Method for manufacturing a suspension bearing device and strut comprising such a device

A technology of a bearing device and a manufacturing method, applied to the suspension system of a motor vehicle, the field of the suspension system, capable of solving problems such as satisfactory reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

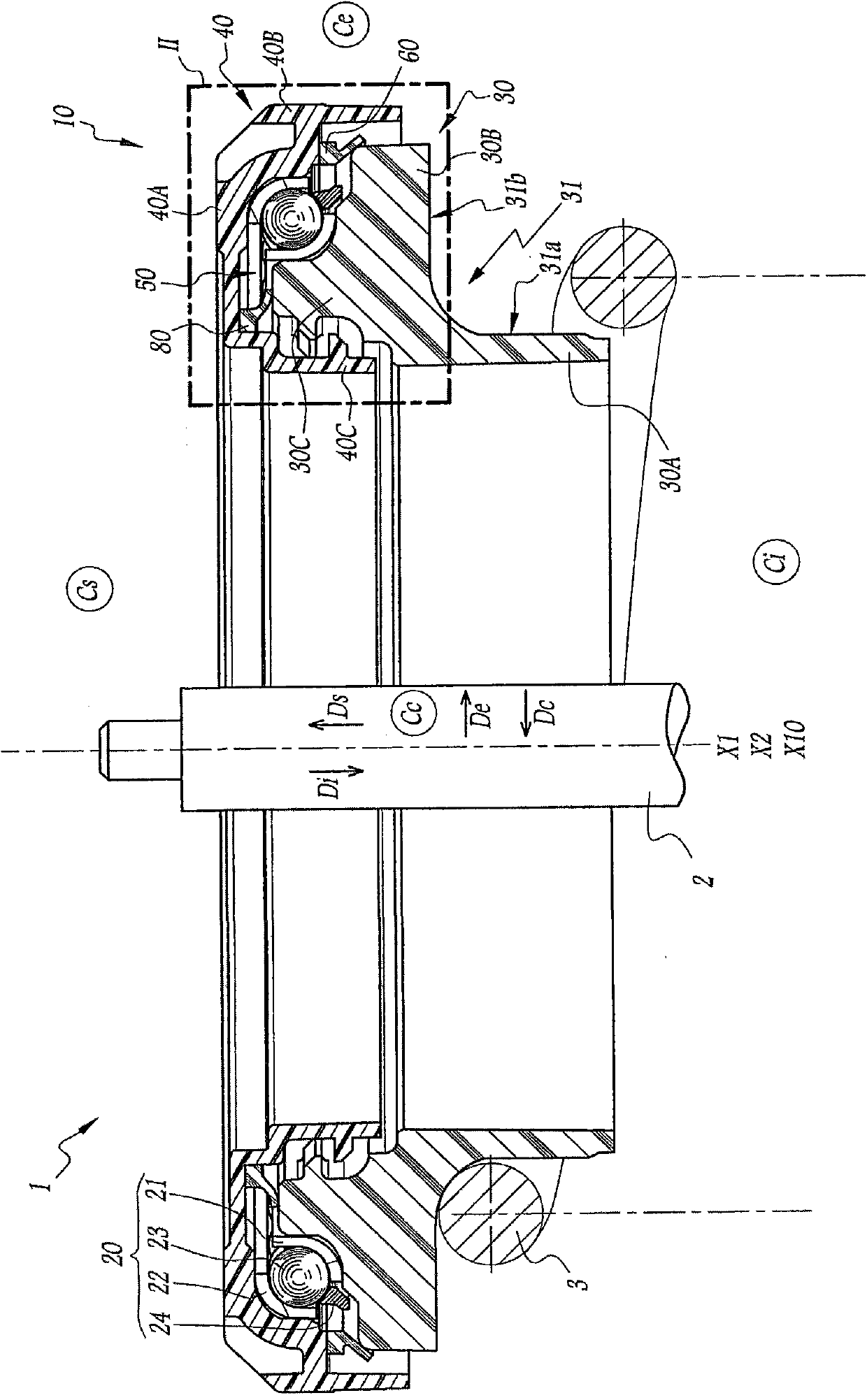

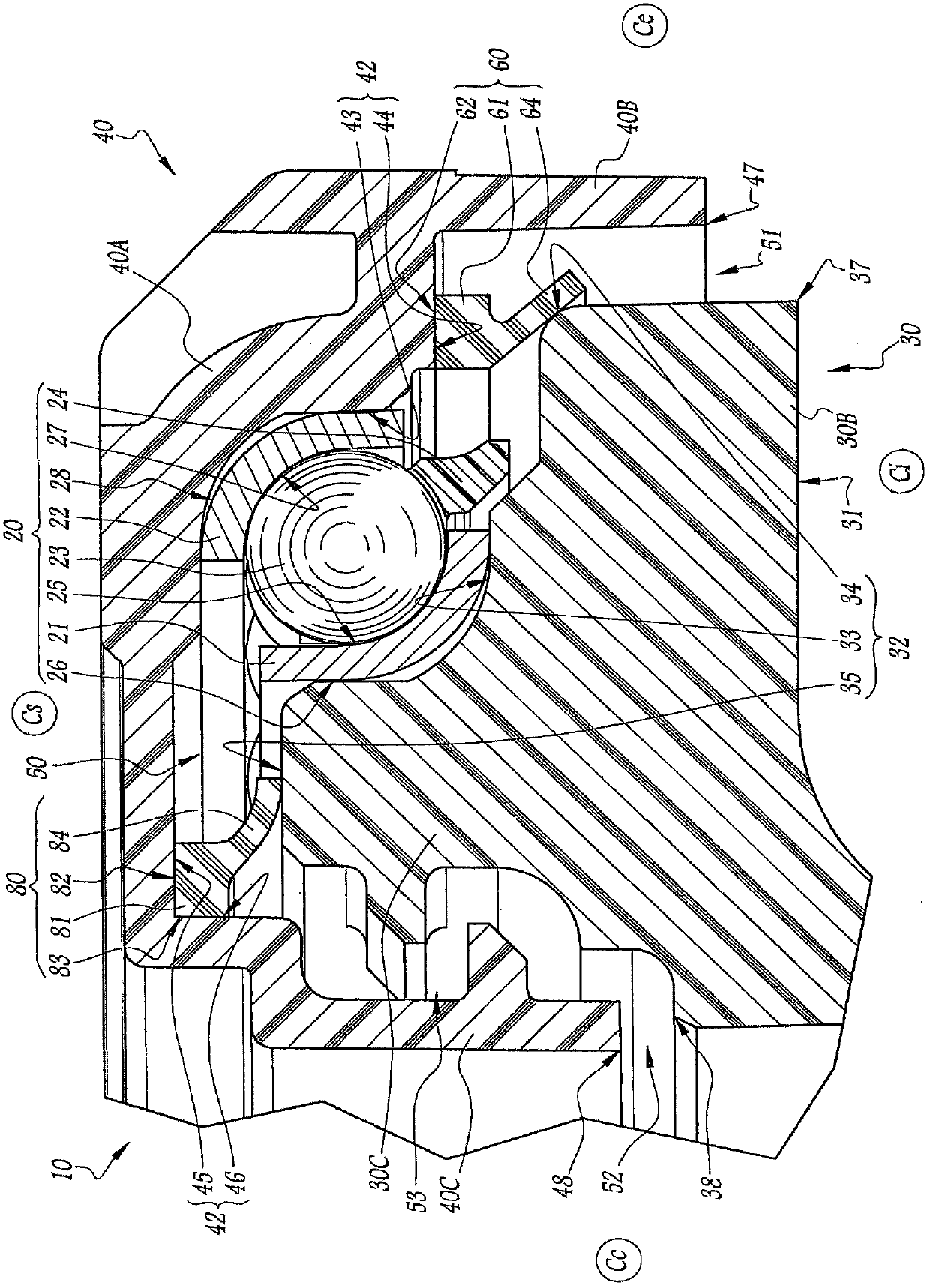

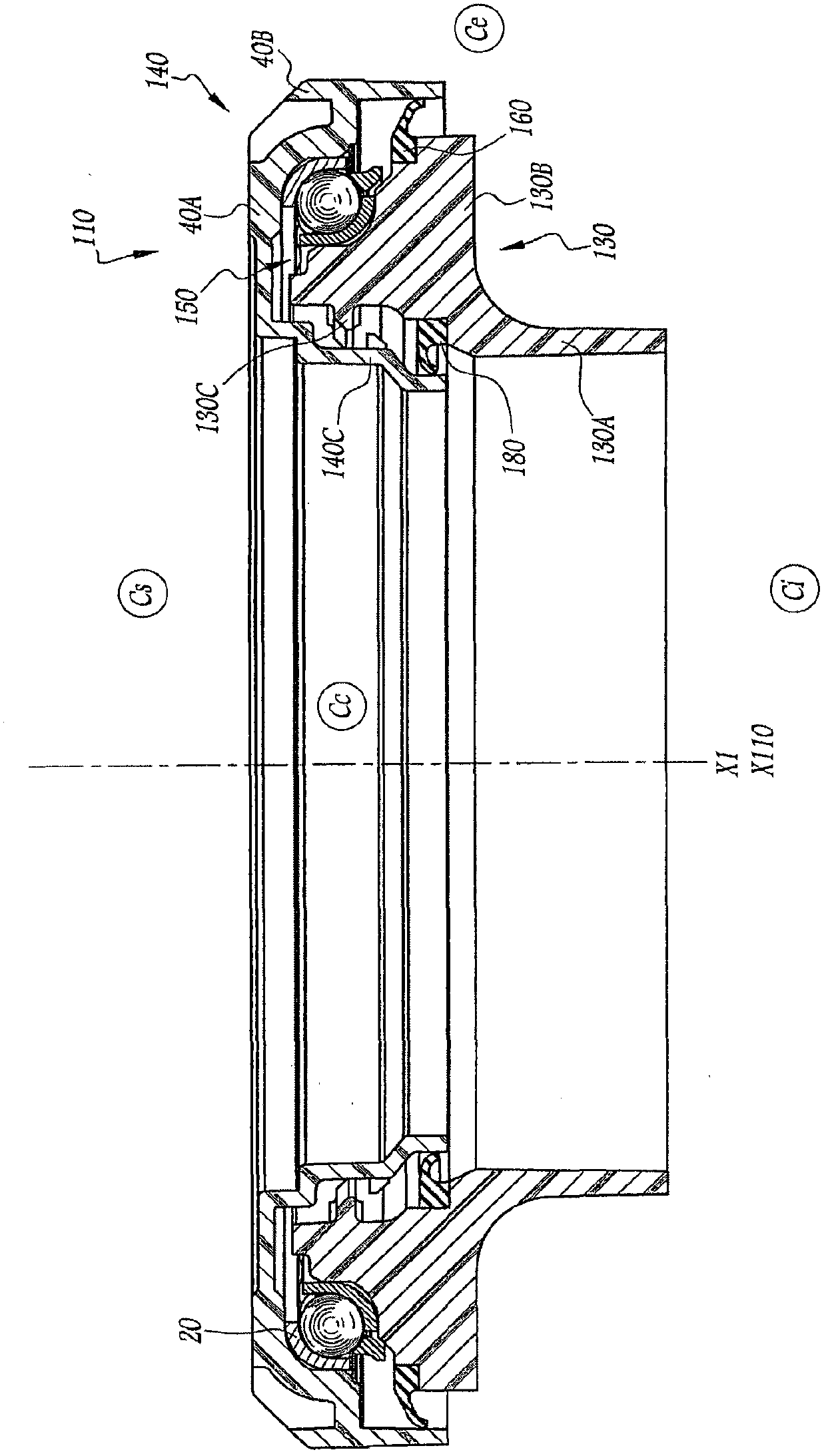

[0030] figure 1 with 2 A suspension bearing arrangement 10 according to the invention is shown, suitable for mounting to a strut 1 also according to the invention.

[0031] Pillar 1, partly in figure 1 Shown in, belongs to the motor vehicle suspension system. The struts 1 support the axles and wheels of the vehicle, not shown for sake of clarity. When the wheels of the vehicle are at rest on a flat road, the strut 1 extends along a main axis X1 which is in a substantially vertical direction. The strut 1 includes a suspension spring 3 , a suspension bearing arrangement 10 and a shock absorber piston including a piston body and a shock absorber rod 2 . Rod 2 and spring 3 are in figure 1 The middle part is shown, while the piston body is not shown for the sake of brevity.

[0032] In the following, for easier spatial identification of the device 10 , a bottom side Ci is defined, on which the road and the wheels of the vehicle are located, and a top side Cs opposite the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com