Connecting structure for jacket foundation and underwater pile foundation of offshore wind turbine and grouting method

An offshore wind turbine and connection structure technology, applied in infrastructure engineering, construction, etc., can solve problems affecting the connection quality of jacket foundation pile feet and seabed piles, difficult to ensure the connection strength of jacket and piles, and difficult to control pile feet and seabed piles. Concentricity and other issues can prevent slurry leakage, avoid clogging of grouting ports, and ensure construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

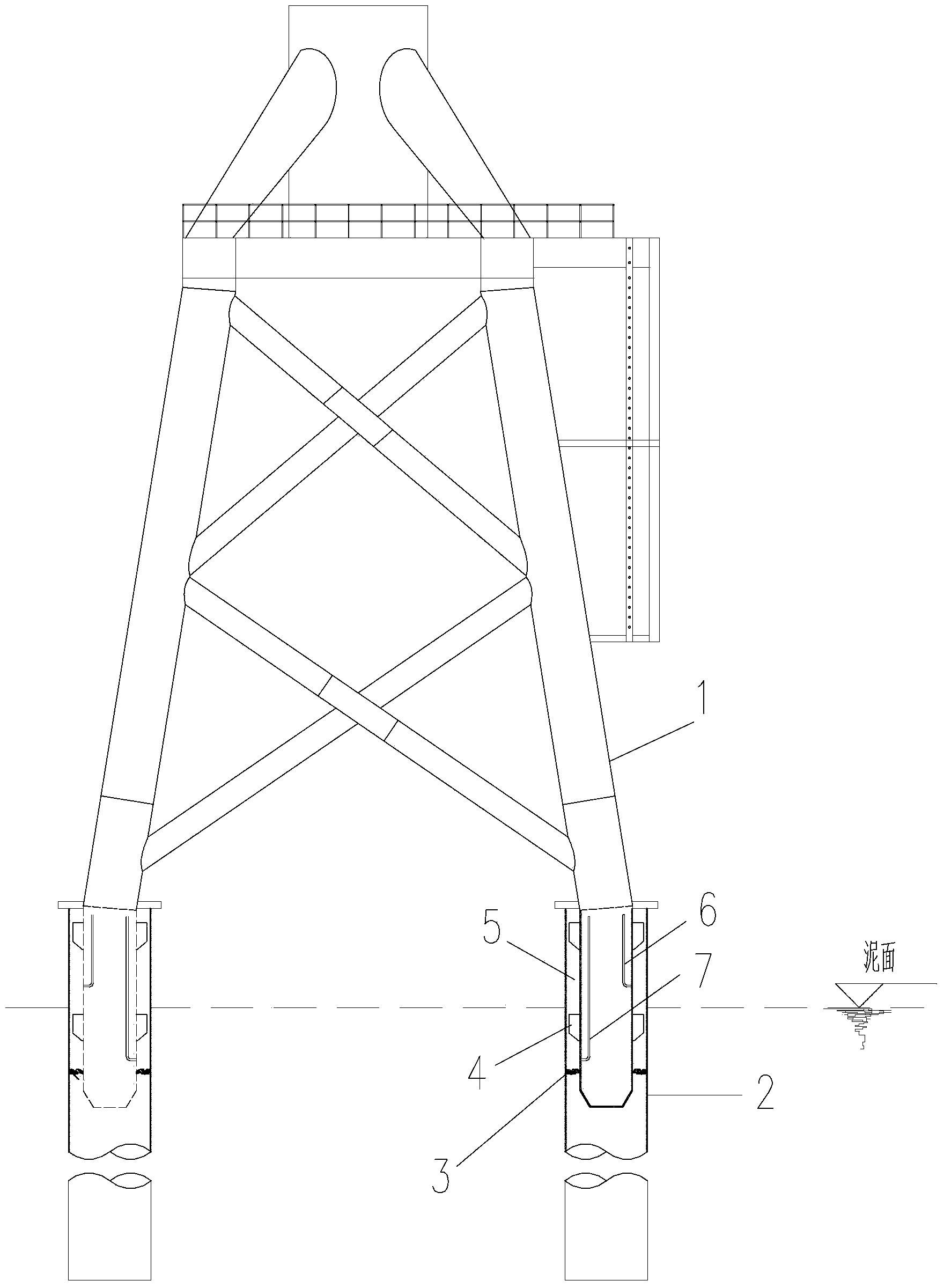

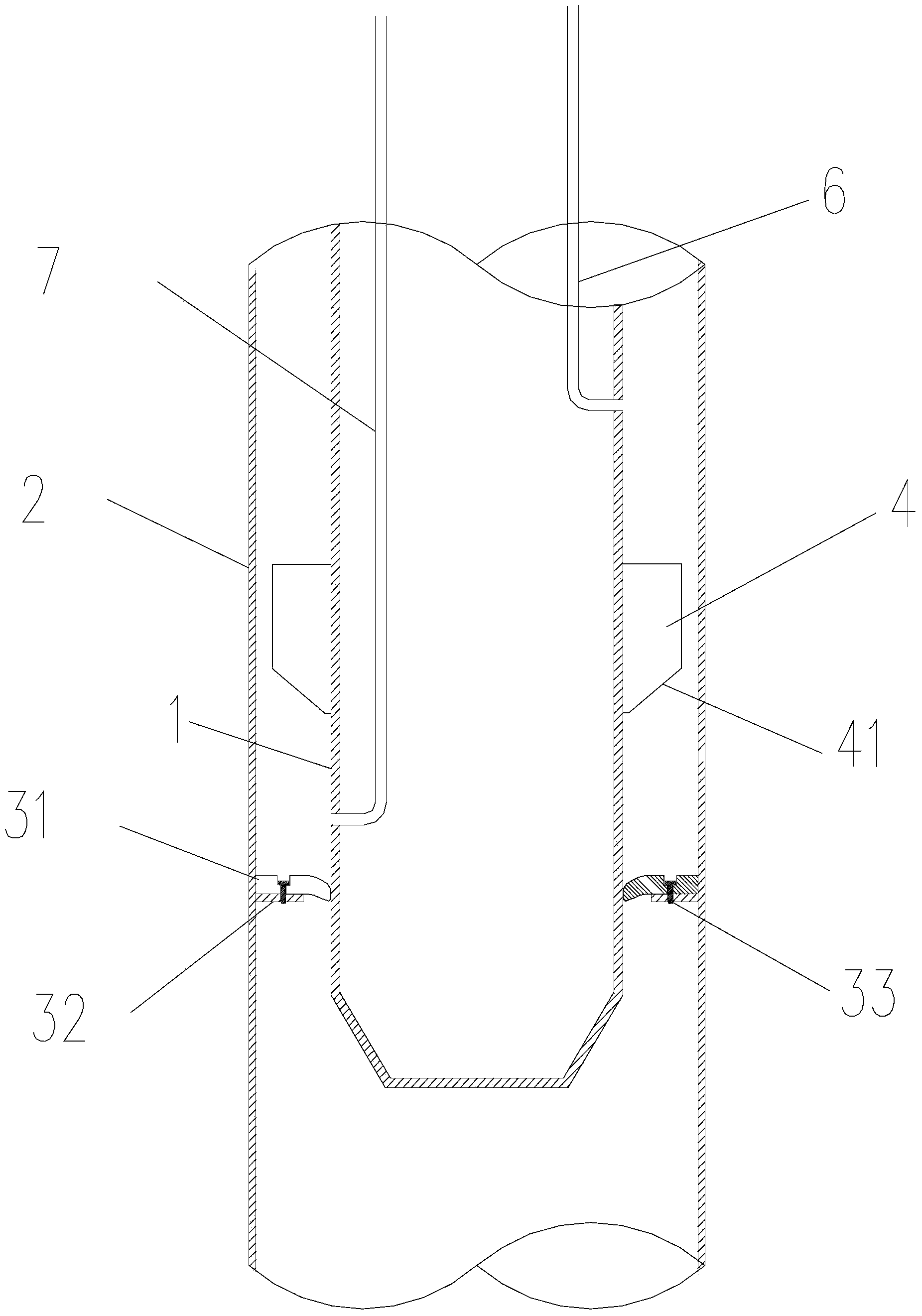

[0023] Such as figure 1 and figure 2 As shown, a connection structure between an offshore wind turbine jacket and a seabed pile foundation, including a cylindrical pile foot 1 on the wind turbine jacket foundation, and a tubular seabed pile 2, the pile foot 1 corresponds to the seabed pile 2 one by one, and the pile foot 1 is inserted through the nozzle of the upper end of the seabed pile 2 and suspended in the seabed pile 2, and there is an annular blocker 3 between the inner wall of the seabed pile 2 and the head where the pile foot 1 is inserted, the annular blocker 3, the pile foot 1 and the seabed The pile 2 forms an annular grouting cavity 5, and the grouting cavity 5 is filled with cement-based high-strength non-shrinkage grouting material (not shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com