Product parametric yield estimation method

A yield and parameter technology, applied in the field of microelectronics, can solve the problems of complex yield estimation process, difficult operation, and integrated circuit failure, etc., and achieve the effect of small calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

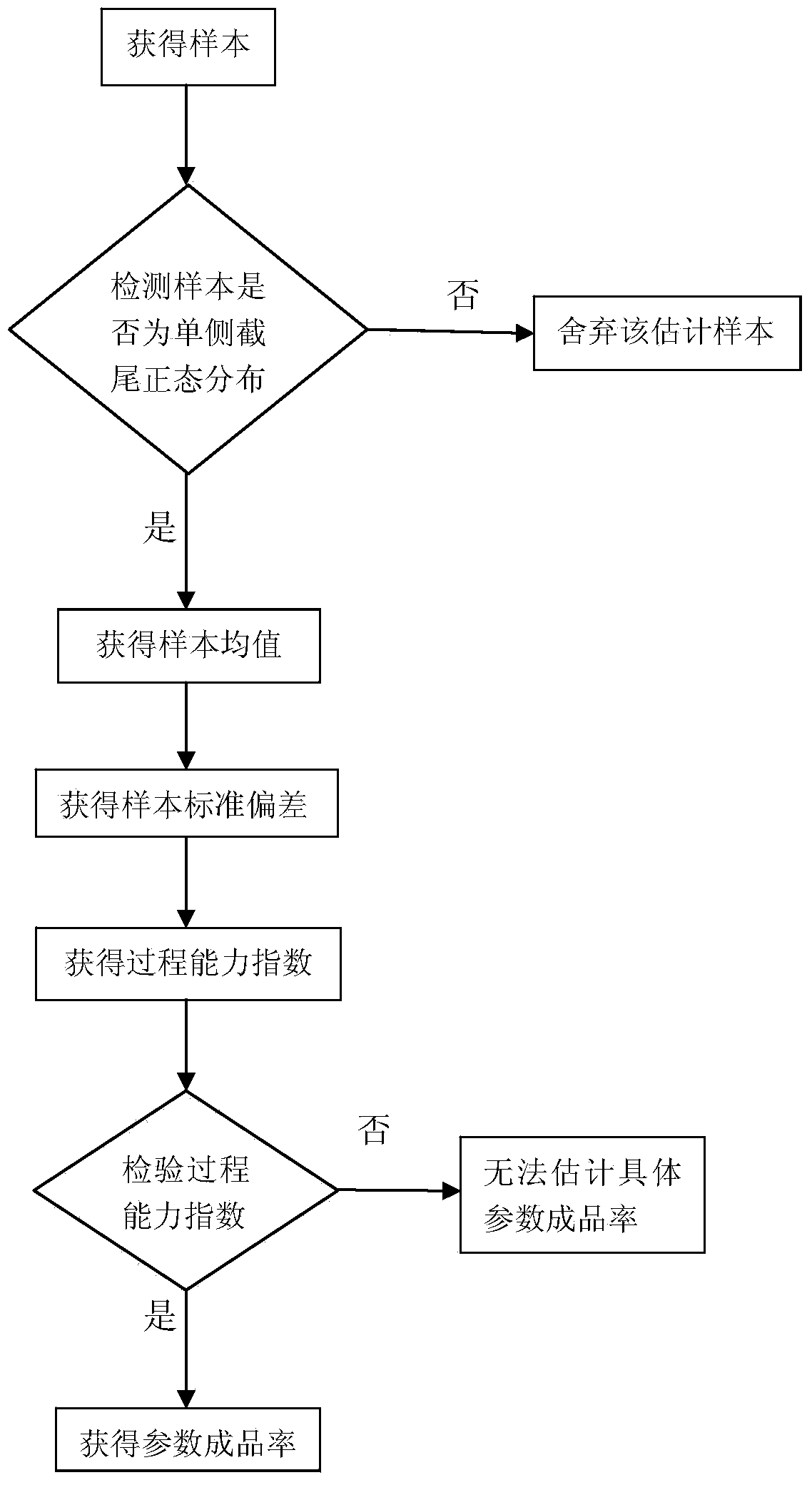

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] Refer to attached figure 1 Concrete steps of the present invention are as follows.

[0039] Step 1, get a sample.

[0040] Select the data in the product performance parameter test file with one-sided specification limit as the estimation sample.

[0041] The product performance parameter test file with a one-sided specification limit means that the performance parameter test data meeting the one-sided specification requirement set at the beginning of product design is recorded in the file.

[0042] The one-sided specification limit mentioned here refers to the performance parameters defined in the standard number JB / T3736.7-1994 of the Machinery Industry Standard of the People's Republic of China "Statistical Tools Commonly Used in Quality Management - Process Capability Index" must meet the product performance parameters The bounds of the scope that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com