Piezoelectric Linear Motor Driven by Bipeds and Electric Excitation Method

A linear motor and piezoelectric technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem that the clamping unit cannot be clamped and the parallelism of the guide rails is difficult , reduce the efficiency of movers and other issues, and achieve the effects of easy mass production, improved service life and improved motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

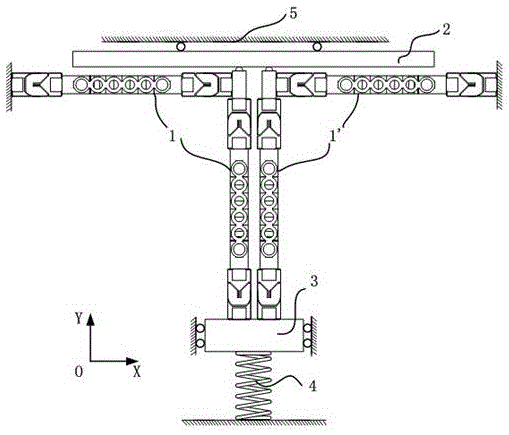

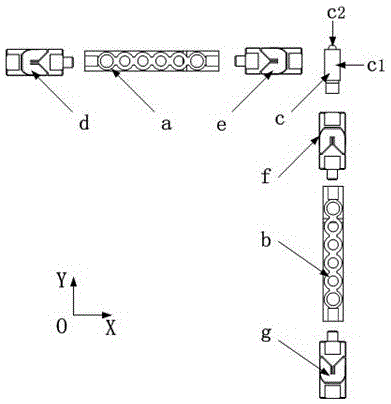

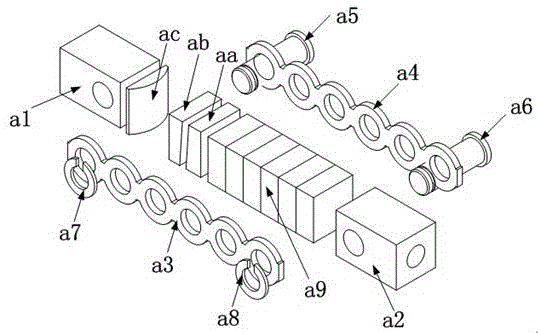

[0032] Please refer to Figure 1 to Figure 3 As shown, the biped driven piezoelectric linear motor of the present invention is composed of a first stator group 1, a second stator group 1', a mover / linear guide rail 2, a preload guide rail 3, a preload spring 4 and a base 5. Among them, the first stator group 1 and the second stator group 1' of the piezoelectric linear motor are symmetrically distributed along the axis, and one end is fixedly connected to the preloaded guide rail 3, and the other end is fixedly connected to the base 5; Under the action of the elastic restoring force, the first stator group 1 and the second stator group 1' keep in contact with the mover / linear guide rail 2, so that the piezoelectric linear motor has a power-off self-locking function.

[0033]The first stator group 1 and the second stator group 1' are placed side by side and symmetrical along the Y axis. The first stator group 1 and the second stator group 1' are pressed on the mover / linear guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com