Self-spacing double-T-shaped core-steel tube restriction anti-buckling support

An anti-buckling support and core technology, which is applied in the direction of earthquake resistance and building components, can solve the problems of increasing material consumption and man-hours, prone to buckling, and long construction period, so as to avoid excessive connection length, improve compressive bearing capacity, The effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

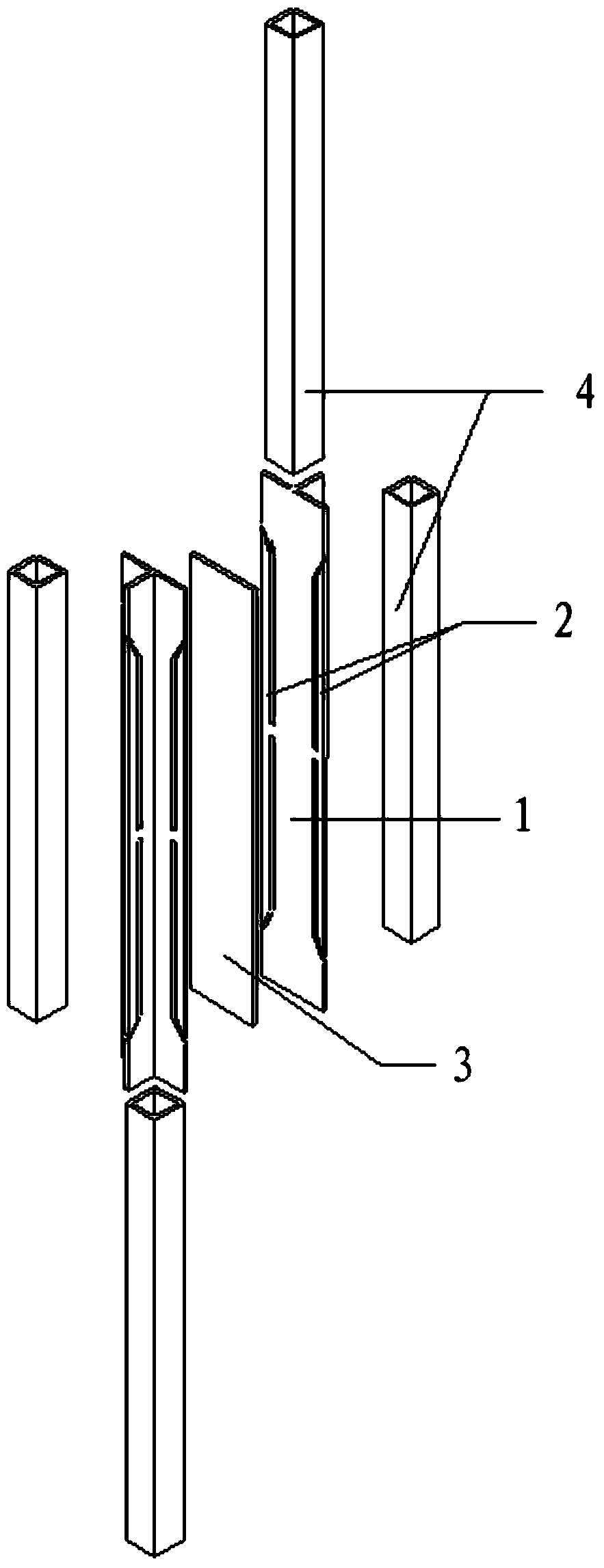

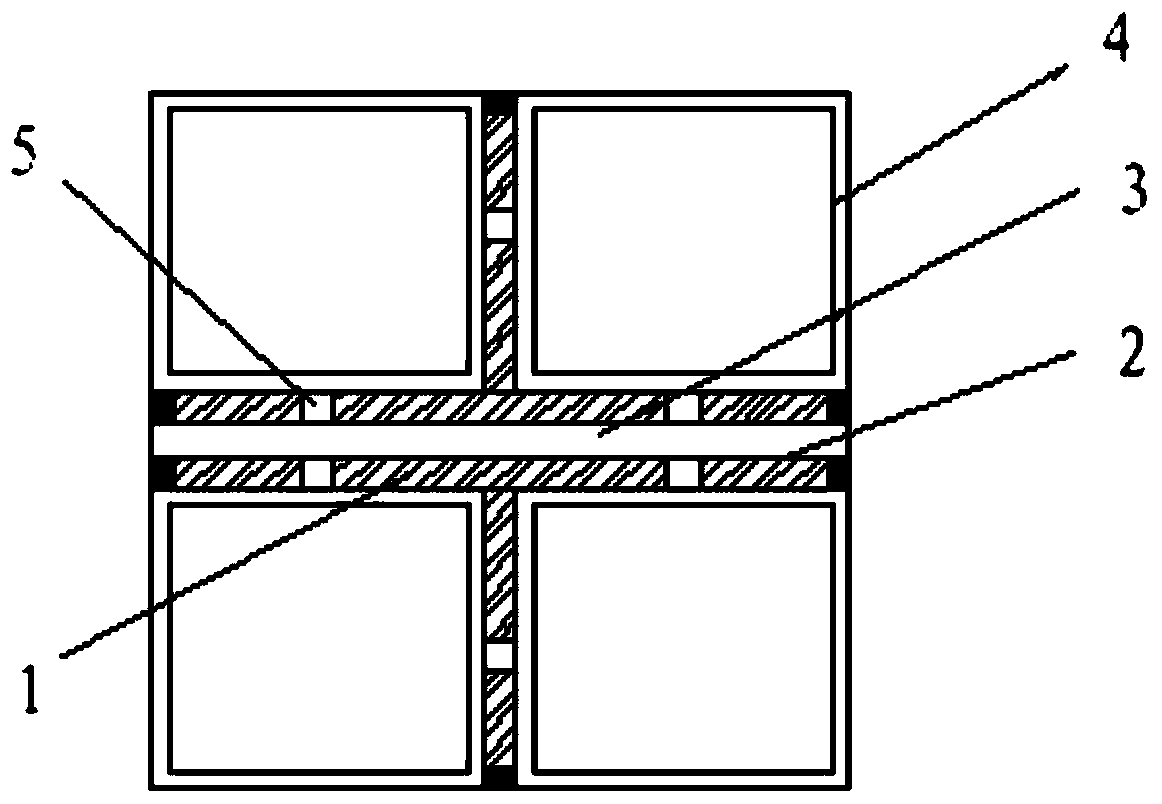

[0024] Such as figure 1 and 2 Shown: a self-limiting double T-shaped core-steel tube constrained buckling-resistant support, including the core force unit 1, the restraint mechanism and the side support unit 2;

[0025] The inner core stress unit is composed of two T-shaped steels with notches;

[0026] The constraining mechanism includes a steel plate constraining unit 3 and a steel pipe constraining unit 4, the steel plate constraining unit 3 is arranged in the middle of the two T-shaped steels, and the steel pipe constraining units 4 are four, respectively arranged in the two T-shaped steels. The four corners of the shaped steel;

[0027] The steel pipe constraining unit 4 includes two cross-section types of cold bending and hot rolling. The steel pipe constraining unit 4 includes two cross-sectional forms of square steel pipe and rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com