A kind of antirust aluminum alloy material

A technology for aluminum alloy materials and raw materials, applied in the field of new rust-proof aluminum alloy materials, can solve problems such as the problem of mechanical properties of aluminum alloys that cannot be fundamentally solved, and achieves hindering the recrystallization process, good corrosion resistance, and improving strength and plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

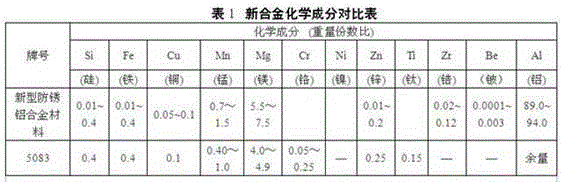

[0025] A novel antirust aluminum alloy material, the raw material of described aluminum alloy material comprises Si, Fe, Cu, Mn, Mg, Zn, Zr, Be and Al, and the weight and number ratio of described raw material is:

[0026] Si 0.01~0.4

[0027] Fe 0.01~0.4

[0028] Cu 0.01~0.1

[0029] Mn 0.7~1.5

[0030] Mg 5.5~7.5

[0031] Zn 0.001~0.2

[0032] Zr 0.02~0.12

[0033] Be 0.0001~0.003

[0034] Al 89.0~94.0.

[0035] The unit of weight used in this embodiment is kilogram, and may also be ton.

[0036] All raw materials described in this example are of industrial grade.

[0037] In this embodiment, each raw material can be flexibly combined within the given proportioning range, which will not be enumerated here.

Embodiment 2

[0039] This embodiment is a preferred solution on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. content, which will not be repeated here.

[0040] The raw material of the aluminum alloy material of the present embodiment comprises Si, Fe, Cu, Mn, Mg, Zn, Zr, Be and Al, and the weight and number ratio of described raw material is:

[0041] Si 0.4

[0042] Fe 0.4

[0043] Cu 0.1

[0044] Mn 1.1

[0045] Mg 6.5

[0046] Zn 0.2

[0047] Zr 0.12

[0048] Be 0.003

[0049] Al 91.177.

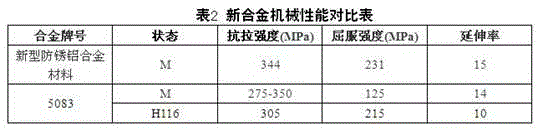

[0050] In order to detect the performance of the new anti-rust aluminum alloy material, the state, tensile strength, yield strength and elongation of the aluminum alloy material described in this embodiment were measured, and compared with the relevant performance of 5083 aluminum alloy, The above detectio...

Embodiment 3

[0054] This embodiment is a preferred solution on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. content, which will not be repeated here.

[0055] The raw material of the aluminum alloy material of the present embodiment comprises Si, Fe, Cu, Mn, Mg, Zn, Zr, Be and Al, and the weight and number ratio of described raw material is:

[0056] Si 0.048

[0057] Fe 0.12

[0058] Cu 0.02

[0059] Mn 0.81

[0060] Mg 7.08

[0061] Zn 0.003

[0062] Zr 0.097

[0063] Be 0.0001

[0064] Al 91.8219.

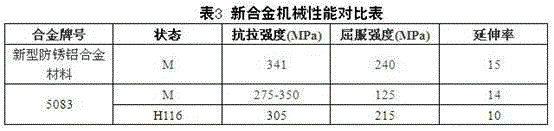

[0065] In order to detect the performance of the new anti-rust aluminum alloy material, the state, tensile strength, yield strength and elongation of the aluminum alloy material described in this embodiment were measured, and compared with the relevant performance of 5083 aluminum alloy, Refer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap