Light emitting diode module

A technology of light-emitting diodes and light-emitting elements, which is applied in the direction of light source, electric light source, light source fixing, etc., can solve the problems of inability to control the reflection angle of the light-emitting diode chip, poor thermal conductivity of the insulating layer, etc., and achieve the effect of easy positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Relevant technical content and detailed description of the present invention, cooperate accompanying drawing to illustrate as follows:

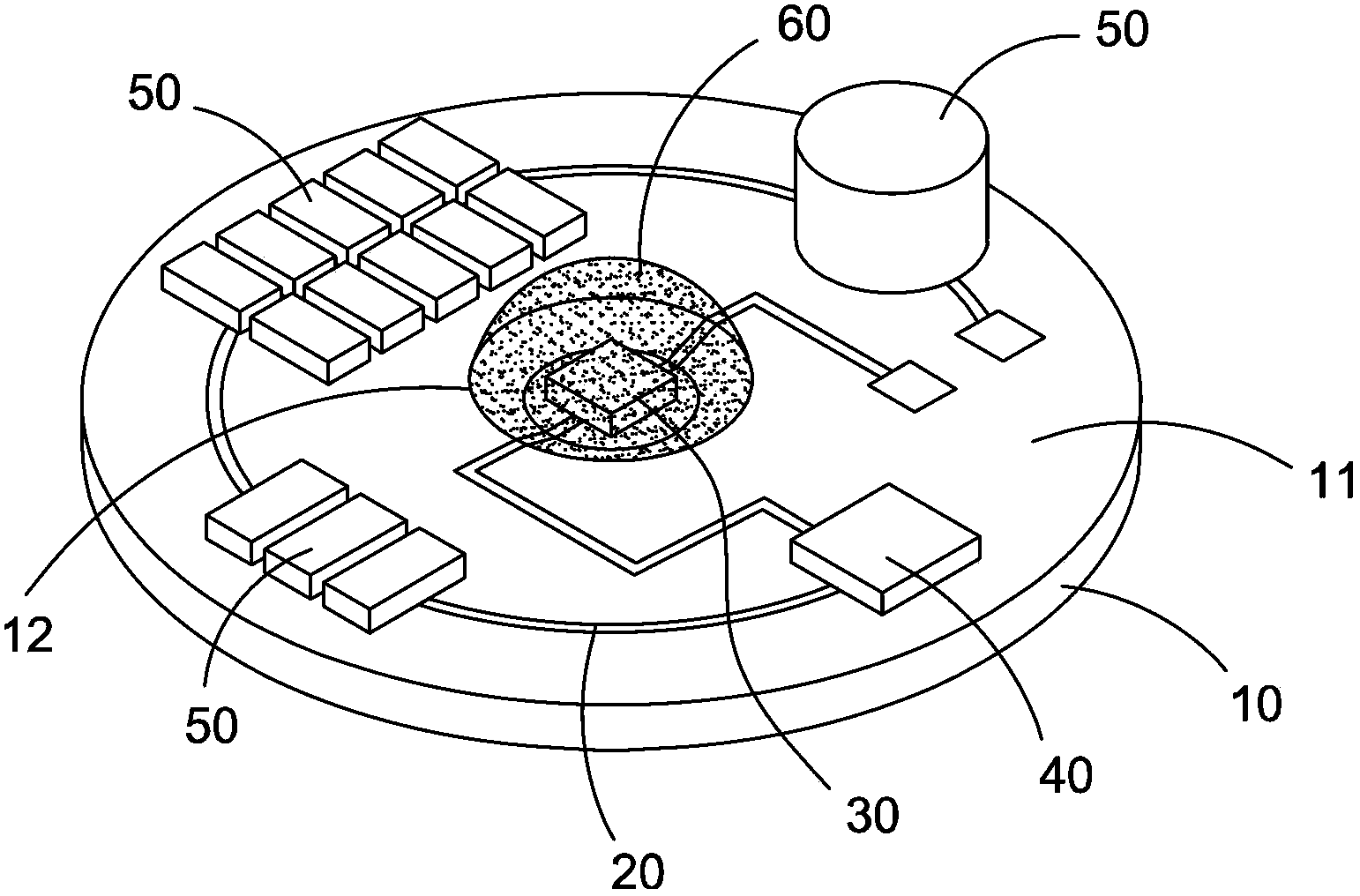

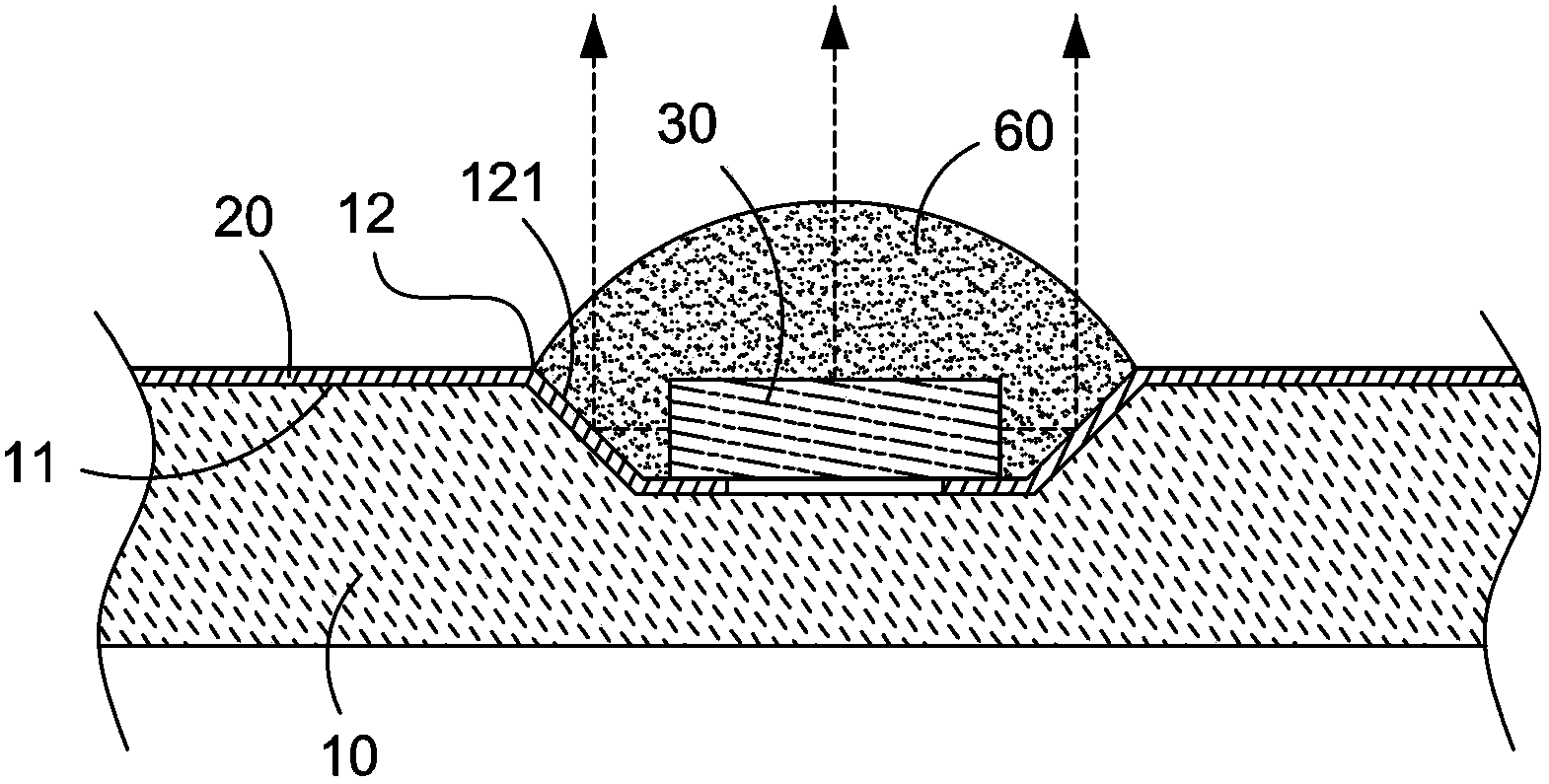

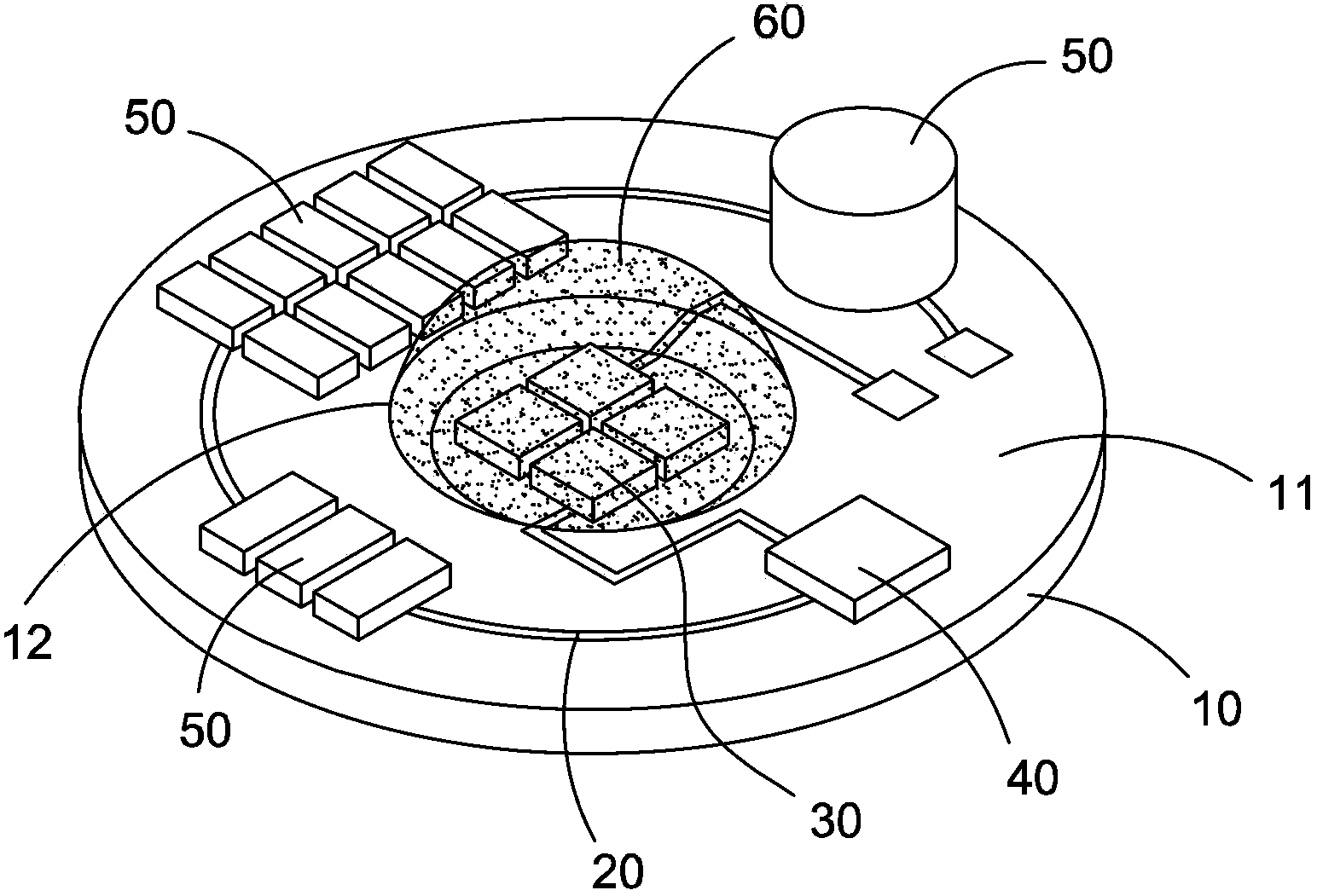

[0031] Such as figure 1 As shown, the LED module according to an embodiment of the present invention includes a ceramic substrate 10 , a circuit layer 20 , a light emitting element 30 , a driving circuit element 40 , and a plurality of electronic elements 50 .

[0032] The ceramic substrate 10 has a groove 12 on the upper surface 11 thereof. The ceramic substrate 10 is formed by sintering ceramic powder. Through appropriate mold matching, the ceramic substrate 10 has the groove 12 when it is formed, without using other subsequent processing methods to make the groove on the general flat ceramic material, which can avoid the difficulty of processing the high-hardness ceramic substrate. difficulty.

[0033] The circuit layer 20 is located on the upper surface 11 of the ceramic substrate 10 . The circuit layer 20 is made of copper or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com