Polypropylene-microporous-membrane folded filter core

A polypropylene microporous membrane and pleated filter element technology, which is applied in the field of filter elements, can solve the problems of expensive filter membranes, medium shedding, and low flux, and achieve a wide range of chemical compatibility, ensure product performance, and uniform pore size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

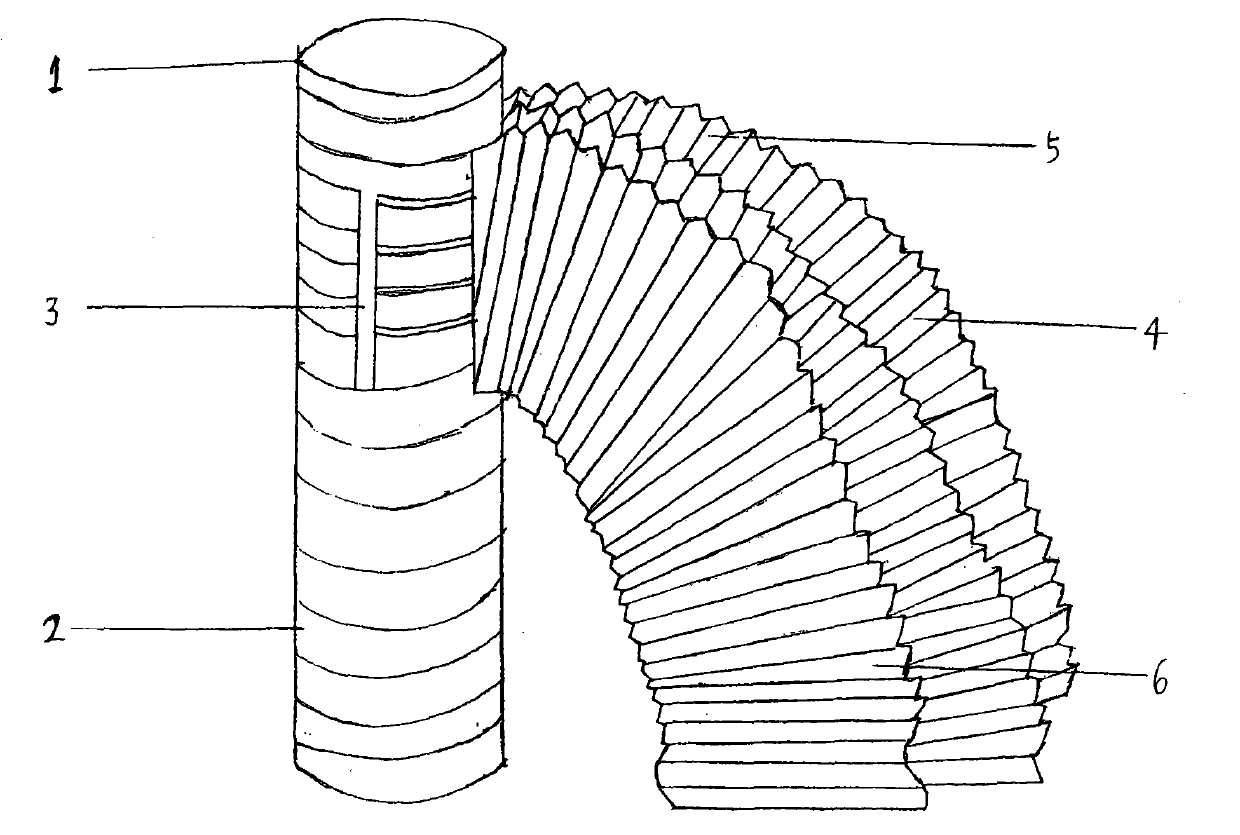

[0007] A polypropylene microporous membrane folded filter element, comprising flat-pressed double openings 1, a shell 2, a central rod 3, a folded filter element 4, a diversion support layer 5, and a filter membrane 6, and the flat-pressed double openings 1 are located at both ends of the shell 2, There is a diversion support layer 5 under the casing 2, a filter membrane 6 is arranged under the diversion support layer 5, a center rod 3 is arranged in the center of the filter membrane 6, and a folded filter element 4 is arranged in the center rod 3, and the membrane core is placed in the membrane stack Inside, the water flow that needs to be treated is opened, one end of the double opening passes through the flat pressure, enters the diversion support layer from the shell, and then enters the center rod through the filter membrane, the folded filter membrane in the center of the center rod runs repeatedly, and then the other end of the double opening is pressed by the flat pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com