Equalizing groove milling device

A milling device and indexing plate technology, applied in the field of machinery, can solve the problems of high labor intensity, low production efficiency, poor precision, etc., and achieve the effect of low labor intensity, high work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

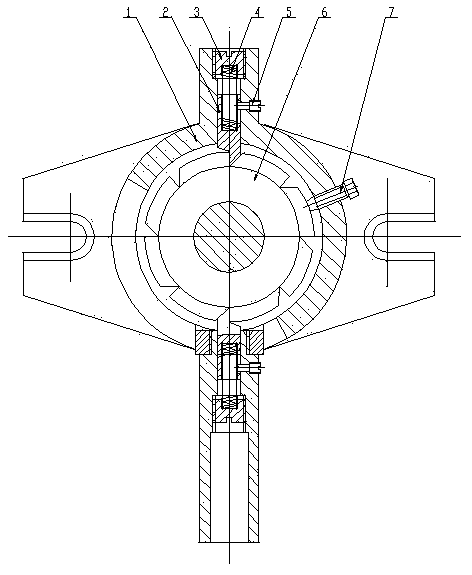

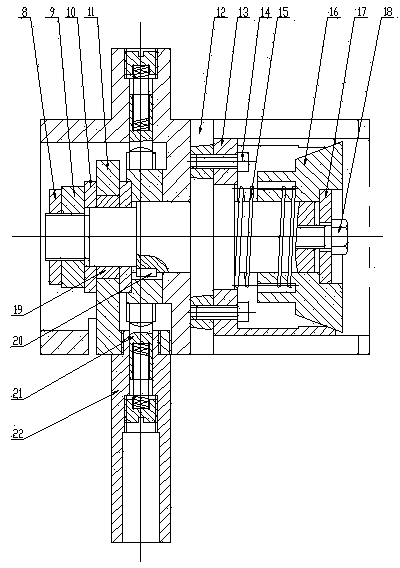

[0011] The present invention will be further described below in conjunction with accompanying drawing: Equal groove milling device, comprises the base 1 that is fixedly installed on the milling machine workbench, on the base 1 is equipped with indexing plate 6 by locking screw 7, the end hole of base 1 both sides There are limit pins I2 and limit pin II21 respectively inside, anti-rotation screws 5 are respectively fixed on both ends of the base 1, and the front ends of anti-rotation screws 5 are inserted into the axial long grooves of limit pin I2 and limit pin II21 to prevent limit When the position pin rotates, spring I4 is installed on both limit pin I2 and limit pin II21, and the upper end of spring I4 is provided with an adjustment screw 3. Inserted into the groove of the index plate 6, the head of the limit pin is in the shape of sharp teeth with a slope, which can not only limit the rotation of the index plate 6 but also drive the index plate 6 to rotate. When the handl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com