High-precision positioning device for reinforcement straightening cutting-off machine

A technology of positioning device and cutting machine, applied in the field of steel bar straightening and cutting machine, can solve the problems of steel bar cutting length error, increase production cost, affect product quality, etc., and achieve the effects of safe and convenient use, improved work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

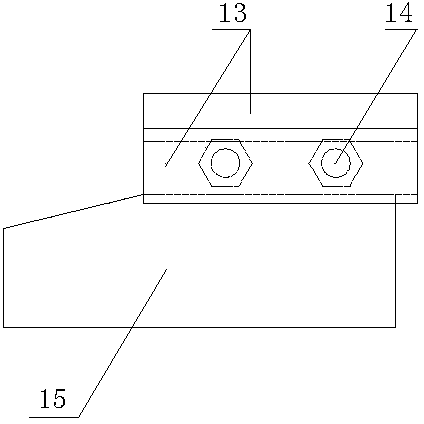

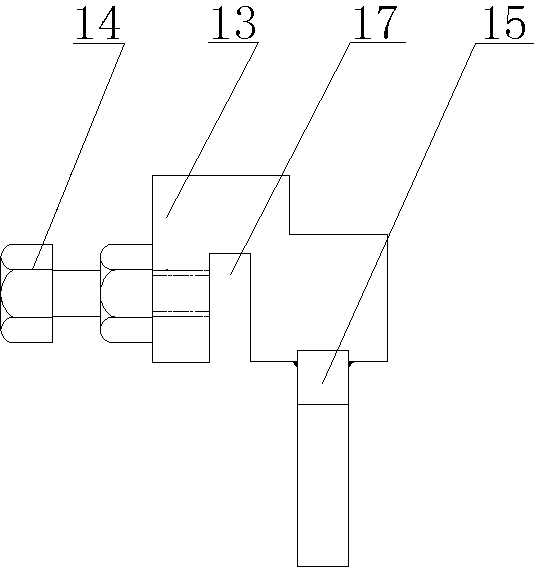

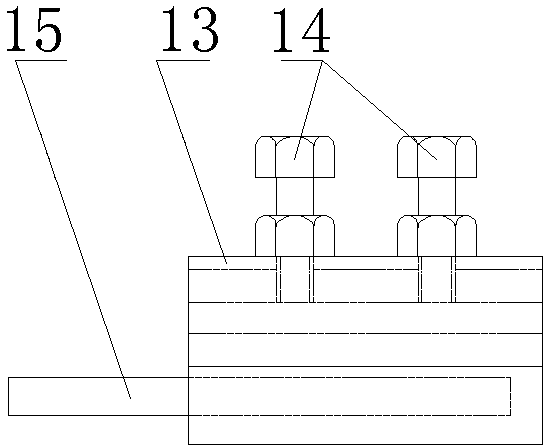

[0017] From Figure 1-Figure 6 As can be seen in the figure: a high-precision positioning device for a steel bar straightening and cutting machine (referred to as a high-precision positioning device), including a main box 18 of a steel bar straightening and cutting machine, a frame 19 and a guide rail 12 for installing the high-precision positioning device, This guide rail 12 is installed on the upper part of the frame 19 located on the right side of the main chassis 18. It is characterized in that: the high-precision positioning device for the steel bar straightening and cutting machine also includes a baffle base 13, a baffle 15 and a fixing bolt II 14. The baffle seat 13 is a cuboid, and the front upper part of the baffle seat 13 is provided with a rectangular straight-through slit left and right. card slot 17, and make the groove width of the straight-through card slot 17 slightly larger than the width of the guide rail 12, and set left and right screw holes on the rear wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com