Biological treatment method and device for organic wastewater

A biological treatment and organic technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water treatment parameter control, etc., can solve the problem of large footprint, achieve improved solid-liquid separation, and improve treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

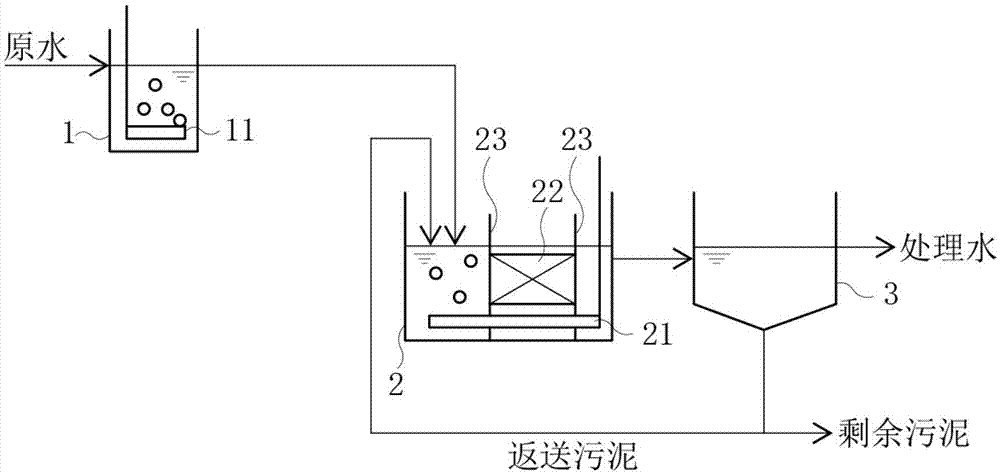

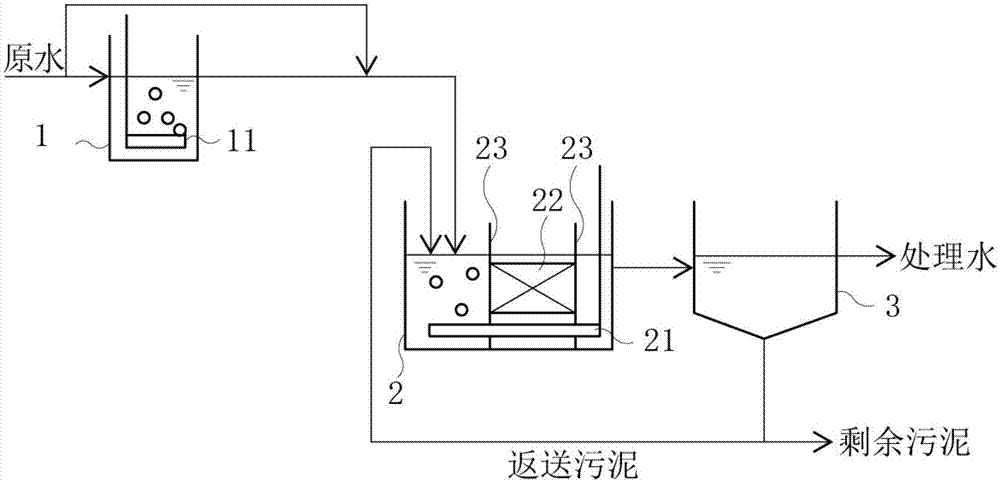

[0067] Such as figure 1 As shown, the organic wastewater treatment of the present invention was carried out using an experimental device connecting a first biological treatment tank 1 with a capacity of 36 L, a second biological treatment tank 2 with a capacity of 150 L, and a sedimentation tank 3 with a capacity of 50 L. Raw water contains COD Cr : 2000mg / L, BOD: 1280mg / L artificial matrix.

[0068] The treatment conditions of each biological treatment tank are as follows:

[0069]

[0070] DO: 0.5mg / L

[0071] BOD volume load: 7.7kg-BOD / m 3 / sky

[0072] HRT: 4 hours

[0073] pH: 7.0

[0074]

[0075] DO: 4mg / L

[0076] Carrier filling rate: 2%

[0077] HRT: 17 hours

[0078] SRT: 25 days

[0079] pH: 7.0

[0080] As the carrier 22 of the second biological treatment tank 2, plate-shaped polyurethane foam (100cm×30cm×1cm / 1 block) is used, and the bottom and left and right sides fixed on the tank wall.

[0081] Also, the BOD volume load of the whole device is ...

Embodiment 2

[0089] As raw water, use COD containing Cr : 670mg / L, BOD: 430mg / L artificial matrix, relative to the BOD volume load of the first biological treatment tank: 2.6kg-BOD / m 3 / day, the overall BOD volume load is: 0.5kg-BOD / m 3 / day (0.78kg-COD Cr / m 3 / day), HRT21 hours, the soluble BOD sludge load of the sludge in the second biological treatment tank relative to the tank is 0.025kg / kg-MLSS / day, operates with the above-mentioned conditions, in addition, with embodiment 1 Treated under the same conditions.

[0090] As a result, the sludge flocs in the second biological treatment tank and the filter-predatory microfauna (bellworms, bdelloids) fixed on the carrier are prioritized, and the sludge conversion rate is 0.08kg-MLSS / kg-COD Cr . The treated water is soluble COD Cr The concentration is less than 30mg / L, and SS is less than 10mg / L. During the test, it always maintains a good condition.

Embodiment 3

[0096] As raw water, use COD containing Cr : 6700mg / L, BOD: 4350mg / L artificial matrix, relative to the BOD volume load of the first biological treatment tank: 17.5kg-BOD / m 3 / day, overall BOD volume load: 5kg-BOD / m 3 / day, the first biological treatment tank HRT6 hours, the second biological treatment tank HRT15 hours, the carrier filling rate of the second biological treatment tank 5%, SRT50 days, the soluble BOD sludge of the second biological treatment tank relative to the sludge in the tank The load was 0.05 kg / kg-MLSS / day, and the operation was performed under the above-mentioned conditions, and the treatment was performed under the same conditions as in Example 1 except that.

[0097] As a result, the sludge flocs in the second biological treatment tank and the filter-predatory microfauna (bellworms, bdelloids) fixed on the carrier were prioritized, and the sludge conversion rate was 0.09kg-MLSS / kg-COD Cr . The treated water is soluble COD Cr The concentration is l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap