Vacuum precise displacement device

A precision displacement and vacuum technology, applied in the field of vacuum instruments, can solve the problems that the displacement device cannot be installed, the instrument or device cannot be installed, etc., and achieves the effect of saving the installation area, compact structure and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

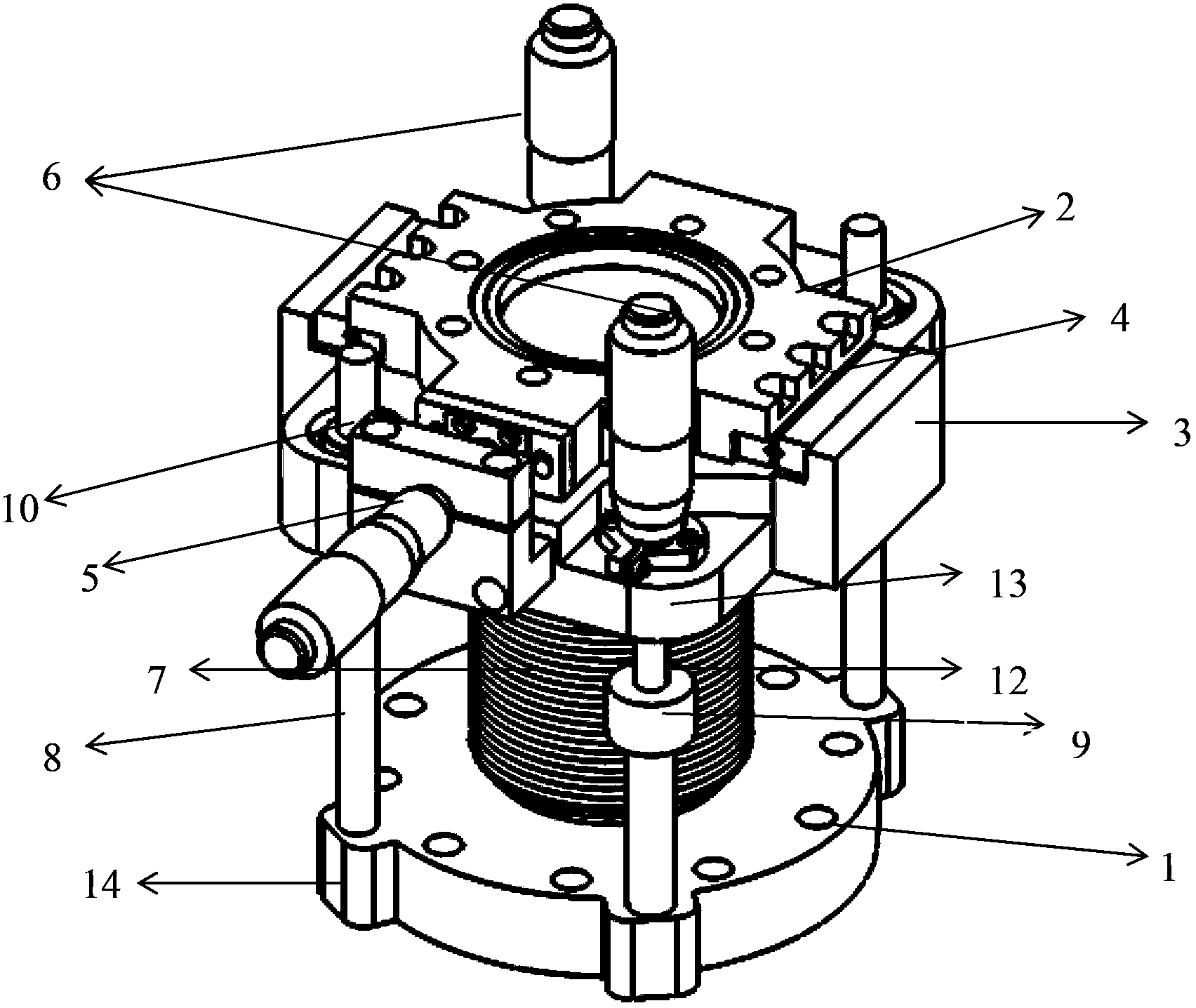

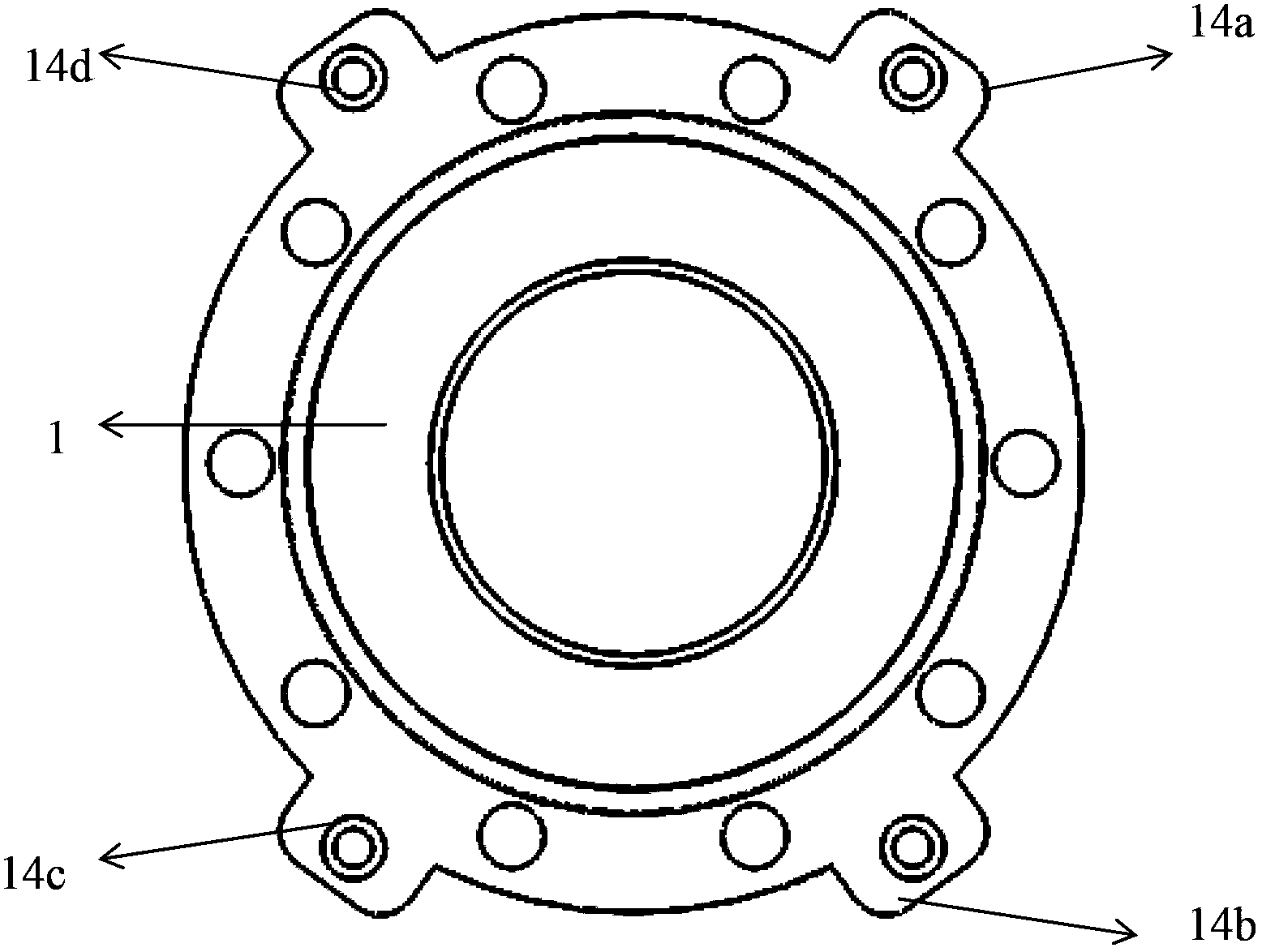

[0020] The present invention generally provides a vacuum precision displacement device, including: a bottom flange 1 installed on the vacuum chamber; a top flange 2; a bellows 7 connecting the bottom flange 1 and the top flange 2, and the axis of the bellows 7 The direction is defined as the longitudinal direction; it is used to install the displacement platform 3 of the top flange 2, and the top flange 2 can move in translation relative to the displacement platform 3; it is used to drive the motion mechanism of the top flange 2 to move. The motion mechanism includes a first motion device 5 and a second motion device 6. The first motion device 5 can make the top flange 2 move in translation relative to the displacement table 3, and the second motion device 6 can make the displacement table 3 move longitudinally relative to the bottom flange 1. sports. Wherein, the second moving device 6 connects the bottom flange 1 and the translation stage 3 . The vacuum precision displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com