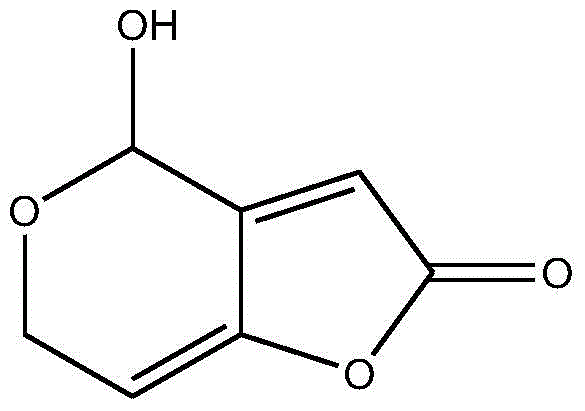

A super-highly cross-linked macroporous adsorption resin suitable for the removal of patulin

An ultra-high cross-linking and patulin technology, applied in the field of polymer chemistry, can solve the problems of low patulin removal rate, unsatisfactory requirements, and low processing capacity, and achieve potential hazards and small average pore size , High removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

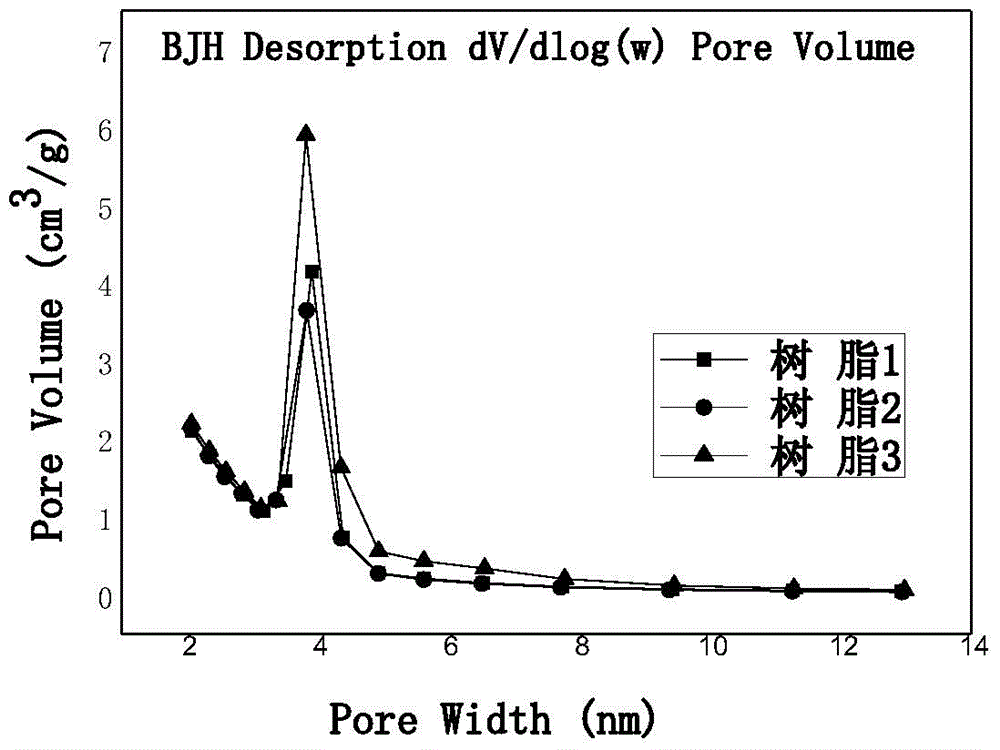

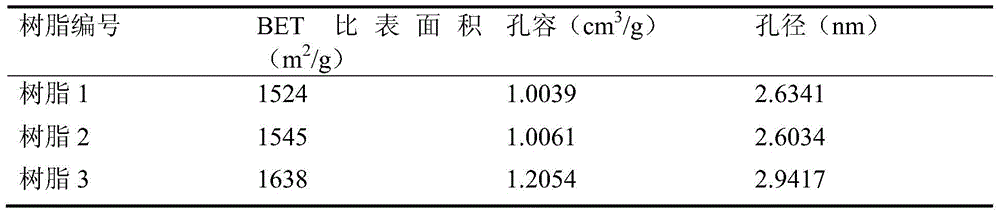

Embodiment 1

[0045] (1) Preparation of low-crosslinked macroporous polystyrene white balls

[0046] Take the following components by weight:

[0047] 88 parts of styrene monomer

[0048] Divinylbenzene 5 parts

[0049] 70 parts of toluene

[0050] Benzoyl peroxide 0.5 parts

[0051] The oil phase composed of the above components mixed uniformly was placed in water together, reacted for 18 hours at 60°C, and suspended polymerization to obtain cross-linked macroporous polystyrene white balls with a cross-linking degree of 4%.

[0052] Gelatin is added to the water, water and gelatin form a dispersion medium, the amount of gelatin is 0.5% of the weight of the dispersion medium, and the volume ratio of the amount of dispersion medium to the oil phase is 1:1;

[0053] (2) Preparation of chloromethylated macroporous polystyrene resin

[0054] The macroporous polystyrene white ball obtained in step (1) was reacted with chloromethyl ether at 37°C for 24 hours under the catalysis of anhydrous ...

Embodiment 2

[0061] (1) Preparation of low-crosslinked macroporous polystyrene white balls

[0062] Take the following components by weight:

[0063] 90 parts of methyl styrene monomer

[0064] Divinylbenzene 10 parts

[0065] 100 parts of 200# gasoline

[0066] 1 part benzoyl peroxide

[0067] The oil phase composed of the above components mixed uniformly was placed in water together, and reacted for 16 hours at 80°C to suspend polymerization to obtain cross-linked macroporous polystyrene white balls with a cross-linking degree of 8%.

[0068] Polyvinyl alcohol is added to the water, water and polyvinyl alcohol form a dispersion medium, the amount of polyvinyl alcohol is 1% of the weight of the dispersion medium, and the volume ratio of the amount of dispersion medium to the oil phase is 1:2;

[0069] (2) Preparation of chloromethylated macroporous polystyrene resin

[0070] The macroporous polystyrene white ball obtained in step (1) was reacted with chloromethyl ether at 40°C for 18...

Embodiment 3

[0077] (1) Preparation of low-crosslinked macroporous polystyrene white balls

[0078] Take the following components by weight:

[0079] 97 parts of styrene monomer

[0080] Divinylbenzene 13 parts

[0081] 100 parts of toluene

[0082] 50 parts of liquid paraffin

[0083] Benzoyl peroxide 1.5 parts

[0084] The oil phase composed of the above components mixed uniformly was placed in water together, reacted for 14 hours at 90°C, and suspended polymerization to obtain cross-linked macroporous polystyrene white balls with a cross-linking degree of 9.5%.

[0085] Carboxymethyl cellulose is added to the water, water and carboxymethyl cellulose form the dispersion medium, the amount of carboxymethyl cellulose is 2% of the weight of the dispersion medium, and the volume ratio of the dispersion medium to the oil phase is 1: 3;

[0086] (2) Preparation of chloromethylated macroporous polystyrene resin

[0087] The macroporous polystyrene white ball obtained in step (1) was reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com