Device and method for testing specific surface of rock sample in isothermal adsorption instrument

A technology for testing samples and samples, applied in measuring devices, permeability/surface area analysis, instruments, etc., can solve the problems of waste of precious core materials, greater influence of specific surface errors, and distortion of pore size distribution results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be specifically described below in conjunction with the device diagram. It is necessary to point out that this embodiment is only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Researchers in this field can use the above-mentioned present invention Some non-essential improvements and adjustments are made to the present invention.

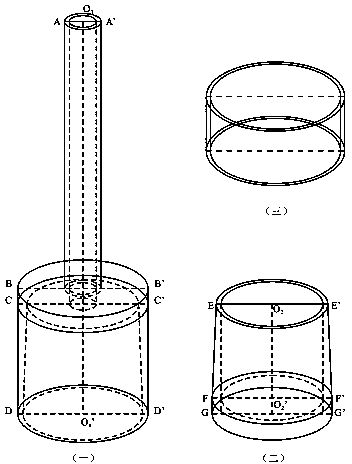

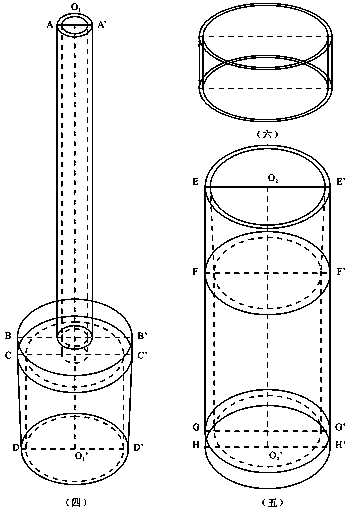

[0032] The present invention is an improvement to the device and method for testing the rock specific surface in the existing isothermal adsorption instrument, and the whole device is as attached figure 1 , attached figure 2 As shown, some of the original traditional devices can only test powder or fine particle samples with a diameter of less than 1 mm. The improved device can not only test the original traditional device samples, but also test samples with a diameter of Φ25 mm. On the premise of the pore structure of rock sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com