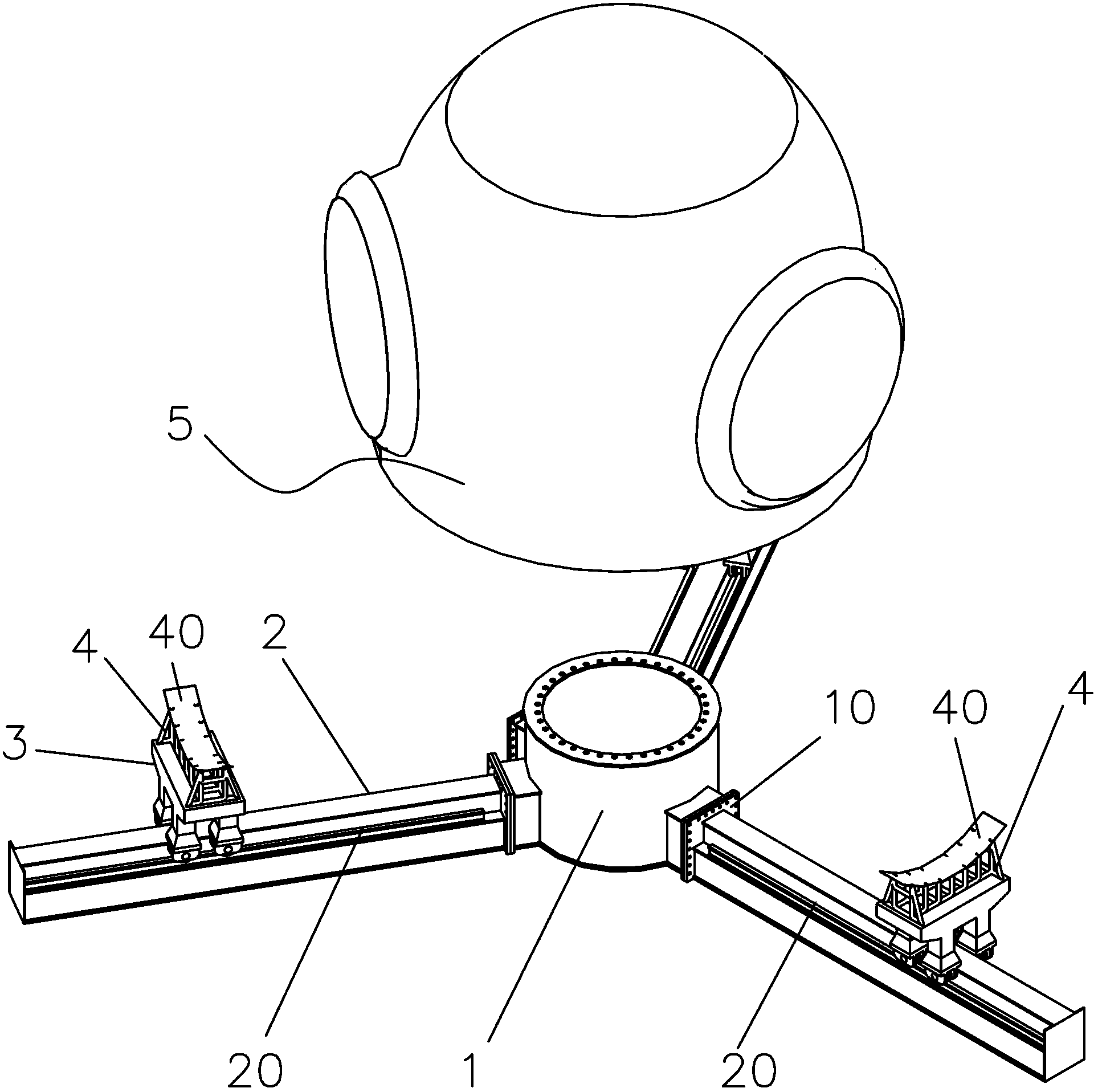

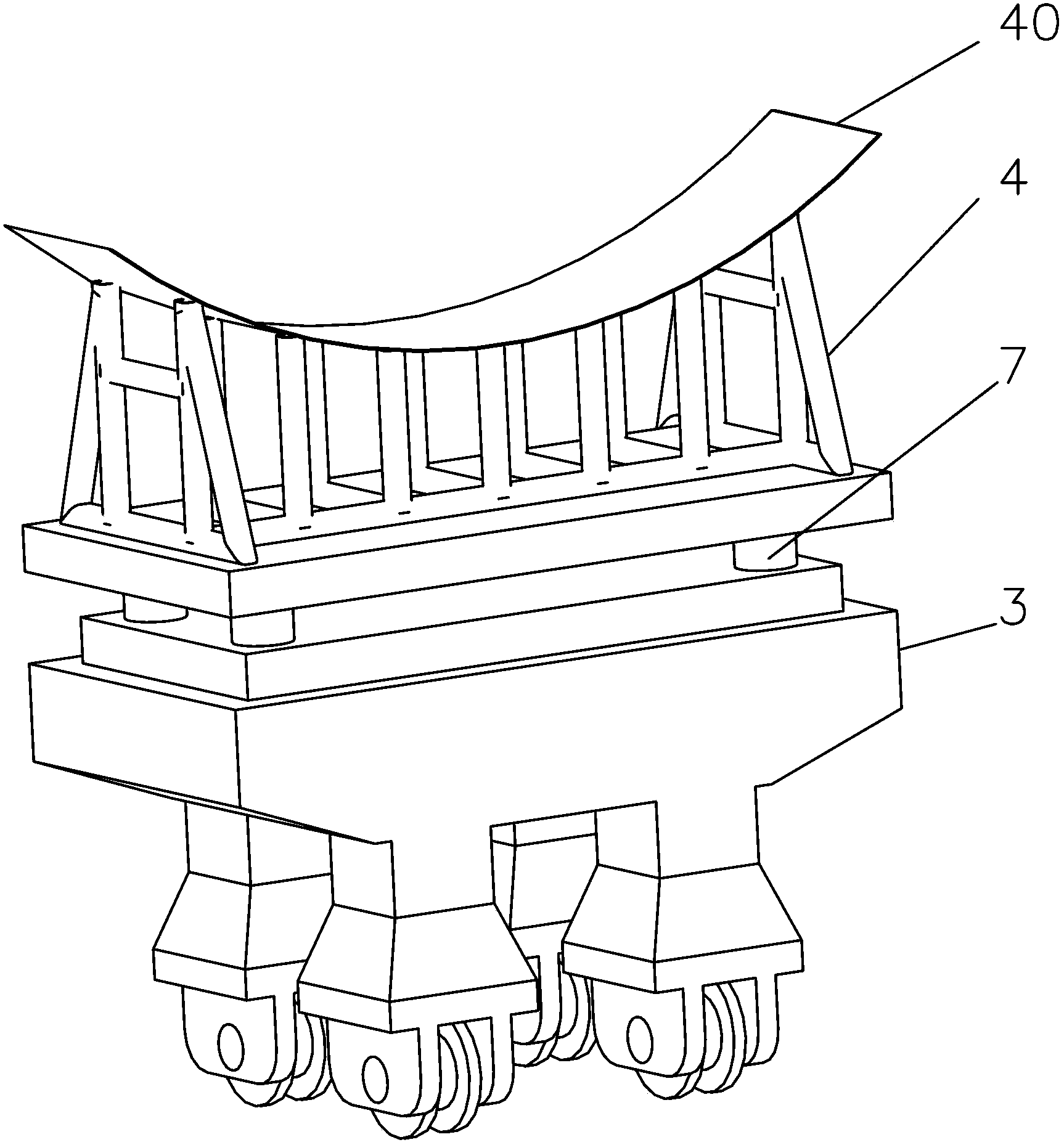

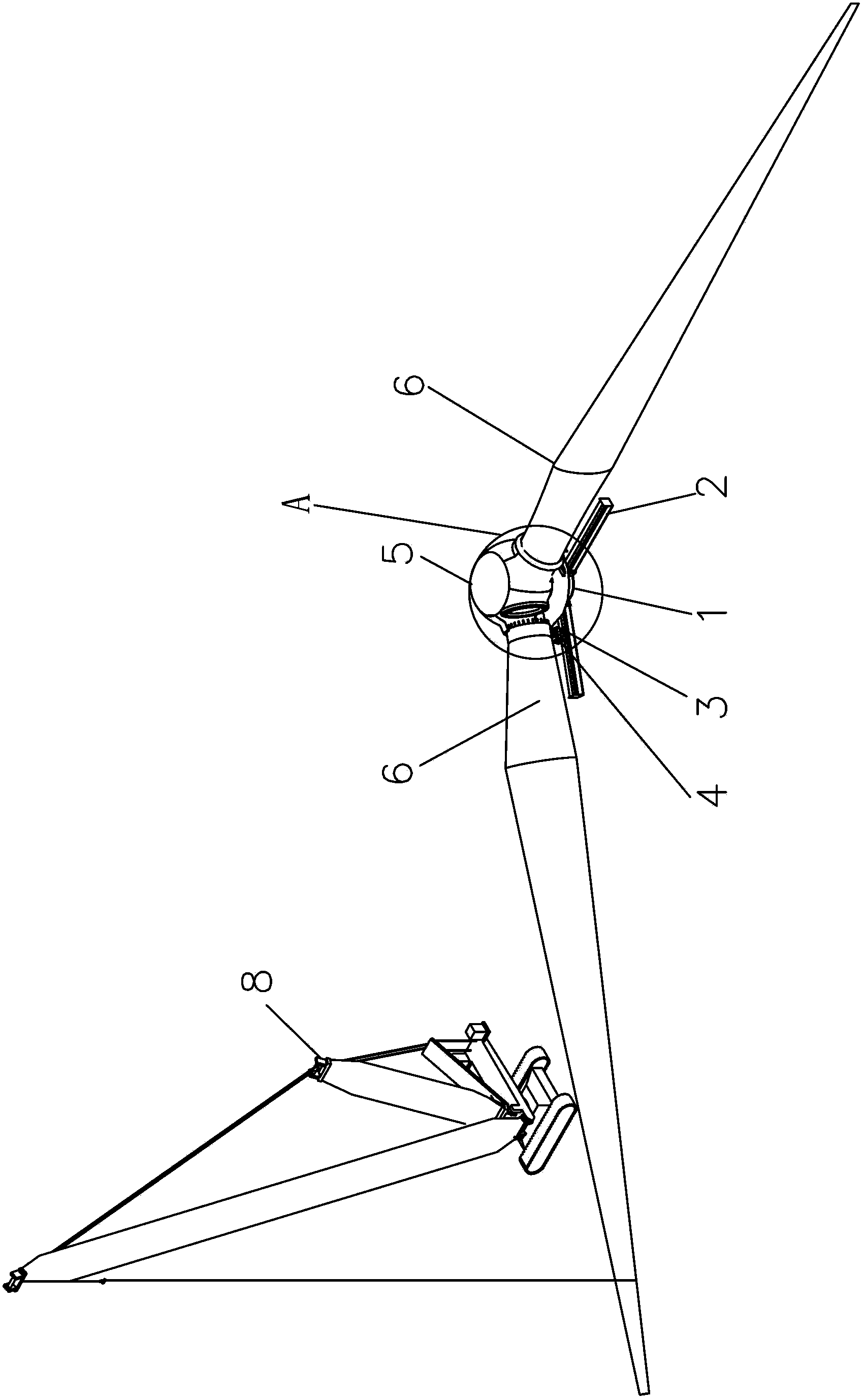

[0024] figure 1 It is a three-dimensional effect diagram of the wind turbine impeller assembly device of the present invention, as figure 1 As shown, the wind turbine impeller assembly device of the present invention includes: a mounting base 1 for positioning and supporting the hub 5; a plurality of blades 6 (such as image 3 As shown) the blade mounting device installed in alignment with the hub 5 forms an impeller assembly platform by connecting the mounting base 1 respectively; wherein, the mounting base 1 is provided with a plurality of connecting parts 10 respectively connecting multiple blade mounting devices; wherein, in When assembling the impeller, place the hub 5 on the mounting seat 1 so that each pitch bearing of the hub 5 corresponds to a blade installation device, and then place the blade 6 on the corresponding blade installation device and move to the corresponding blade installation device of the hub. A pitch bearing is used to connect them together, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com