Preparation method of aerospace hyperbranched polysiloxane polyimide transparent hybrid thin films

A technology of polysiloxane polyimide and film, which is applied in the field of preparation of hyperbranched polysiloxane polyimide transparent hybrid film for space, can solve the problem that the uniformity of coating thickness is difficult to be effectively controlled, The expansion and shrinkage of the adhesion interface is not uniform, and the coating cannot be guaranteed to be intact, etc., to achieve the effect of low preparation cost, conducive to large-scale industrial production, and excellent intrinsic anti-atomic oxygen performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

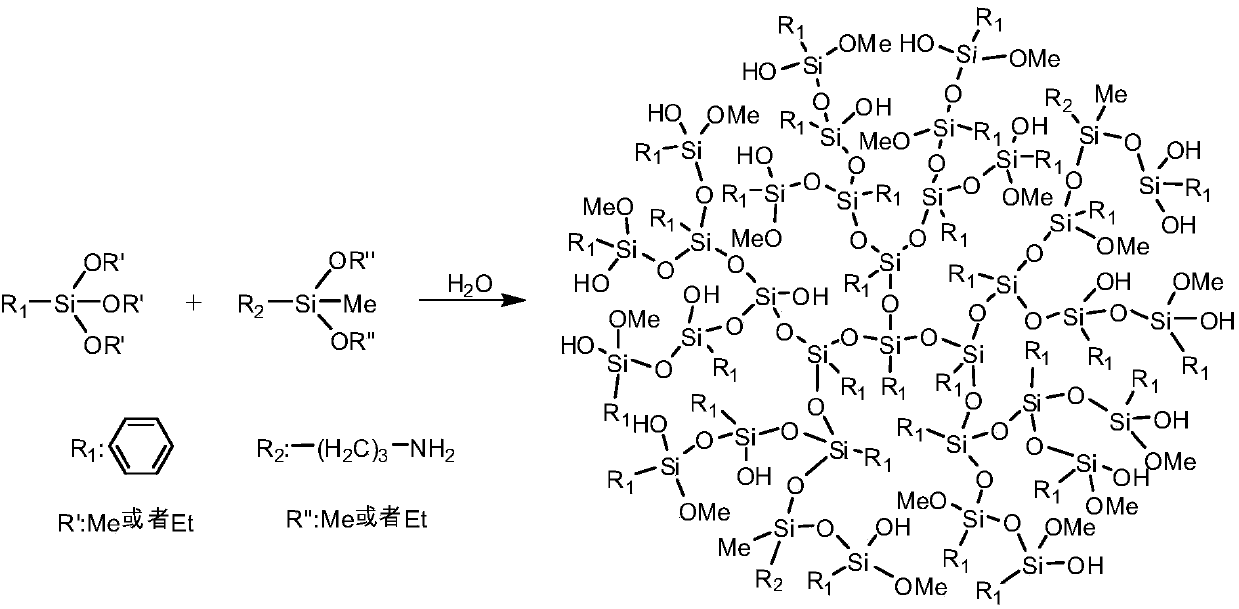

[0033] Example 1: Add 35g N,N-dimethylacetamide (DMAc), 19.83g phenyltrimethoxysilane and 0.38g aminopropylmethyldiethoxysilane to a container equipped with a magnetic stirrer in sequence , And start stirring at the same time to cool down the system. When the temperature dropped to 5°C, 5.5 g of distilled water was dropped into the system within 1 hour. Keep the reaction conditions unchanged, continue to stir for 1 hour, raise the temperature to 50°C, and stir for 3 hours. After the reaction is completed, the temperature is controlled at 65° C. and the pressure is -0.075 MPa by rotary evaporation. The small molecule volatiles generated by the reaction are removed to obtain HBPSi with an amino group content of 0.16 mmol / g.

Embodiment 2

[0034] Example 2: Add 20g of N,N-dimethylformamide (DMF), 24.04g of phenyltriethoxysilane and 0.76g of aminopropylmethyldiethoxy to a container equipped with a magnetic stirrer. Silane, while stirring and cooling the system. When the temperature dropped to 6°C, 6g of distilled water was dropped into the system within 1h. Keep the reaction conditions unchanged, continue to stir for 1 hour, raise the temperature to 50°C, and stir for 3 hours. After the reaction is completed, the temperature is controlled at 70° C. and the pressure is -0.075 MPa by rotary evaporation. The small molecule volatiles generated by the reaction are removed to obtain HBPSi with an amino group content of 0.32 mmol / g.

Embodiment 3

[0035] Example 3: Add 22g DMAc, 19.83g phenyltrimethoxysilane and 1.15g aminopropylmethyldimethoxysilane to a container equipped with a magnetic stirrer in sequence, and start stirring at the same time to cool the system. When the temperature dropped to 4°C, 4.8 g of distilled water was dropped into the system within 1 hour. Keep the reaction conditions unchanged, continue to stir for 1 hour, raise the temperature to 50°C, and stir for 3 hours. After the reaction is completed, the temperature is controlled at 60° C. and the pressure is -0.075 MPa by rotary evaporation. The small molecule volatiles generated by the reaction are removed to obtain HBPSi with an amino group content of 0.46 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com