High-efficiency nut shelling machine

A high-efficiency, shell-breaking machine technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low processing efficiency, high labor intensity, and people can't afford it, so as to achieve the best shell-breaking effect and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

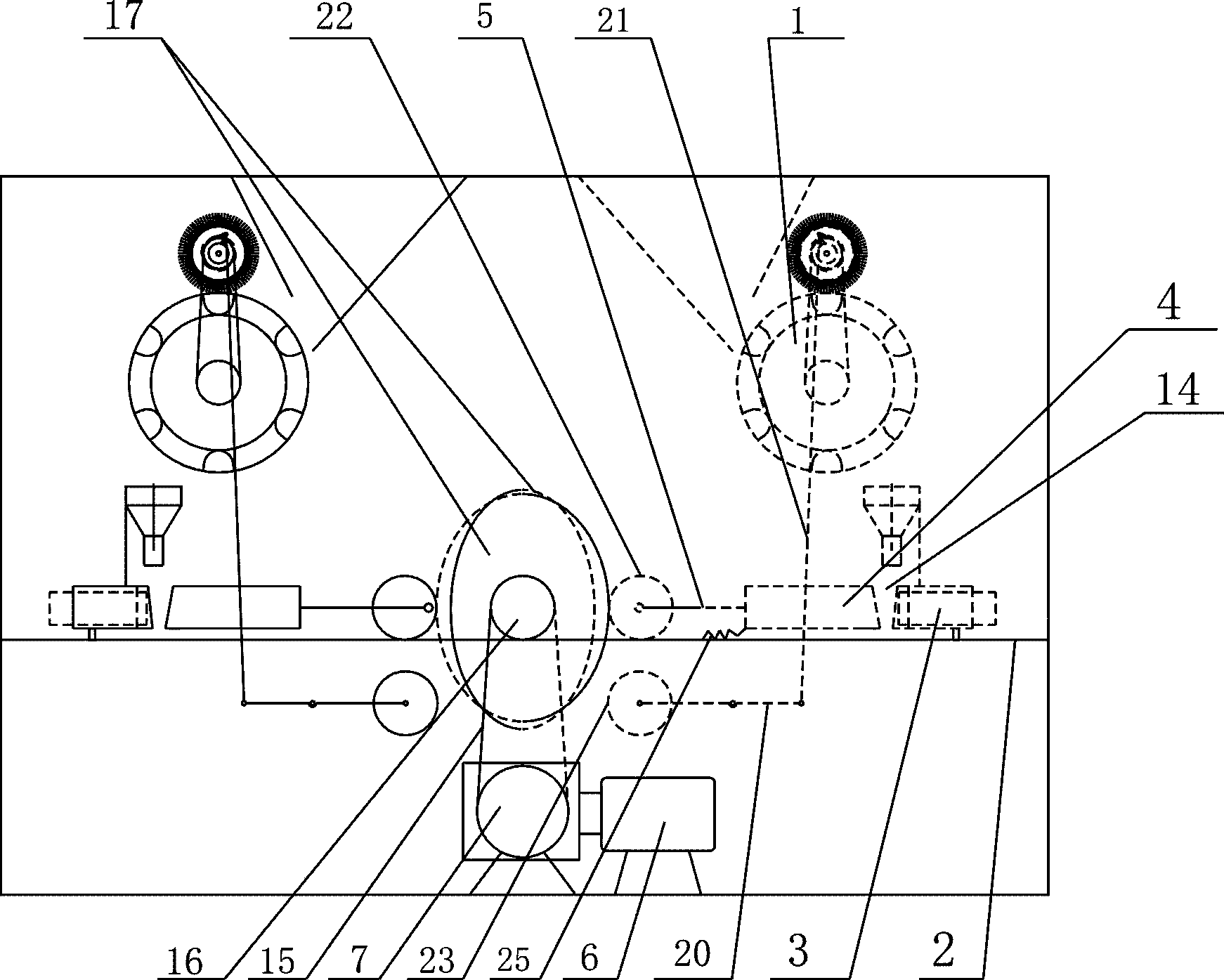

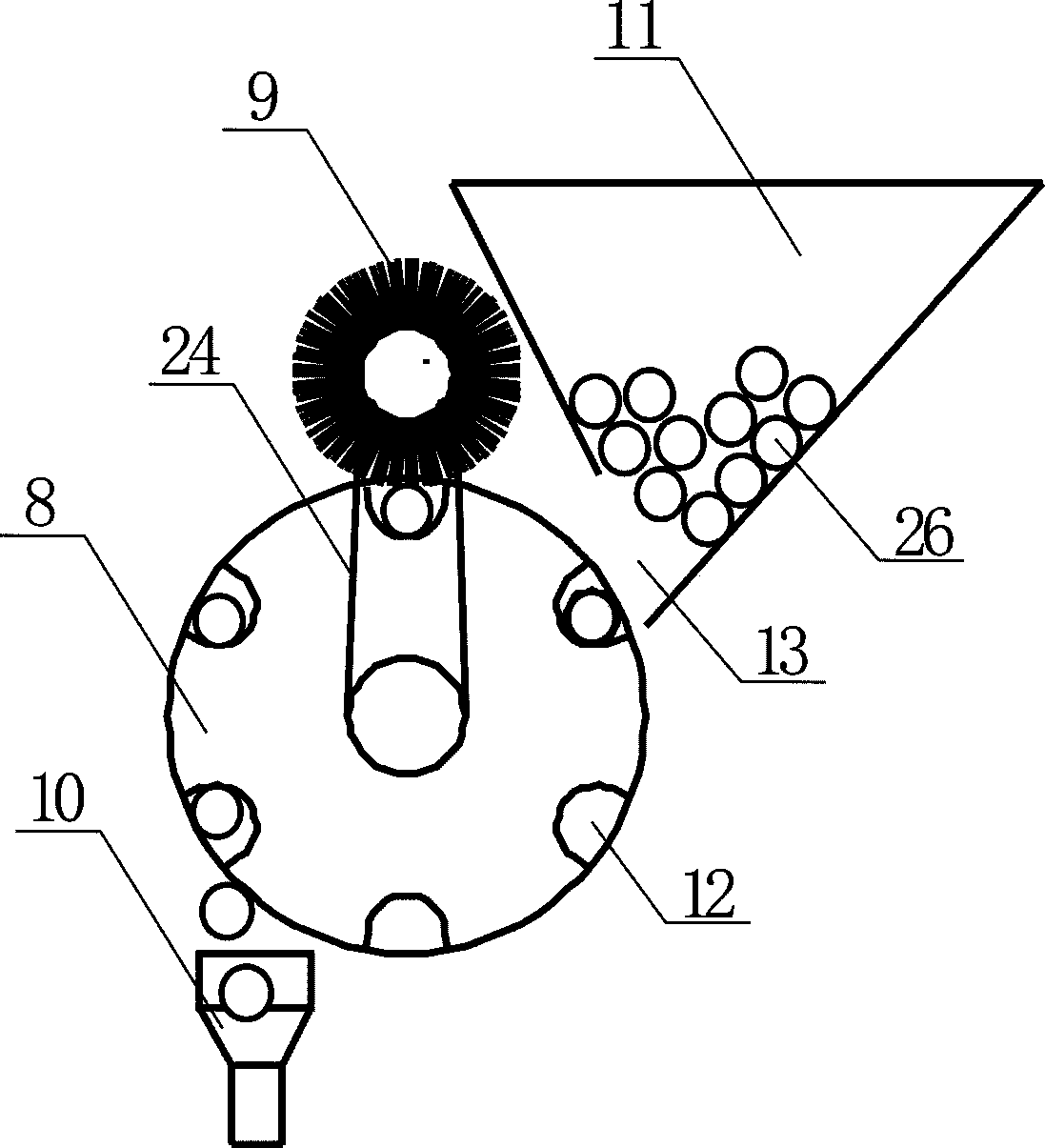

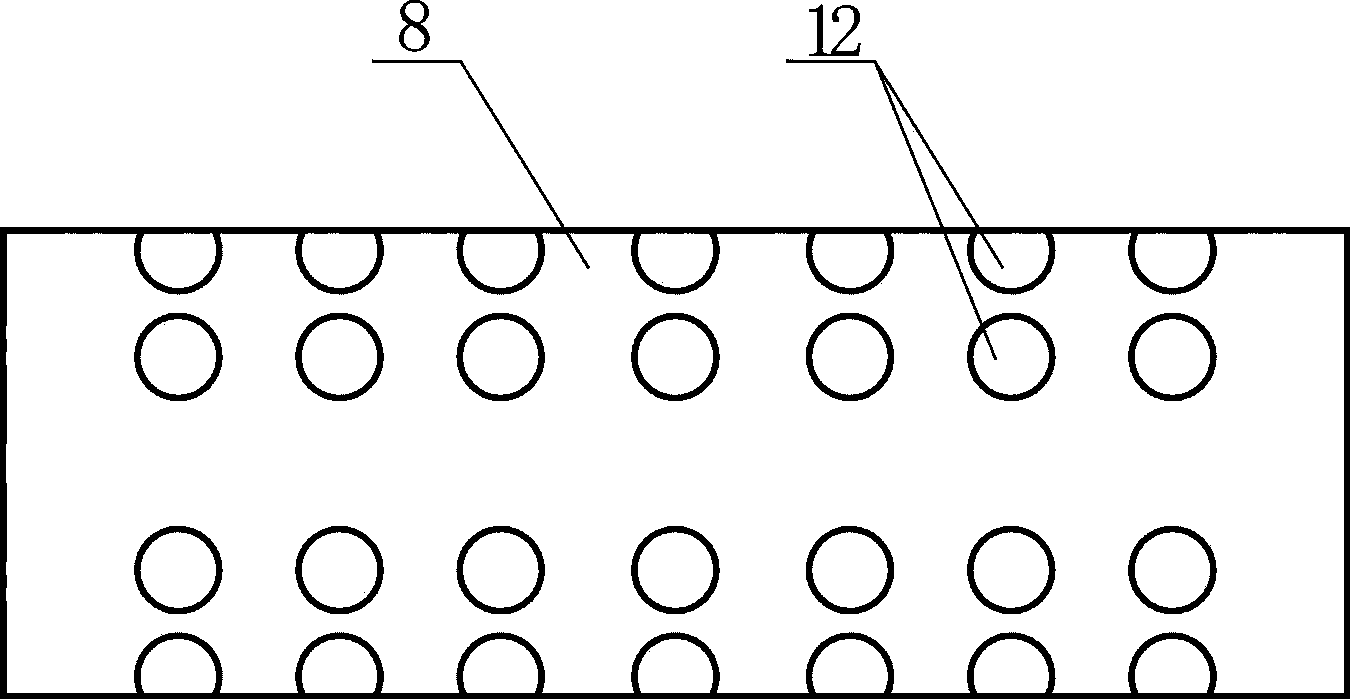

[0017] Such as figure 1 , 2 , 3, and 4, the high-efficiency nut sheller is mainly composed of a fruit extractor 1, a frame 2, a fixed blade 3, a moving blade 4, a moving knife holder 5, a motor 6 and a gearbox 7. The blade 3 is horizontally arranged on the frame 2, the movable knife rest 5 is arranged on the frame 2, the movable blade 4 on the movable knife rest 5 corresponds to the fixed blade 3 and there is a certain gap 14 therebetween, the fruit extractor 1. It is mainly composed of a fruit taking roller 8, a brush roller 9, a hopper 10 and a fruit box 11. The surface of the fruit taking roller 8 is distributed with a plurality of fruit receiving grooves 12 at intervals along the axial direction, and the plurality of fruit receiving grooves 12 form One row, the surface of the fruit-taking roller is distributed with multiple rows of fruit receiving grooves at intervals along the circumferential direction, the fruit box 11 is arranged on the side top of the fruit-taking rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com